3c Manufacturing method of curved shell for electronic device

The technology of an electronic device and manufacturing method, which is applied in the field of shell manufacturing, can solve the problems of long production time, waste of cost, difficulty in achieving smooth and wrinkle-free finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is to make use of technology content, the effectiveness of the invention and its purpose is to reach a more complete and clear expose, now at the detailed description, and please also refer to the uncovering of plans and drawings:

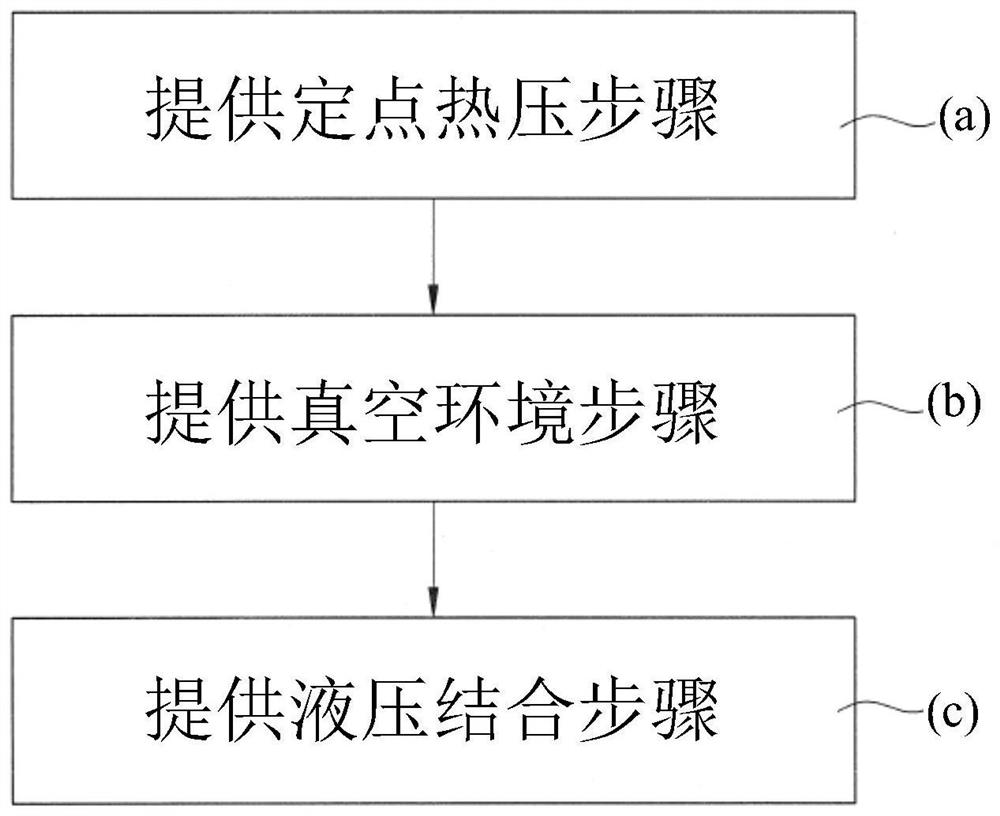

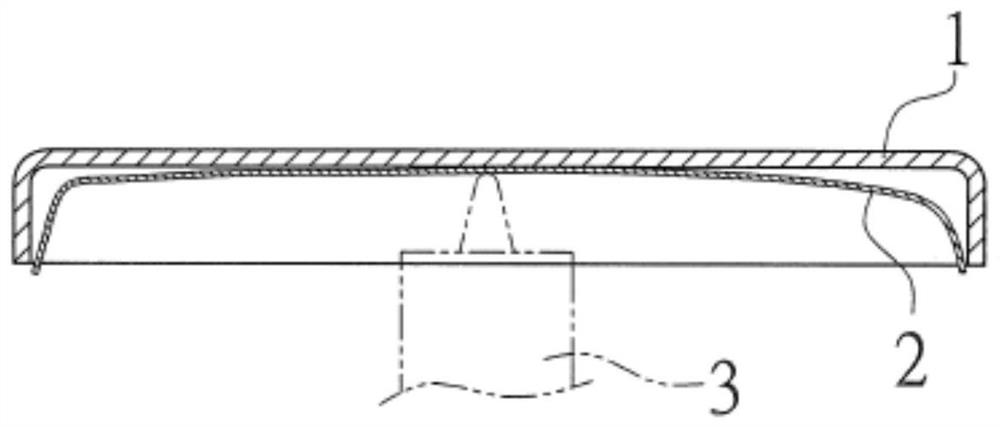

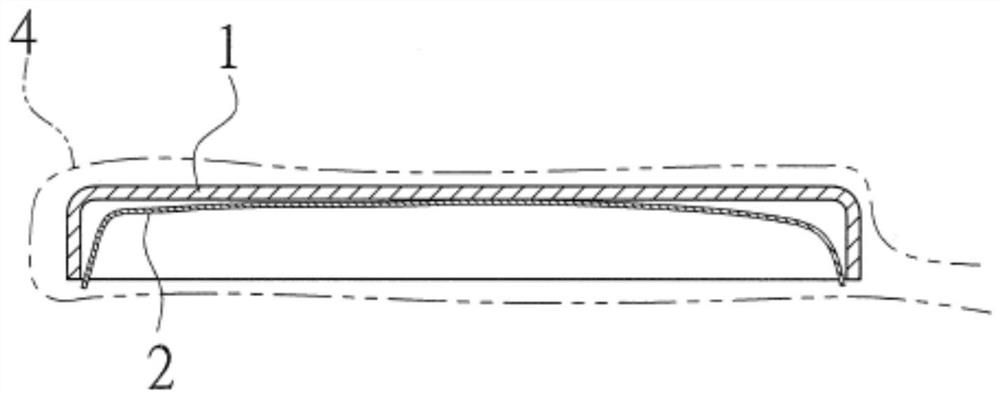

[0029] First, please see Figure 1 ~ 4 , The steps of the method of manufacturing a housing surface 3C of the electronic device of the present invention and a schematic cross-sectional view, which comprises the steps of:

[0030] (A) providing a pointing pressing step, curved arc having a light-transmitting base shell design features a decorative film 2, using the thermal head 3 and the decorative film 2 is subjected to hot point, and positioned in the bonded the transparent substrate 1 case;

[0031] (B) the step of providing a vacuum environment, the point bonding said decorative shell of the light-transmissive film 2 is placed in a vacuum bag 4, and the vacuum is drawn, the decorative film 2 and the transparent substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com