Socket assembling equipment and socket assembling method

An assembly equipment and assembly device technology, which is applied in the field of automation, can solve the problems of high competition pressure in the product market, inconformity with the structural characteristics of sockets, and high difficulty in socket assembly, achieving high assembly efficiency, realizing production with fewer people, and occupying a small area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The following is attached Figures 1 to 20 The given examples further illustrate the specific implementation of the socket assembly device created by the present invention. The socket fitting device created by the present invention is not limited to the description of the following embodiments.

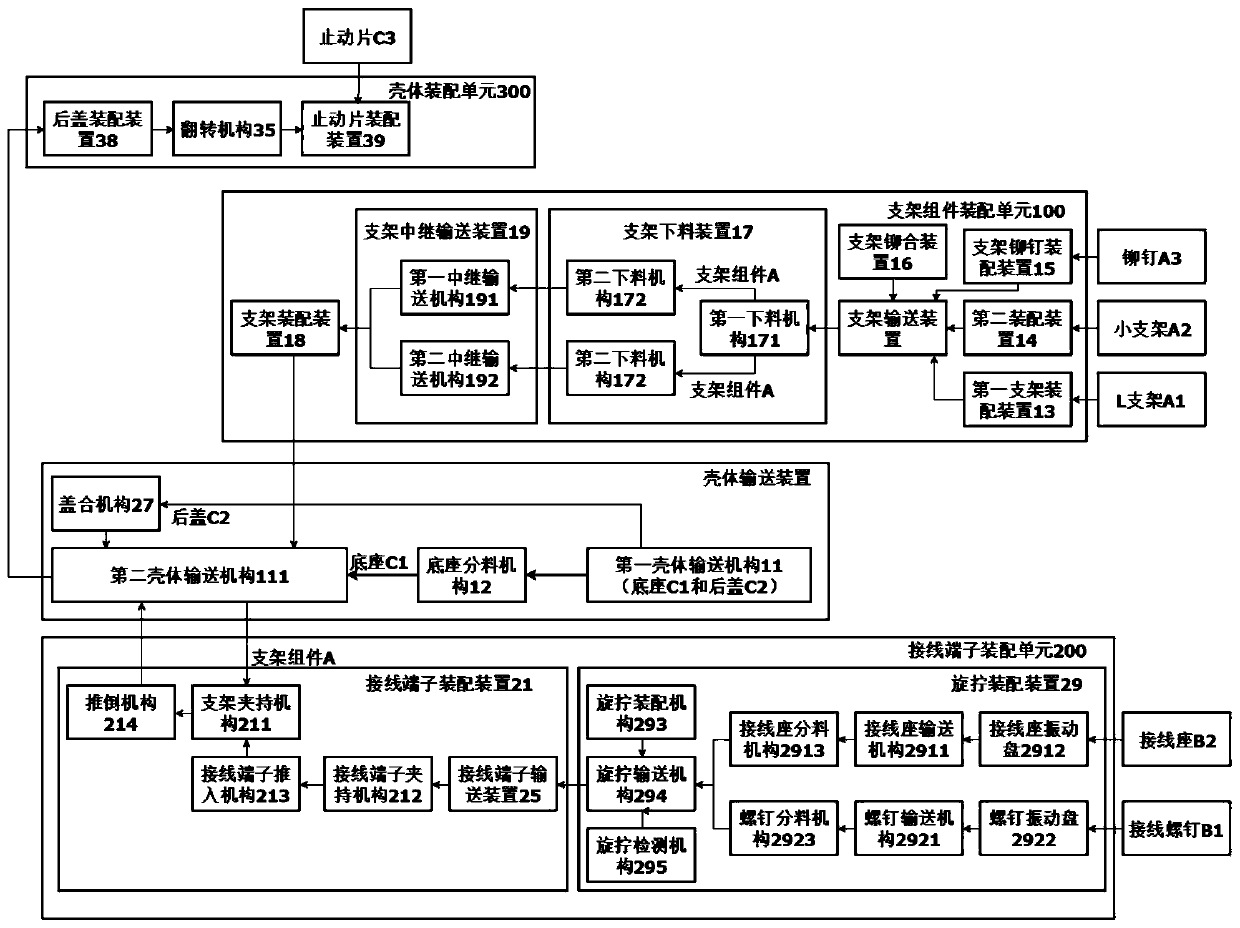

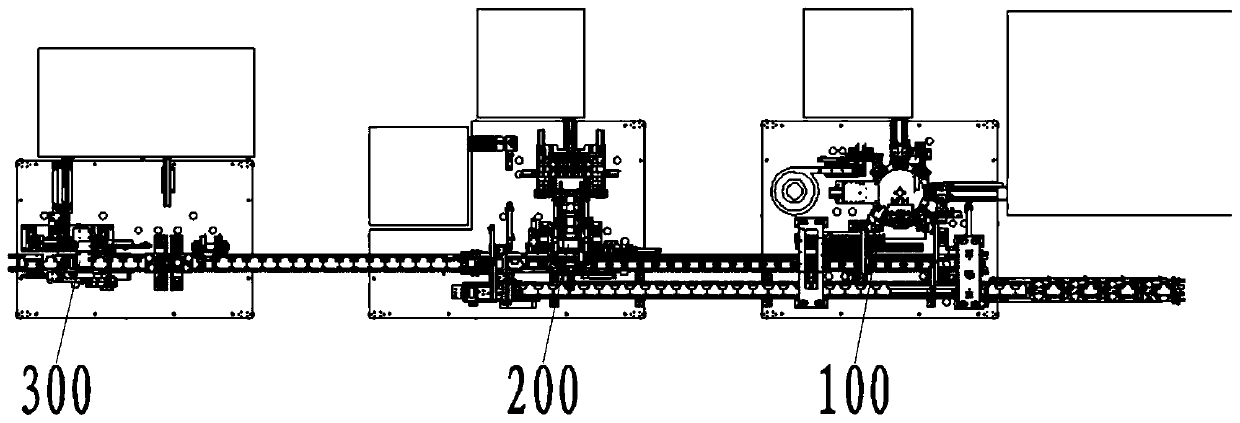

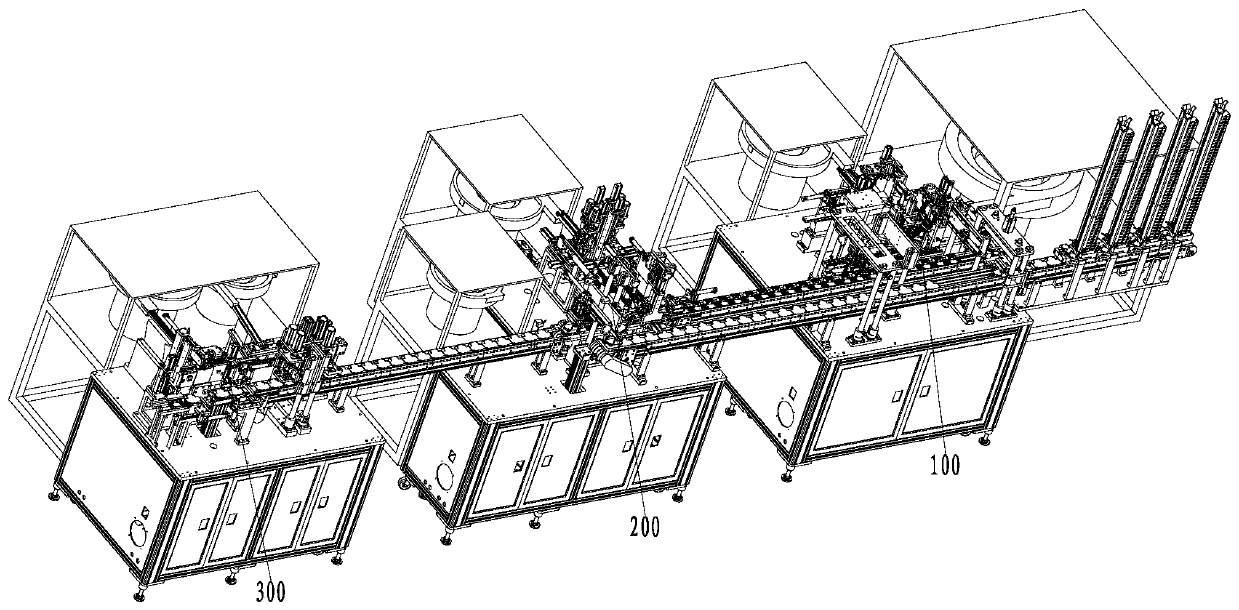

[0074] Such as Figure 1-3 As shown, the socket assembly equipment created by the present invention includes a shell conveying device for conveying socket shells, and a bracket assembly assembly unit 100, a terminal assembly unit 200 and a shell assembly unit 300 arranged in sequence along the shell conveying device, The bracket component assembly unit 100 first assembles the bracket component A, then installs the bracket component A into the base C1 of the socket housing, and finally sends the socket housing to the terminal assembly unit 200;

[0075] The terminal assembly unit 200 first assembles the terminal B, then installs the terminal B into the base C1 of the socket ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com