One-box two-casting casting technology of marine diesel engine cylinder cover casting

A technology of marine diesel engine and casting process, which is applied in the direction of manufacturing tools, casting molding equipment, molding boxes, etc., can solve the problems of large investment in tooling costs, sand mold costs, etc. effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

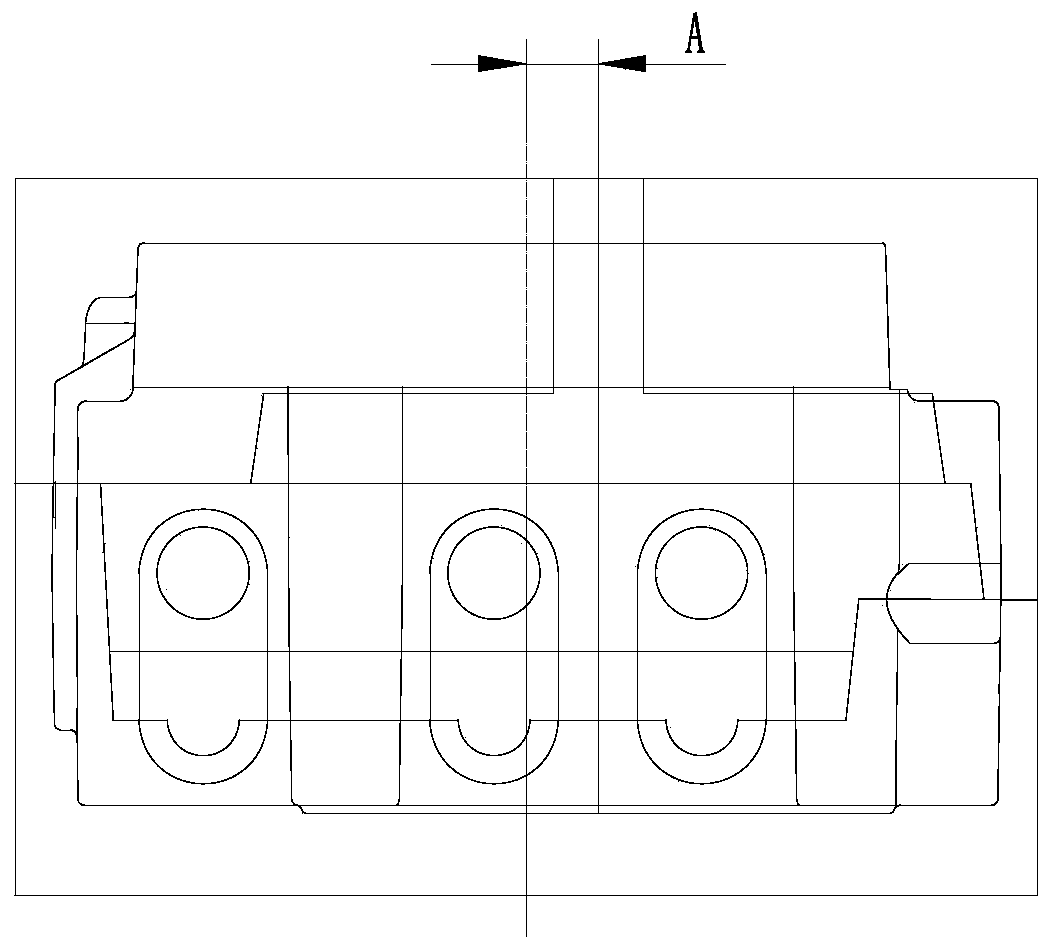

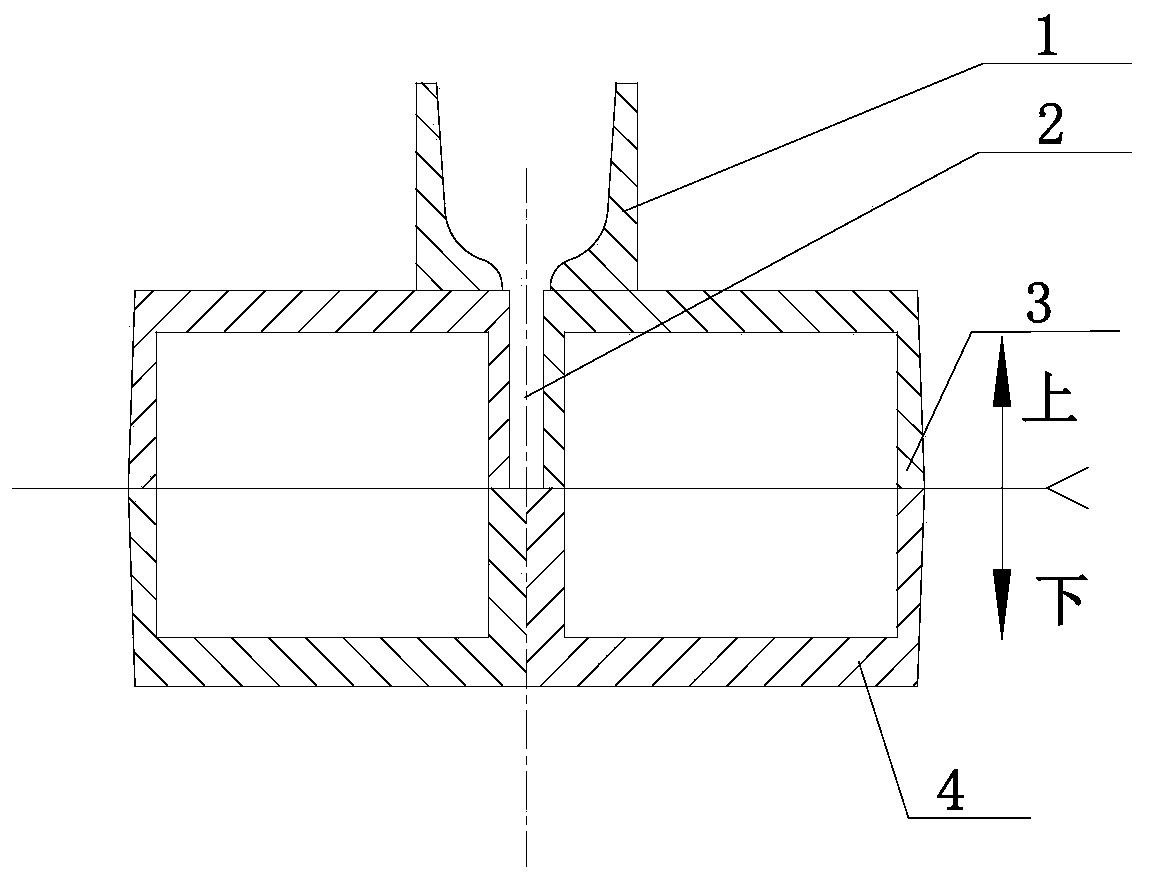

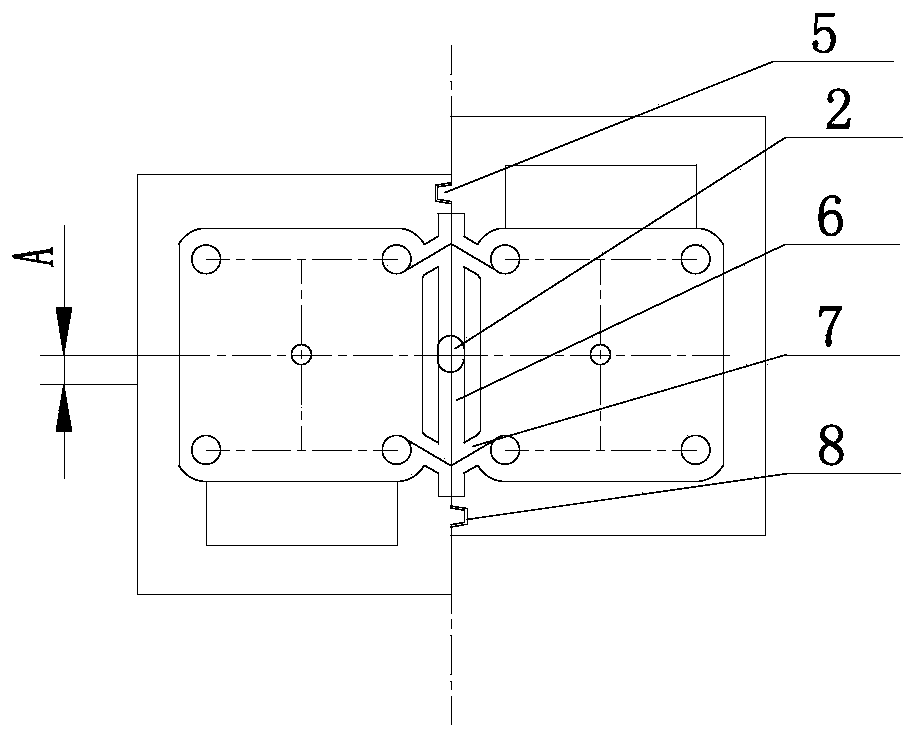

[0032] Such as Figure 1 to Figure 7 As shown, the casting process of one box of two pieces of marine diesel engine cylinder head castings according to the present invention is characterized in that the following steps are taken:

[0033] ①Design the casting process. According to the structure of the cylinder head casting, the gating system is determined to be the middle injection, and the parting surface of the sand mold of the outer mold of the casting is reasonably designed. See the attached figure 1 And attached figure 2 . In order to reduce the amount of coated sand and reduce production costs, the basic thickness of the outer mold sand mold is determined to be controlled at 15mm, and reinforcement ribs are added to ensure the strength of the sand mold.

[0034] ②Determine that the arrangement of the left and right cylinder head sand molds is center-symmetrical, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com