Fuel pluger pump for internal combustion ingine

A plunger pump, plunger technology, applied in the field of perfect plunger pump, can solve problems such as surface sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

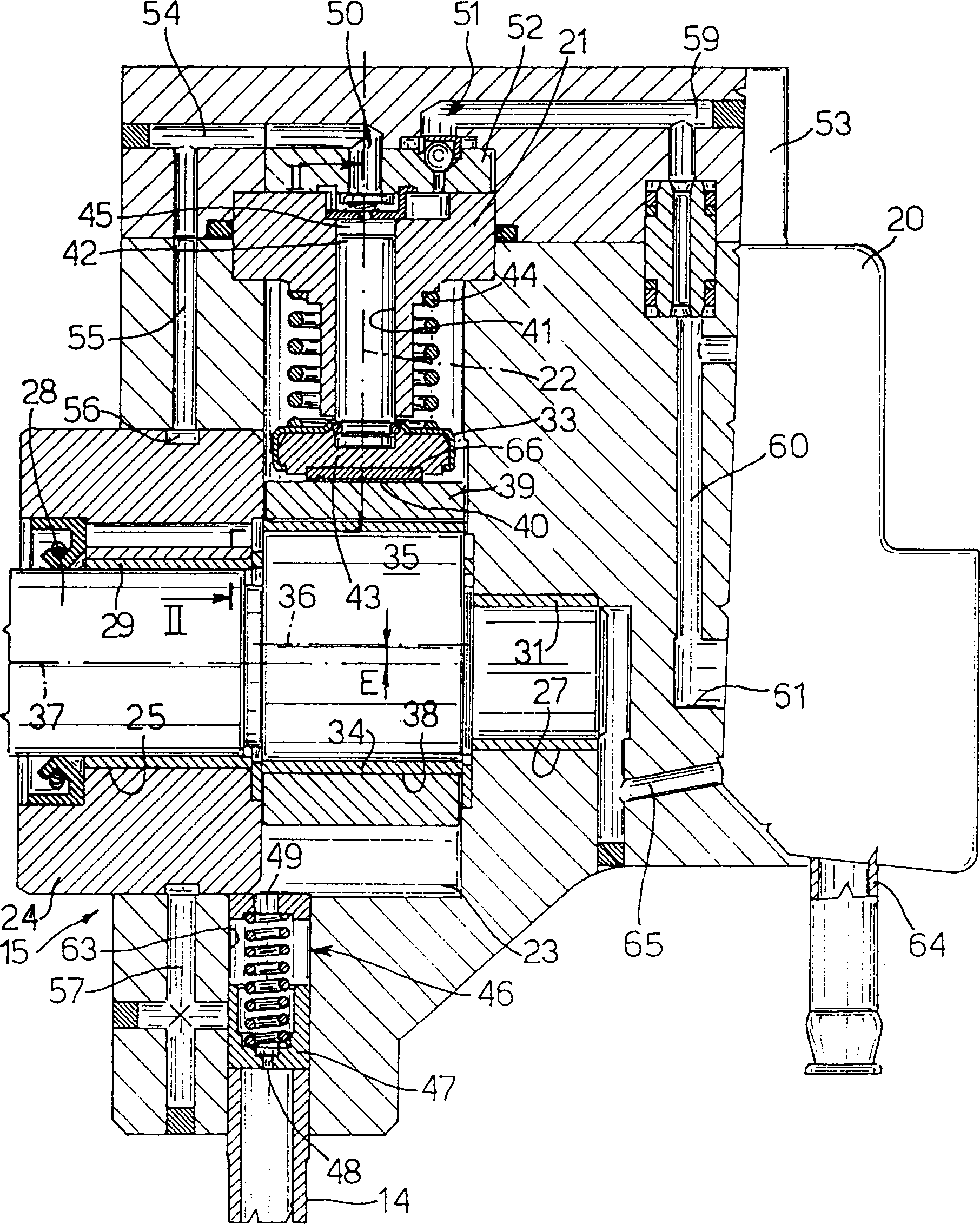

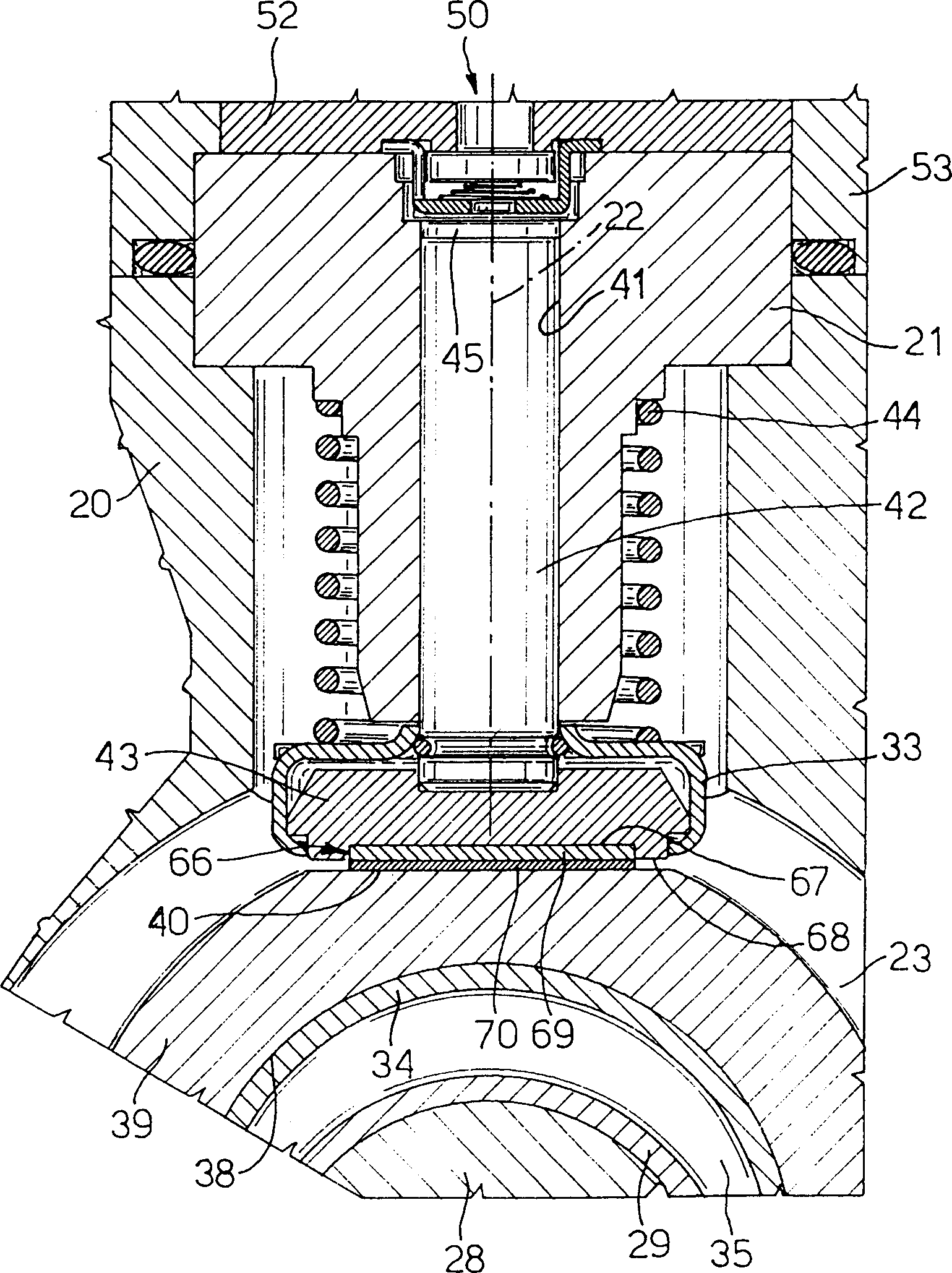

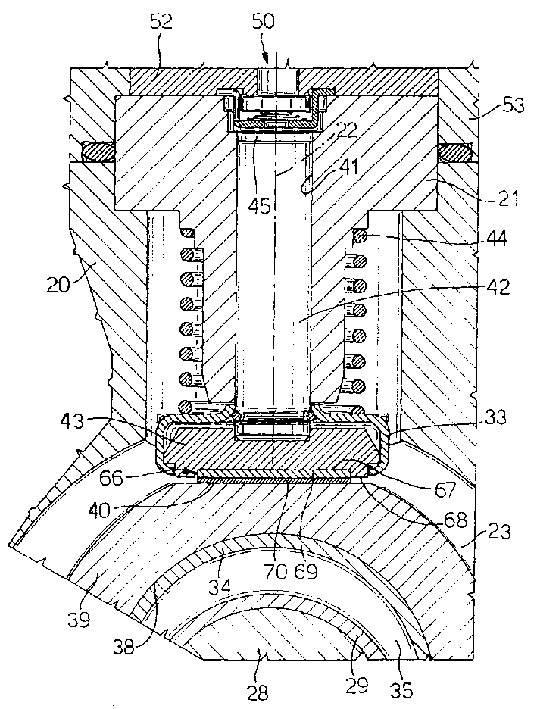

[0013] figure 1 The reference numeral 15 in represents a high-pressure radial piston pump, which is used to provide fuel to an internal combustion engine such as a diesel engine. The piston pump includes three cylinders 21, which are radially arranged in the housing 20, and the clamping between their respective axes 22 The angular interval is 120°. In the center, the housing 20 comprises a cup-shaped interior 23 which is closed by a flange 24 .

[0014] The pump 15 comprises a drive shaft 28 having two parts fitted with respective sliding bearings 29 and 30, through which the shaft 28 rotates in the hole 25 of the flange 24 and in the blind hole 27 of the housing 20; 28 is integrated with the eccentric part 35, and the eccentric part is installed in the cavity 23, and another sliding bearing 34 is assembled, and this sliding bearing cooperates with the inner surface of the hole 38 of the annular cam 39, and the cam controls the pump 15, and the cam 39 is in the eccentric part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com