Double-component wood super-hydrophobic modification liquid taking ethanol as dispersing agent

A super-hydrophobic modification, two-component technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of high cost of modifiers, high toxicity of dispersants, etc., and achieve the effect of easy construction and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

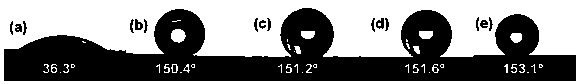

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 35 g of absolute ethanol, 1.5 g of hydrogen-containing silicone oil, 1.2 g of white carbon black, and 0.008 g of ethynyl cyclohexanol into the container, and after ultrasonic dispersion is uniform, modified liquid A is obtained. Add 35 g of absolute ethanol, 0.8 g of white carbon black, and 0.05 g of catalyst into another container, and after ultrasonic dispersion is uniform, the modified solution B is obtained.

[0020] (2) Take a plastic wide-mouth container (such as a beaker), add 15 g of modified solution A and 30 g of modified solution B, and mix well.

[0021] (3) Surface hydrophobic modification of wood: immerse the wood block in the modification solution for 3 min.

[0022] (4) Drying of modified wood blocks: Place the soaked wood blocks in step (3) at 50°C for 120 min to dry.

Embodiment 2

[0024] (1) Add 50 g of absolute ethanol, 3 g of hydrogen-containing silicone oil, 2 g of white carbon black, and 0.2 g of tetravinyltetramethylcyclotetrasiloxane into the container, and disperse evenly by ultrasonic to obtain modified liquid A. Add 50 g of absolute ethanol, 2.2 g of white carbon black, and 0.1 g of catalyst into another container, and obtain the modified solution B after ultrasonic dispersion.

[0025] (2) Take a plastic wide-mouth container (such as a beaker), add 50 g of modified solution A and 50 g of modified solution B, and mix well.

[0026] (3) Surface hydrophobic modification of wood: immerse the wood block in the modification solution for 10 min.

[0027] (4) Drying of modified wood blocks: Place the soaked wood blocks in step (3) at 90°C for 60 min to dry.

Embodiment 3

[0029] (1) Add 60 g of absolute ethanol, 7 g of hydrogen-containing silicone oil, 3 g of white carbon black, and 0.03 g of ethynyl cyclohexanol into the container, and after ultrasonic dispersion is uniform, modified liquid A is obtained. Add 60 g of absolute ethanol, 3.5 g of white carbon black, and 0.15 g of catalyst into another container, and after ultrasonic dispersion is uniform, modified liquid B is obtained.

[0030] (2) Take a plastic wide-mouth container (such as a beaker), add 60 g of modified solution A and 30 g of modified solution B, and mix well.

[0031] (3) Hydrophobic modification of the wood surface: the wood block was immersed in the modification solution for 15 min.

[0032] (4) Drying of modified wood blocks: Place the soaked wood blocks in step (3) at 120°C for 30 min to dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com