Preparation method of dissolved gas in transformer oil and preparation device

A technology of dissolving gas in oil and transformer oil, which is applied in the field of transformer oil and can solve problems such as vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

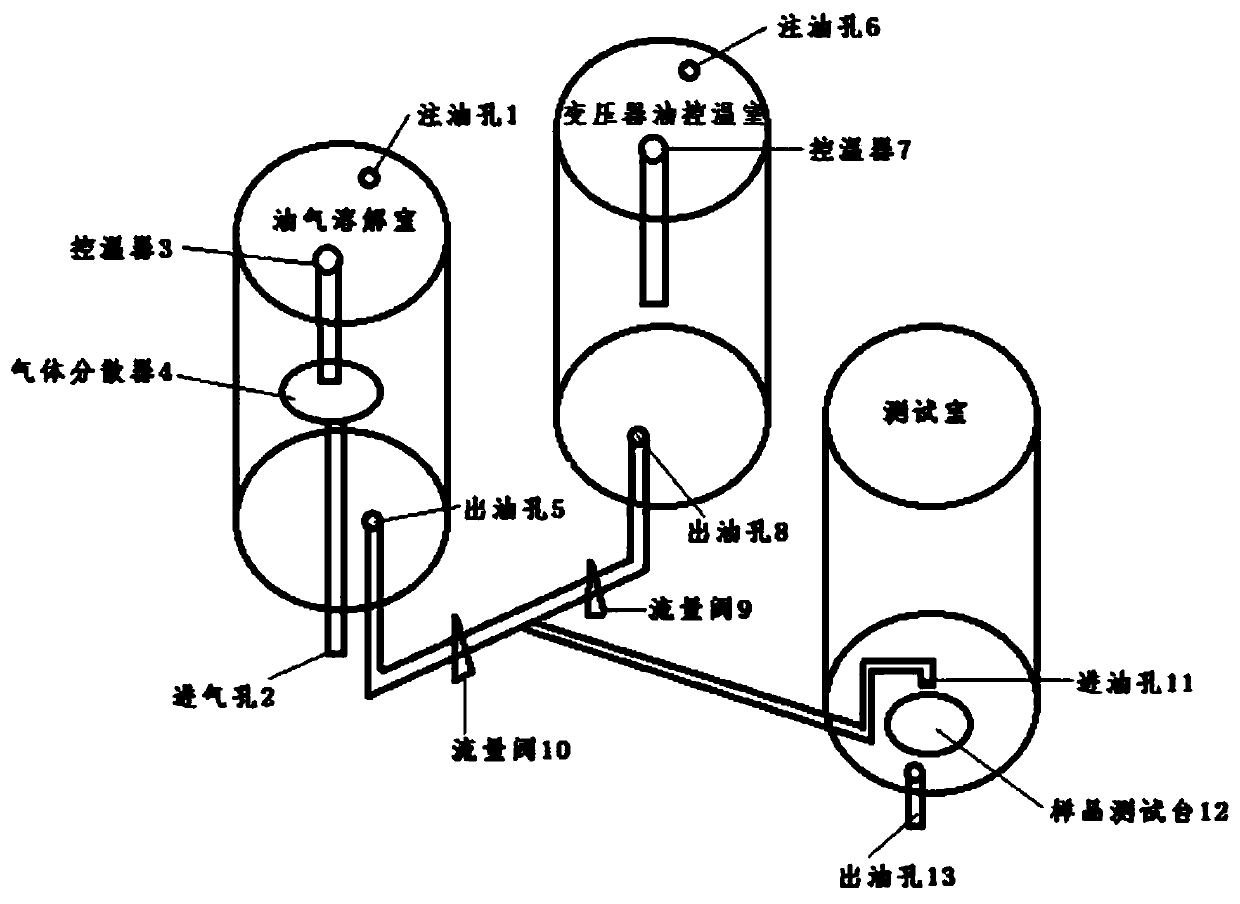

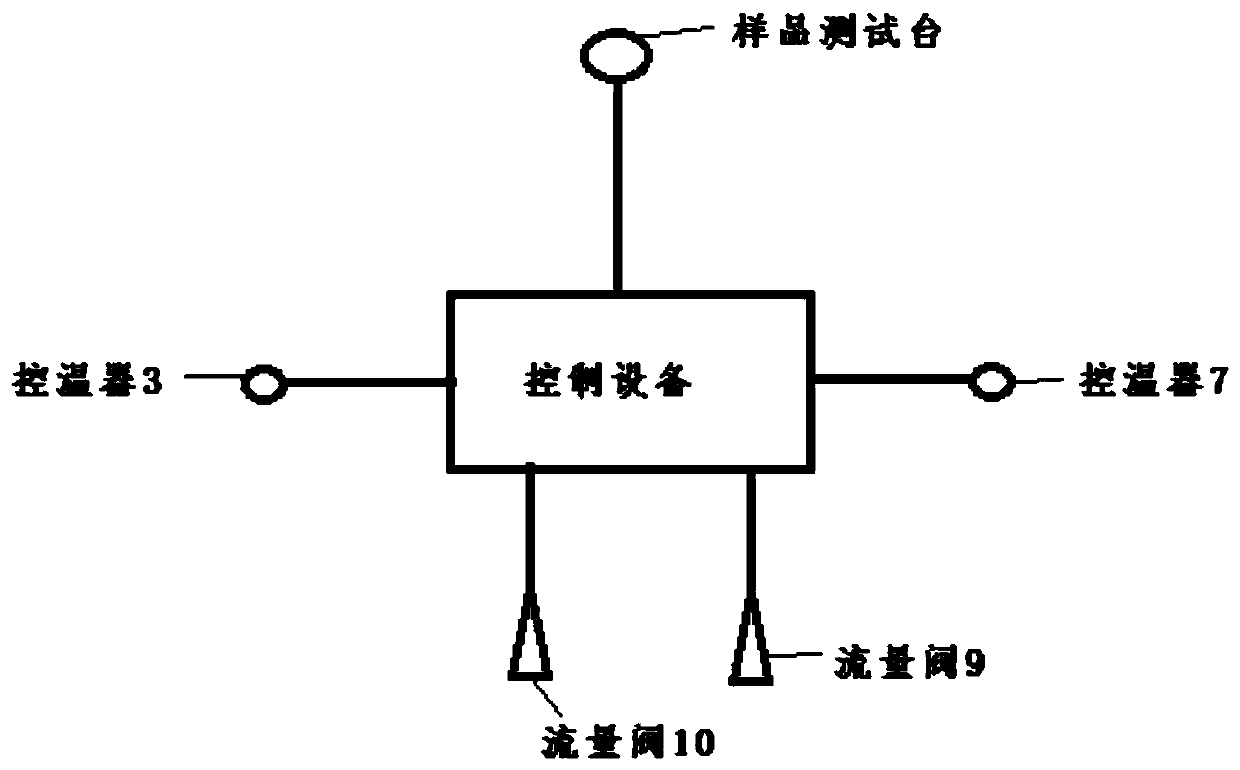

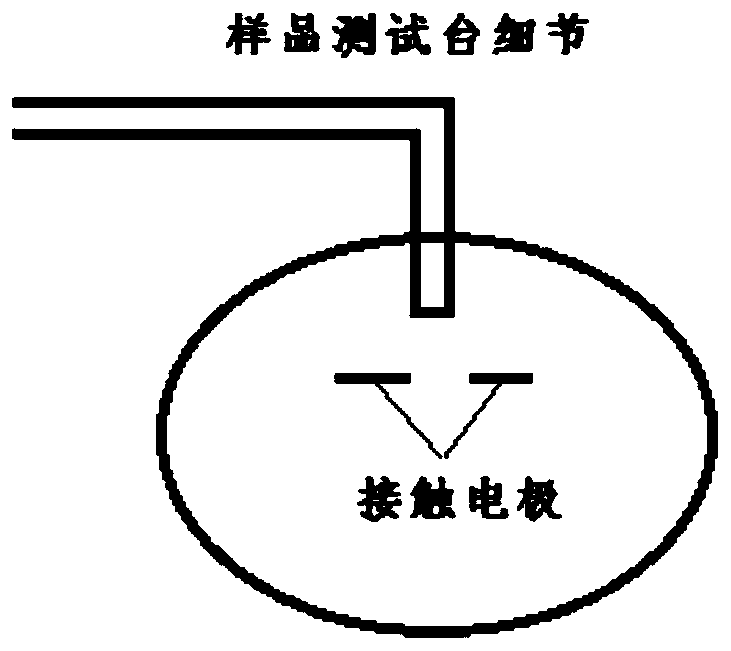

[0037] This embodiment 1 provides a preparation method for dissolved gas in transformer oil, which is to take two parts of the same transformer oil a and b, feed gas into transformer oil a to make the gas in a reach saturation, and then make the gas in a and b The temperature is the same, combined with the Ostwald coefficient derived from Henry's law to control the flow ratio of the oil in a and b, and finally prepare the transformer oil with a specified dissolved gas concentration.

[0038] As a further refinement, the Ostwald coefficient is dependent on temperature and its formula is:

[0039]

[0040] T: actual temperature;

[0041] L 0 : Ostwald coefficient of oil at 273K;

[0042] d: density of oil at 288K;

[0043] Calculated to get L c is the Ostwald coefficient at temperature T, so the dissolved gas concentration in the final formulated oil is:

[0044]

[0045] ω g : the gas concentration (%) passed into the oil;

[0046] Q g / o : the actual flow rate of ...

Embodiment 2

[0071] The purpose of Example 2 is to prepare transformer oils with dissolved gas concentrations in No. 10 transformer oil of 350 ppm, 480 ppm and 640 ppm under the condition of 80°C.

[0072] The specific operation process of this embodiment 2 is the same as that of embodiment 1.

[0073] The final calculation shows that when the dissolved gas concentrations in the transformer oil are 350ppm, 480ppm and 640ppm respectively, the flow control ratios in the oil-gas dissolution chamber and the transformer oil control greenhouse are respectively and

Embodiment 3

[0075] The purpose of Example 3 is to prepare transformer oils with dissolved gas concentrations of 50 ppm and 200 ppm in No. 25 and No. 45 transformer oils under the condition of 80° C., respectively.

[0076] The specific operation process of this embodiment 3 is the same as that of embodiment 1.

[0077] Finally, the flow control ratios in the oil-gas dissolution chamber and transformer oil control greenhouse of No. 25 transformer oil and No. 45 transformer oil are calculated as and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com