Special saw blade for cutting outer water retaining part and bright strip of automobile

A technology of external water blocking and saw blades, which is applied to metal sawing equipment, knives of sawing machine devices, metal processing equipment, etc., can solve the problems of high cutting noise, reduced production efficiency, and rough cutting section, so as to reduce cutting noise , improve the service life and save cutting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

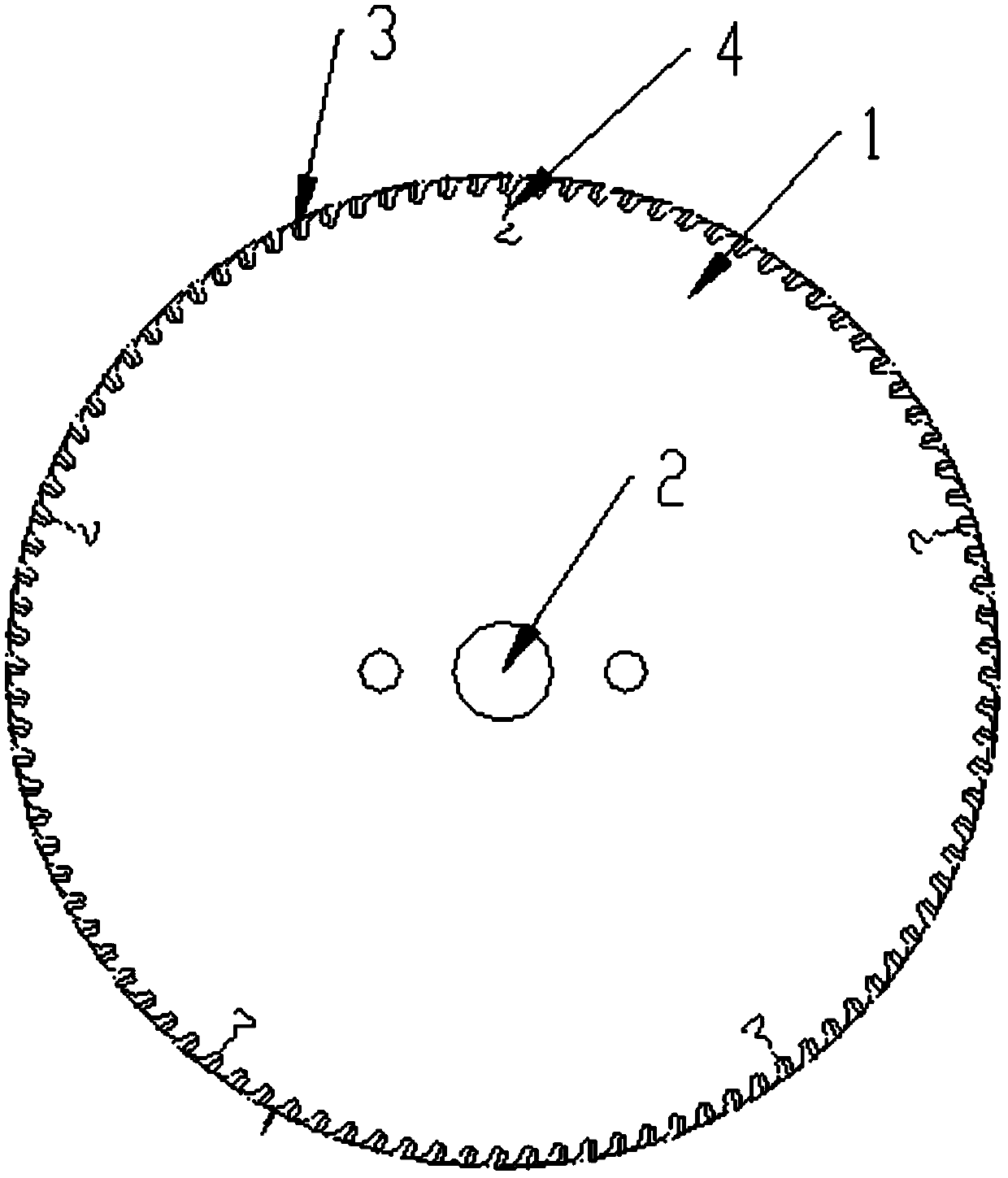

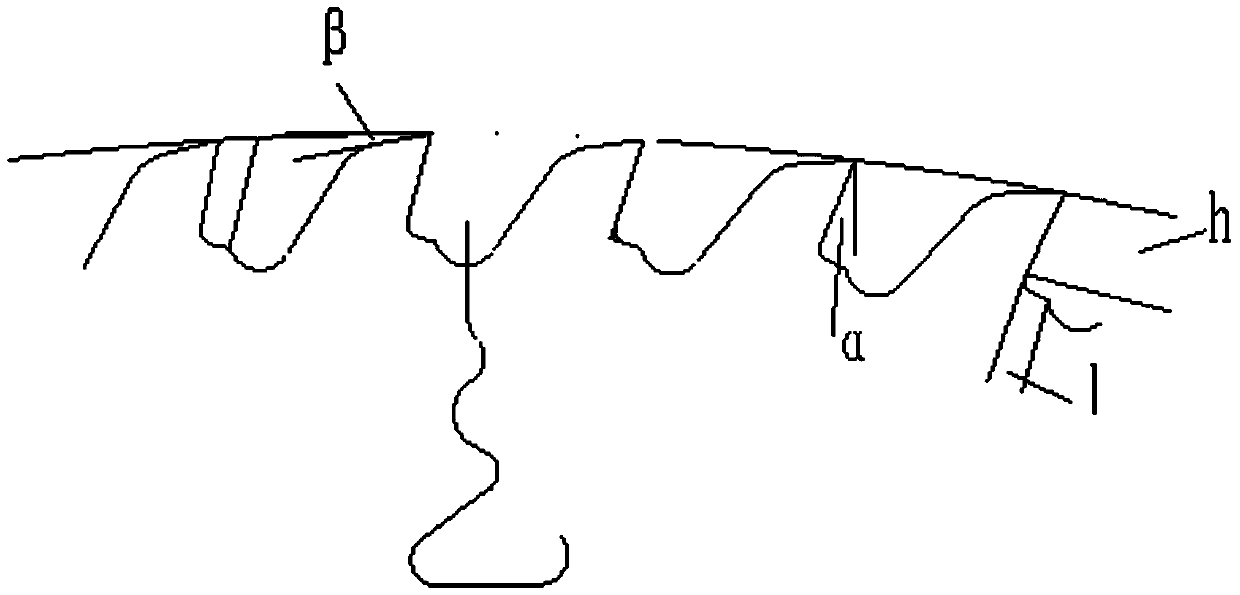

[0023] like Figure 1 to Figure 3 As shown in the figure, a special saw blade for cutting automobile exterior water barriers and bright strips includes a circular saw blade 1. The circular saw blade 1 is a circular saw blade made of cermet, and the cermet is based on alumina. It is compounded with metal tungsten, the thickness of the circular saw blade 1 is 1.3mm, the diameter of the circular saw blade 1 is 200mm, the saw blade is concave from the outside to the middle and then to the circle, and the concave angle is 0°-0.5° , the centripetal angle is 0°-5°, the concave structure makes the saw blade more flexible, the circular saw blade 1 is machined with a concentric circular hole 2 in the center, the diameter of the concentric circular hole 2 is 25mm, and the circular saw blade 1 is processed on the There is a muffler wire with a diameter of 0.2mm, the muffler wire is made of damping glue, the circular saw blade 1 is welded with a high-frequency welding machine using a metal...

Embodiment 2

[0025] like Figure 1 to Figure 3 As shown in the figure, a special saw blade for cutting automobile exterior water barriers and bright strips includes a circular saw blade 1. The circular saw blade 1 is a circular saw blade made of cermet, and the cermet is based on alumina. It is compounded with metal tungsten. The thickness of the circular saw blade 1 is 1.4mm, the diameter of the circular saw blade 1 is 255mm, the saw blade is concave from the outside to the middle and then to the circle, and the concave angle is 0°-0.5° , the centripetal angle is 0°-5°, the concave structure makes the saw blade more flexible, the circular saw blade 1 is machined with a concentric circular hole 2 in the center, and the diameter of the concentric circular hole 2 is 25.4mm. A muffler wire with a diameter of 0.3mm is processed. The muffler wire is made of damping glue. The circular saw blade 1 is welded with a high-frequency welding machine using a metal ceramic. The number of saw blade heads...

Embodiment 3

[0027] like Figure 1 to Figure 3 As shown in the figure, a special saw blade for cutting automobile exterior water barriers and bright strips includes a circular saw blade 1. The circular saw blade 1 is a circular saw blade made of cermet, and the cermet is based on alumina. It is compounded with metal tungsten, the thickness of the circular saw blade 1 is 1.6mm, the diameter of the circular saw blade 1 is 255mm, the saw blade is concave from the outside to the middle and then to the circle, and the concave angle is 0°-0.5° , the centripetal angle is 0°-5°, the concave structure makes the saw blade more flexible, the circular saw blade 1 is machined with a concentric circular hole 2 in the center, and the diameter of the concentric circular hole 2 is 25.4mm. A muffler wire with a diameter of 0.3mm is processed. The muffler wire is made of damping glue. The circular saw blade 1 is welded with a high-frequency welding machine using a metal ceramic. The number of saw blade heads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com