Reverse pressing system of nail shooting pill

A nail-shooting and reverse technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to shoot nails and apply pressure, and achieve the effects of avoiding errors, improving production efficiency, and smoothing the press-fitting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

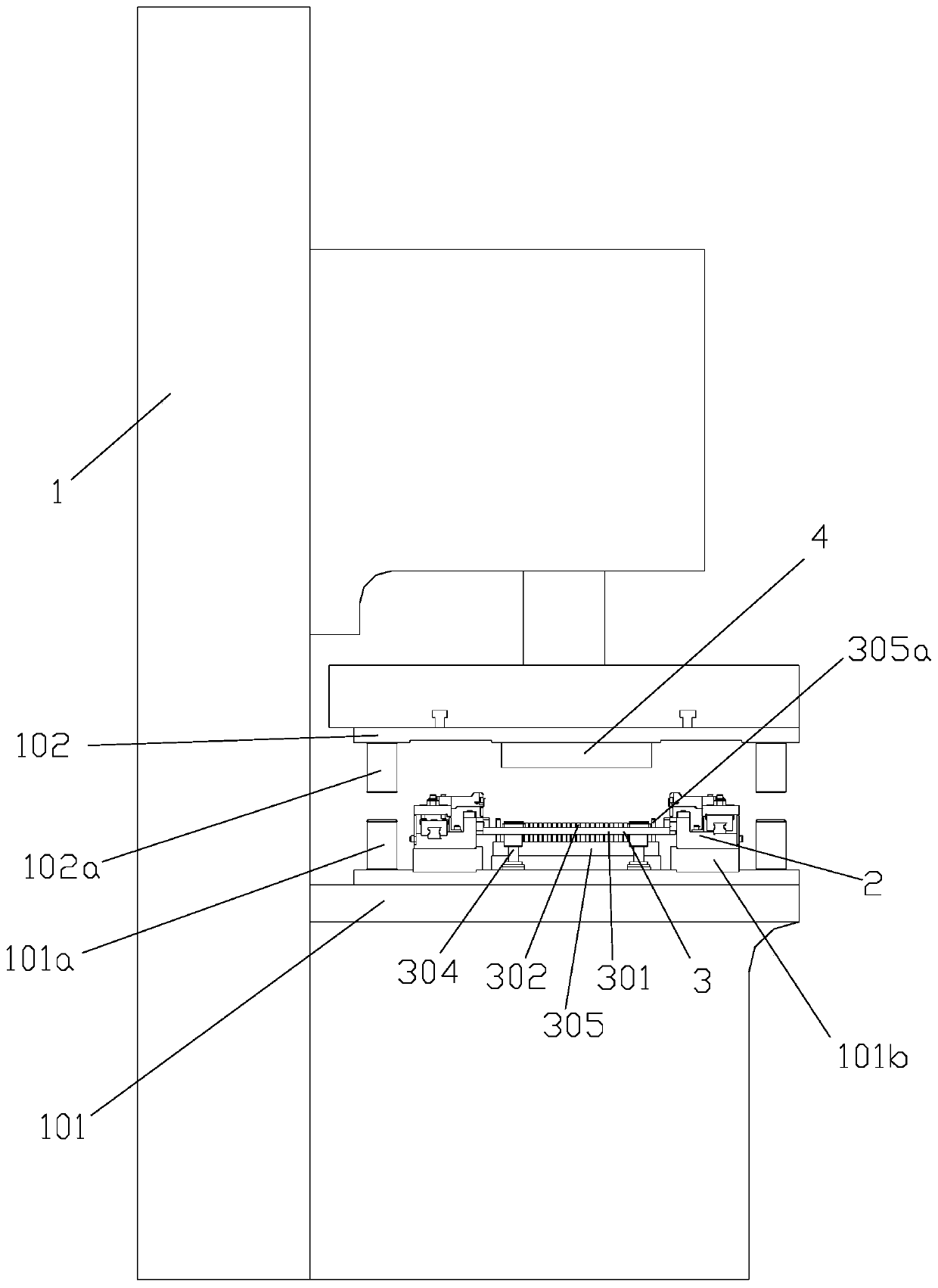

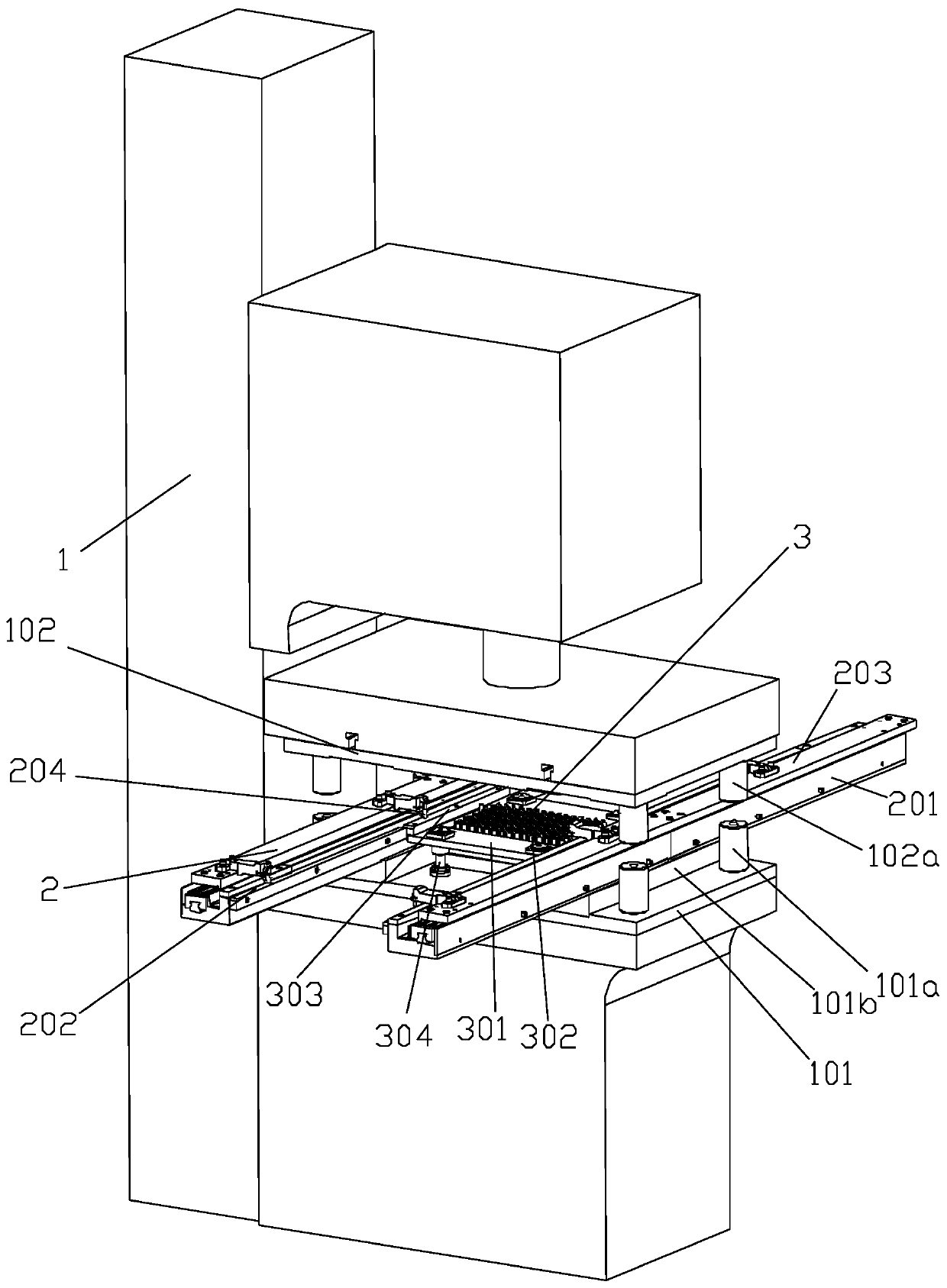

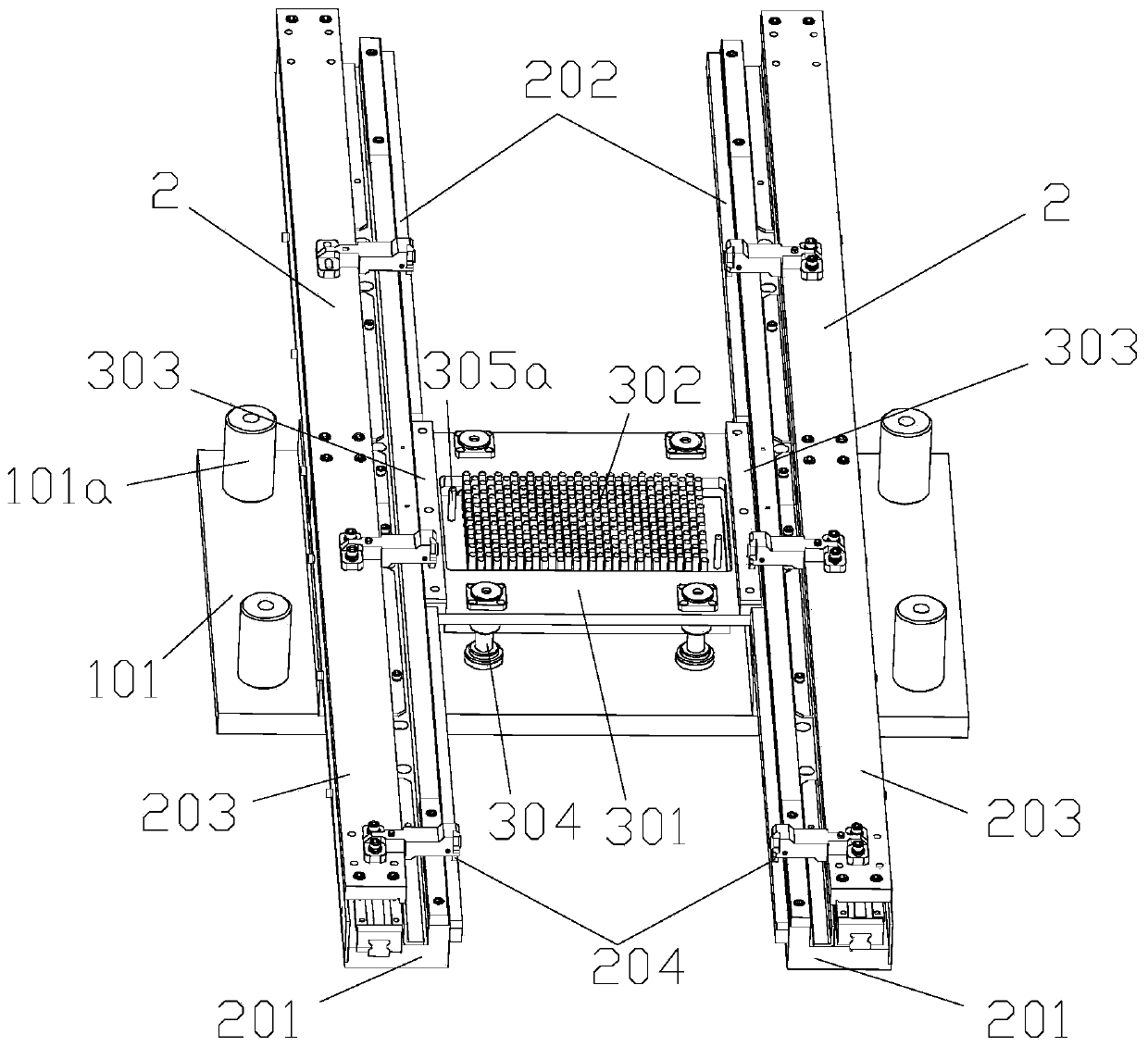

[0022] Such as Figure 1 to Figure 5 As shown, a reverse pressing system for nail shooting bullets is mainly composed of a press 1, a floating pressing mechanism 3, a horizontal upper pressing plate 4 and a conveying mechanism 2, and the floating pressing mechanism 3 is set on the working table of the pressing machine 1 , the horizontal platen 4 is connected with the pressure head of the press 1, and is located directly above the floating pressing mechanism 3, the conveying mechanism 2 passes between the working table of the press 1 and the pressure head, and the conveying mechanism 2 is used to convey the upper and lower The nail-shooting projectile loading plate 5 and the cartridge loading plate 6 stacked together.

[0023] Such as Figure 1 to Figure 5 As shown, a lower mounting plate 101 is fixed on the working table of the press 1, and the floating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com