Energy-saving consumption-reducing mould temperature controller

A technology of mold temperature machine and main box, which is applied in the field of mechanical equipment, can solve the problems of inconvenient movement, high energy consumption, single heat dissipation mode of mold temperature machine, etc., and achieve the effect of increasing convenience and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

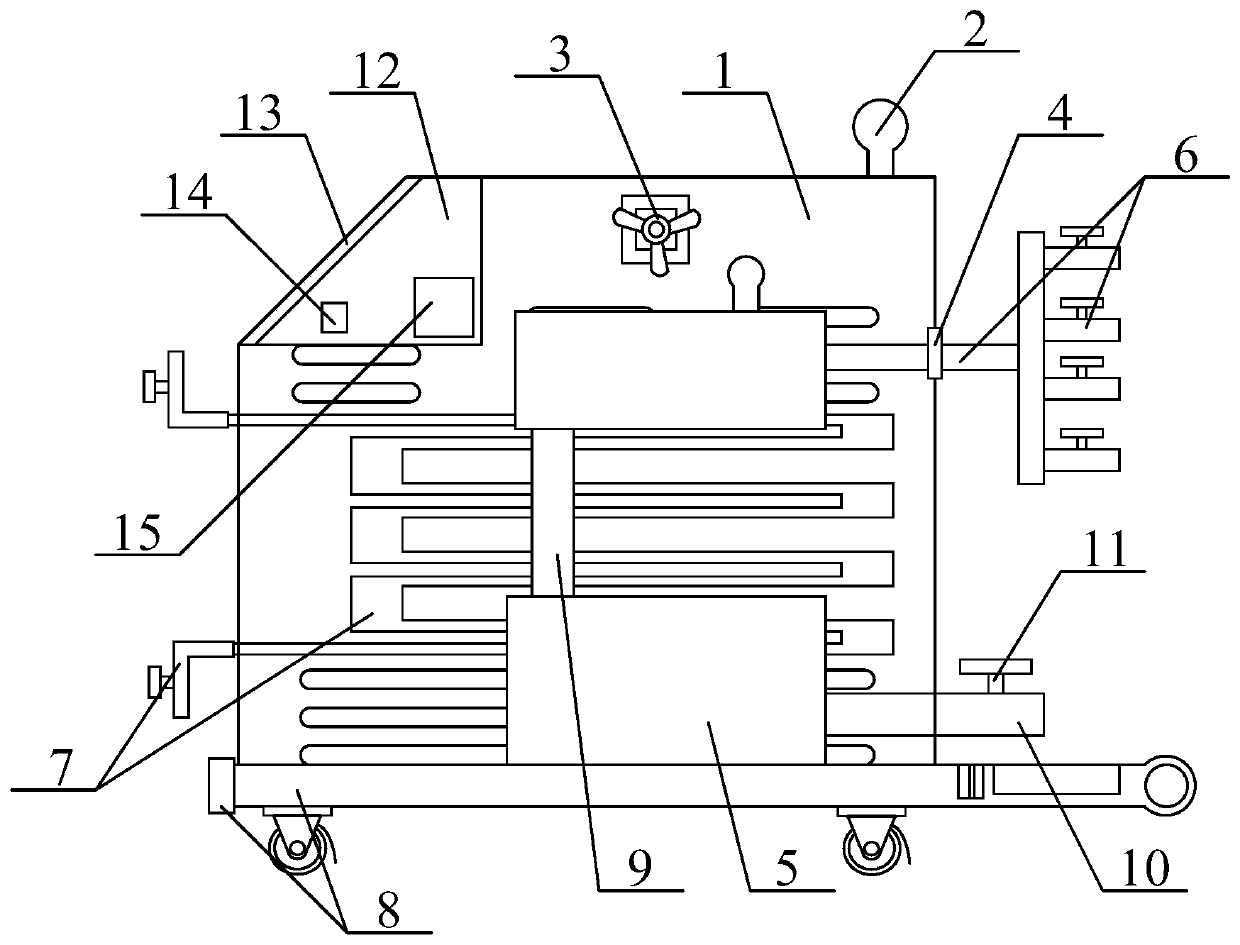

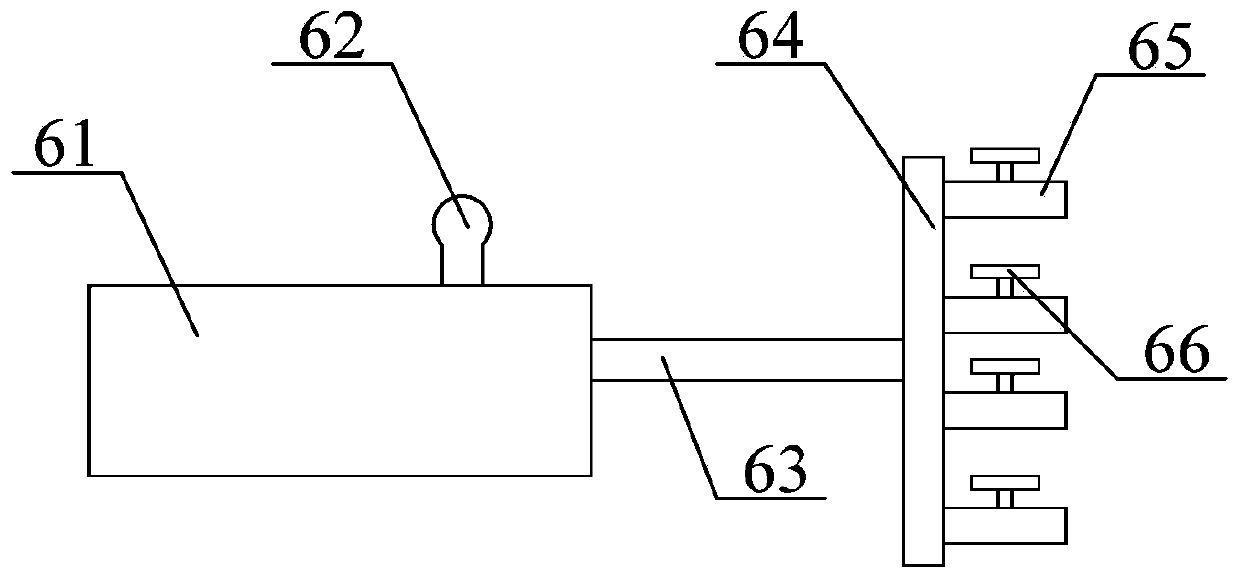

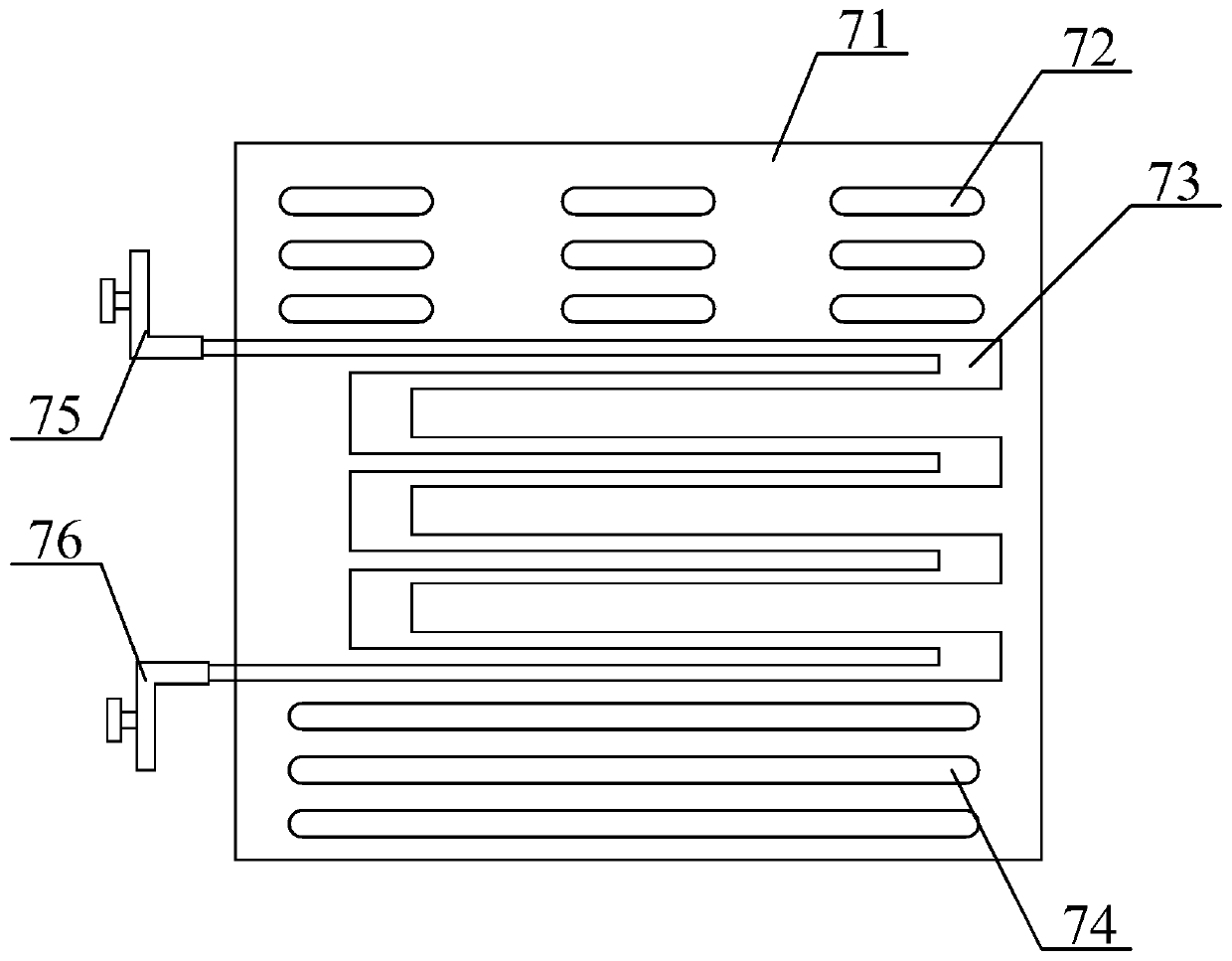

[0037] as attached figure 1 to attach figure 2 As shown, the present invention provides an energy-saving and consumption-reducing mold temperature machine, including a mold temperature machine main box 1, an over-temperature alarm 2, a cooling fan 3, a sealing ring gasket 4, a circulation pump 5, and a temperature-measuring buffer diversion box Structure 6, cooling plate structure 7 that can add coolant, mobile tray structure that can fix the oil leakage box 8, heat pipe 9, oil inlet pipe 10, oil inlet control valve 11, control box 12, touch control panel 13, main power switch 14 and an energy-saving control host 15, the mold temperature machine main box 1 is installed on the upper part of the mobile tray structure 8 that can fix the oil leakage box; the over-temperature alarm 2 is threadedly connected to the mold temperature machine main box 1 on the right side of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com