Anti-splashing ceramic tile cutting platform capable of achieving rapid positioning and cutting technology of anti-splashing ceramic tile cutting platform

A cutting platform and anti-splash technology, which is applied in the field of cutting tools, can solve the problems of tile slag splashing, harming staff, affecting cost and quality, and affecting cutting efficiency, so as to increase accuracy and positioning efficiency, improve cutting efficiency, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

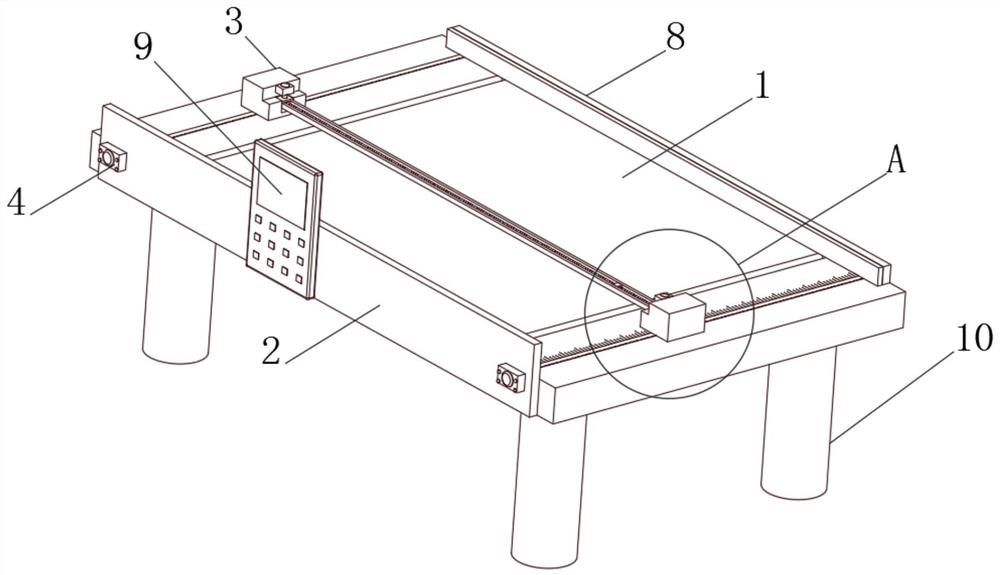

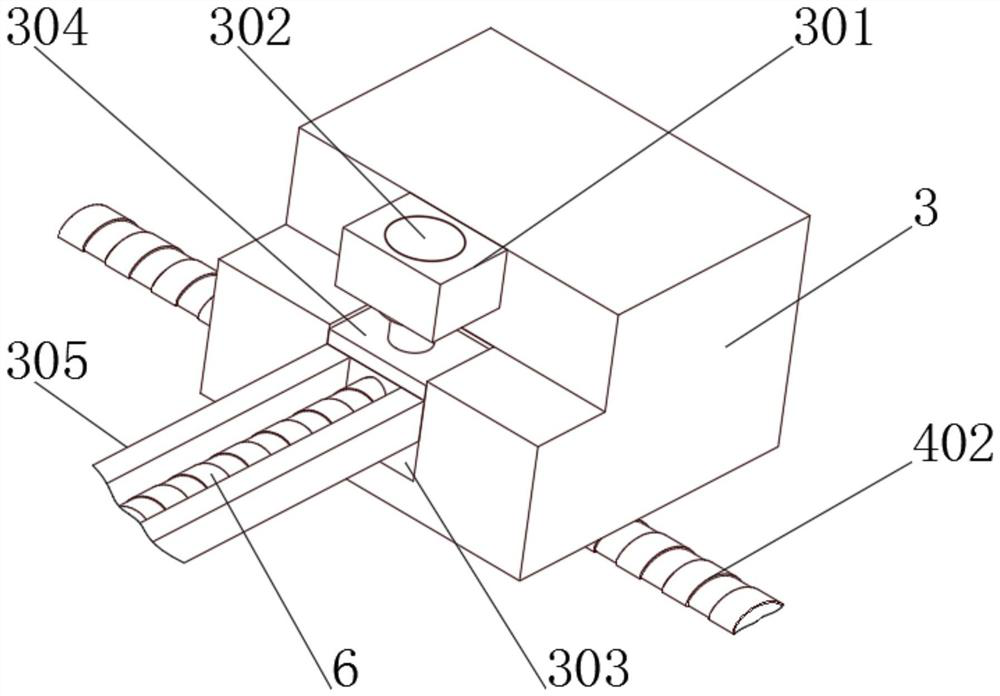

[0039] see Figure 1-5, the present invention provides a technical solution: a quickly positioned anti-splash ceramic tile cutting platform, including a main body 1 and a baffle plate 2, a first chute 101 is opened on the top outer wall of the main body 1, and the inner wall of the first chute 101 slides The first sliding seat 3 is connected, the outer wall of the first sliding seat 3 is fixedly connected with the first installation platform 301, the inner wall of the first installation platform 301 is fixedly connected with the first hydraulic rod 302, and the first hydraulic rod 302 is far away from the first installation platform One end of 301 is fixedly connected with a first slide plate 304, and the outer wall of the first installation platform 301 is provided with a first groove 303, and the inner wall of the first groove 303 is slidingly connected with the outer wall of the first slide plate 304, and one side of the first slide plate 304 The outer wall is fixedly conne...

Embodiment 2

[0042] see Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top outer wall of the main body 1 is provided with a third chute 103, and the inner wall of the third chute 103 is slidably connected with the second sliding seat 5, and the second One side of the outer wall of the slide seat 5 is fixedly connected with a second installation platform 501, and the inner wall of the second installation platform 501 is fixedly connected with a second hydraulic rod 502, and one end of the second hydraulic rod 502 away from the second installation platform 501 is fixedly connected with a second Sliding plate 504, the outer wall of the second mounting platform 501 is provided with a second groove 503, the inner wall of the second groove 503 is slidingly connected with the outer wall of the second sliding plate 504, and the inner wall of the second sliding plate 504 is fixedly connected with the second motor 505. The output shaft of...

Embodiment 3

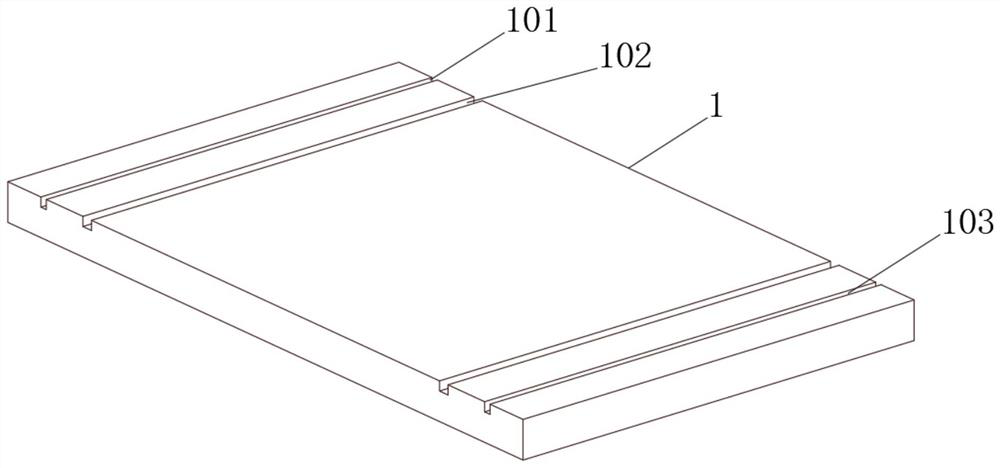

[0045] see Figure 1-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a kind of technical scheme: the outer wall of the third screw mandrel 6 is threadedly connected with knife seat 7, and the outer walls of both sides of knife seat 7 are all connected with the outer wall of track 305 Sliding connection, the bottom outer wall of the knife seat 7 is fixedly connected with a knife head 701, the outer wall of the main body 1 is provided with a second chute 102, the top outer wall of the main body 1 is provided with a push plate 8, and one side of the outer wall of the push plate 8 is fixedly connected with a rubber Gasket 801, the bottom outer wall of push plate 8 is fixedly connected with slider 802, the outer wall of slider 802 is fixedly connected with the inner wall of second chute 102, the outer wall of push plate 8 and the outer wall of main body 1 pass through the second chute provided 102 and slider 802 are slidably connected.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com