CNC press

A technology of presses and indenters, applied in the field of presses, can solve the problems of low press-fitting efficiency and long stroke of the push rod of the press, and achieve the effects of improving press-fitting efficiency, good versatility, and easy layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

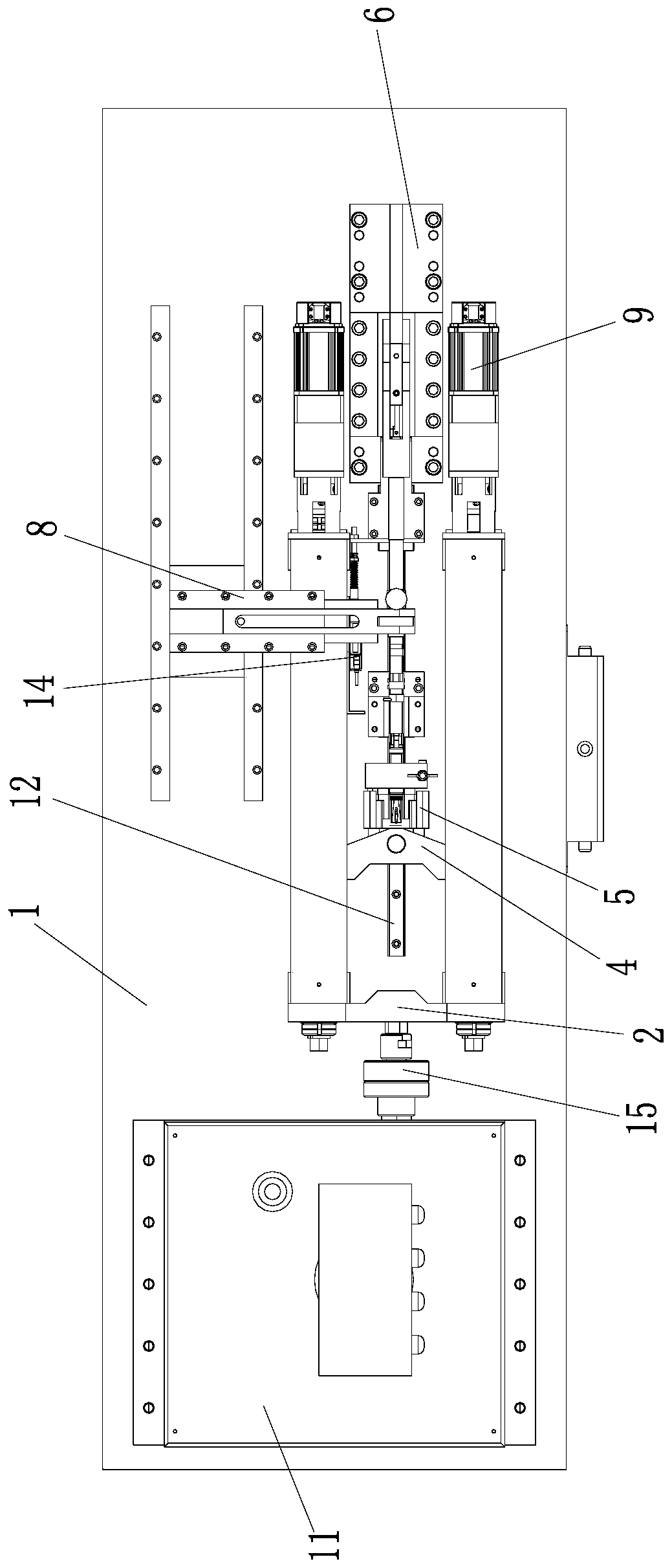

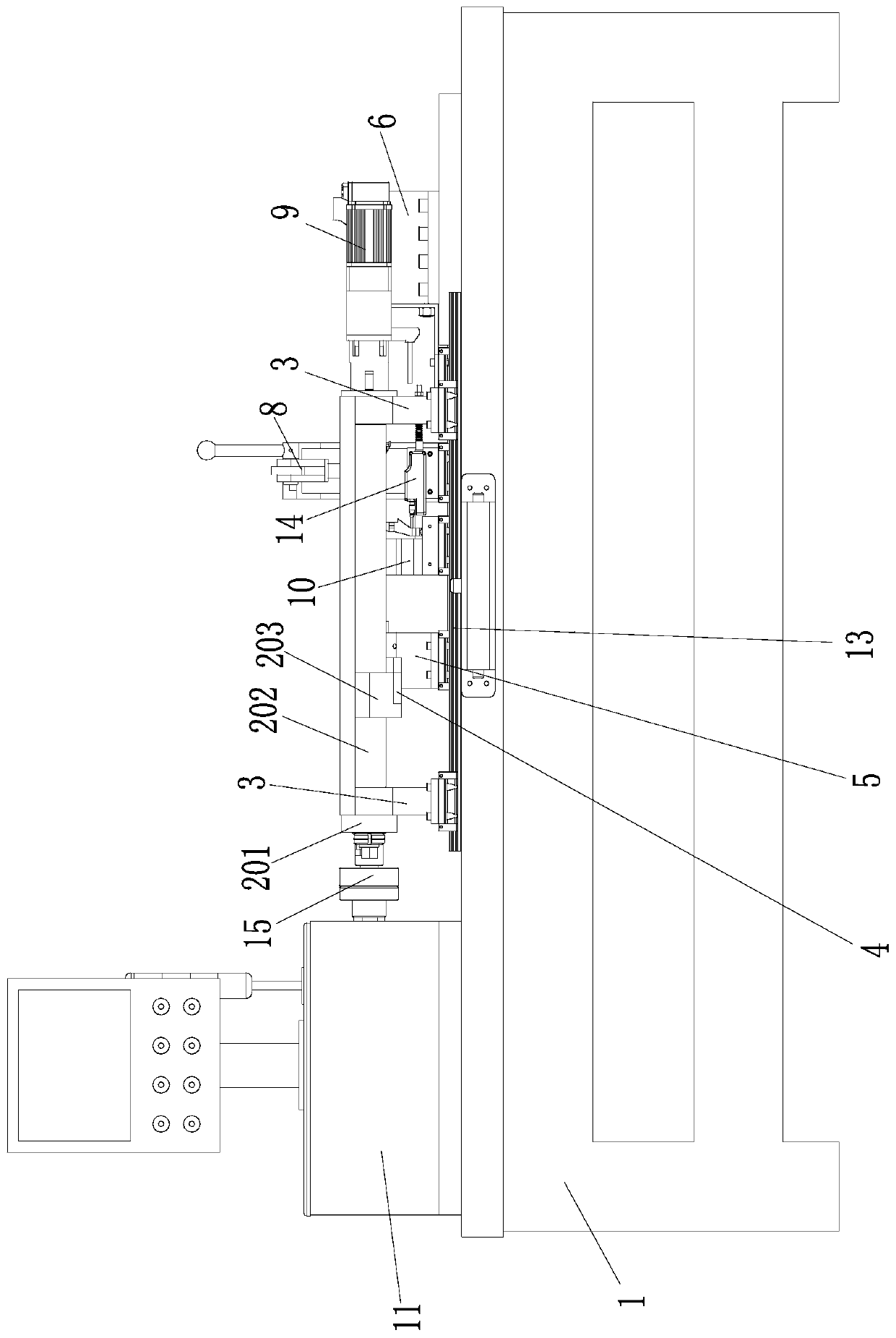

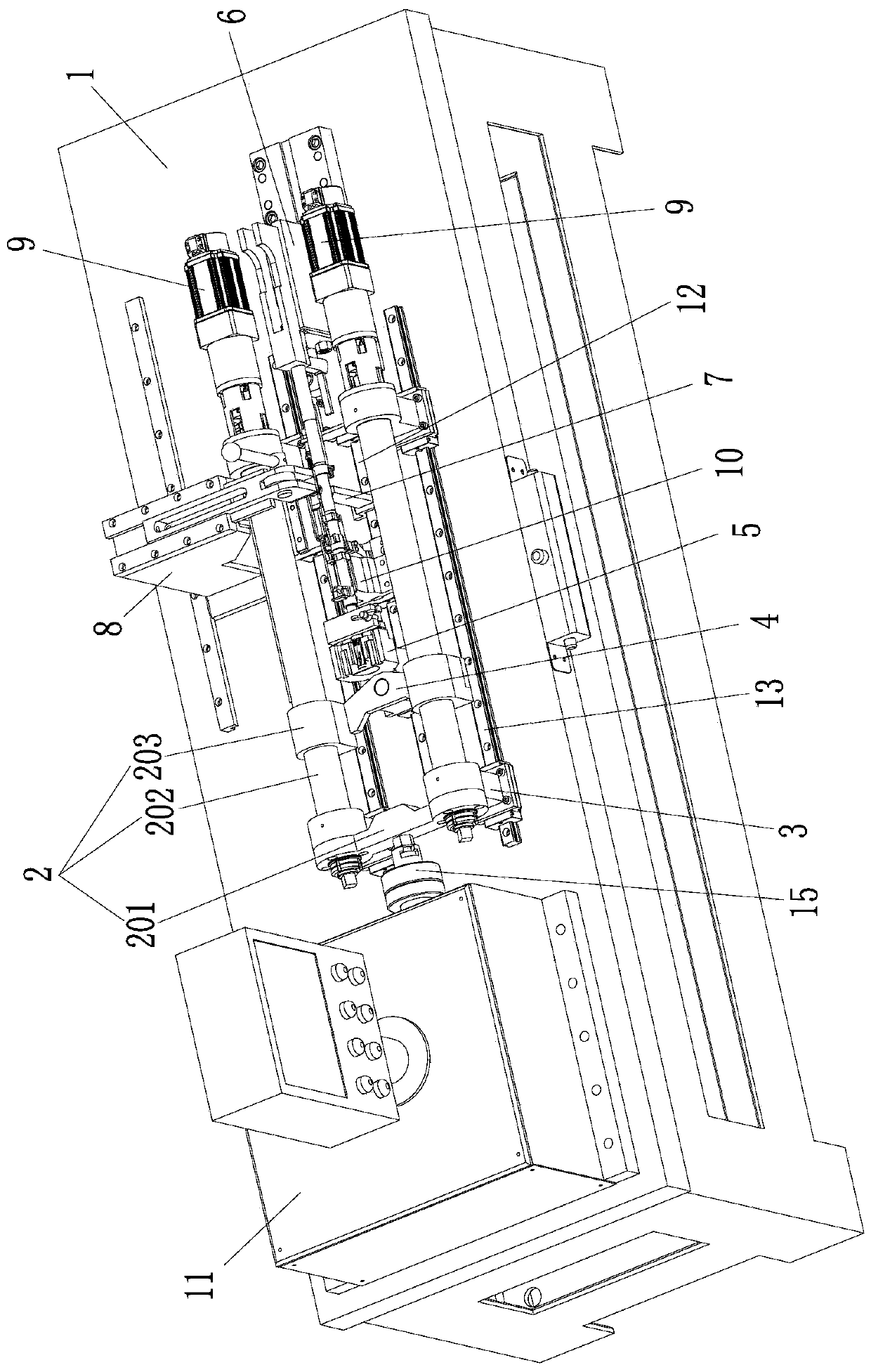

[0022] Such as Figure 1 to Figure 3 As shown, a numerical control press is mainly composed of a workbench 1, a servo electric cylinder 11, an intermediate slide rail 12, two screw rod slide rails 13, a barrel positioning device and a press-fitting mechanism. The workbench 1 consists of a frame and The table is composed of welded parts of section steel, and the table is a rectangular steel casting with good rigidity. The table is installed on the frame by bolts. The upper surface is finely ground and has high flatness. The servo electric cylinder 11 passes through the servo electric cylinder mounting seat. Installed on the table top of the workbench 1, its push rod is facing right, the display and the three-color indicator light of the press control system are installed on the servo electric cylinder mounting seat, the middle slide rail 12, two screw mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com