Portable pipe welding robot

A welding robot and portable technology, applied in welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of difficult to meet the round pipe welding, the welding efficiency cannot be effectively improved, and the quality is unstable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical features of the solution can be clearly described, and the solution will be described through specific implementation modes below.

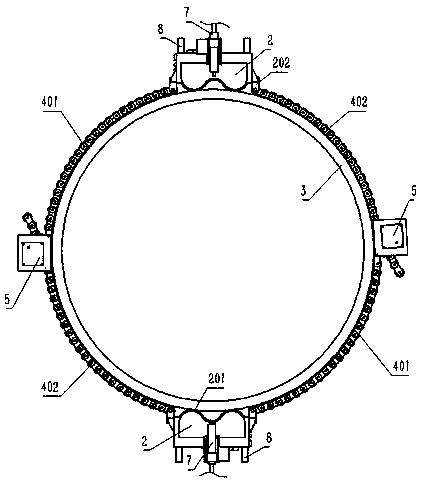

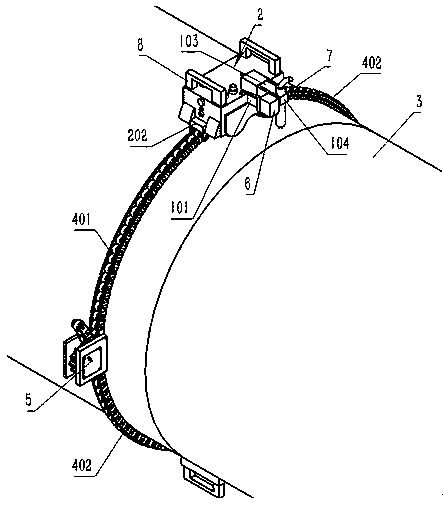

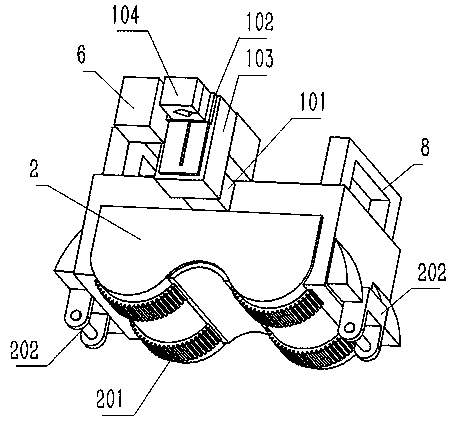

[0030] see Figure 1 to Figure 5 As shown, the present embodiment is a portable pipe welding robot, which includes a welding assembly, and also includes a car body 2 arranged on the periphery of a metal round pipe 3 that is to be welded in a building environment and can be adsorbed by a magnet. The car body 2 is provided with two one, symmetrically arranged on the outside of the round pipe 3, the bottom of each car body 2 is provided with four rollers 201, the rollers 201 are attached to the outer surface of the round pipe 3; the rollers 201 are permanent magnetic wheels with adsorption, each The rollers 201 are all magnetically connected with the round pipe 3, and the periphery of the rollers 201 is gear-shaped, and gear teeth are arranged on the wheel surface in contact with the outer wall of the round pipe 3, and the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com