Desulfurization device for petroleum smelting and operation method of device

A desulfurization device, petroleum smelting technology, applied in the direction of only multi-stage series refining process treatment, etc., can solve the problems of unsafe use, poor effect, complex structure, etc., and achieve the effect of strengthening desulfurization, improving desulfurization effect and desulfurization effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

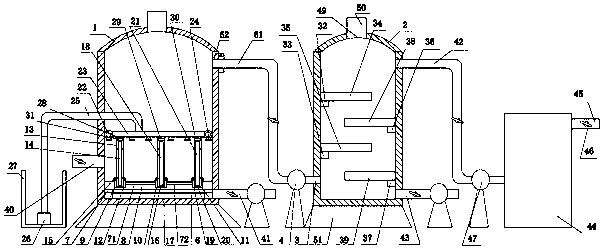

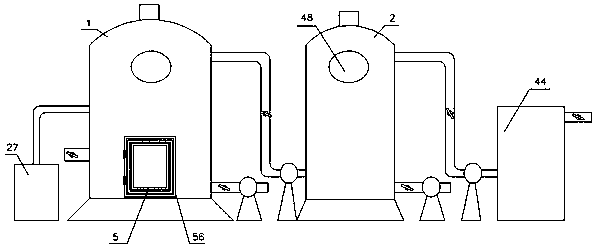

[0029] A petroleum smelting desulfurization device, which consists of: a No. 1 desulfurization tank 1 and a No. 2 desulfurization tank 2. The front side of the No. 1 desulfurization tank is provided with an inlet 5, and an ultrasonic generator is loaded along the inlet. 6, the No. 1 desulfurization tank has a side hole 62, the position of the side hole of the No. 1 desulfurization tank is welded with a U-shaped insert 63, and the bottom circle 7 is pasted inside the No. 1 desulfurization tank. The No. 1 desulfurization tank is welded to the bottom circle, the bottom circle is fixedly connected to the ring 8, the U-shaped insert is fixedly connected to the outer U-shaped stopper 64, and the No. 1 circulation oil pipe 61 is welded to a U-shaped Inserting plate 65, the U-shaped inserting plate is inserted into the inner side of the outer U-shaped retainer, and an outer sealing ring 66 is installed between the U-shaped insert and the outer U-shaped retainer. An inner sealing ring ...

Embodiment 2

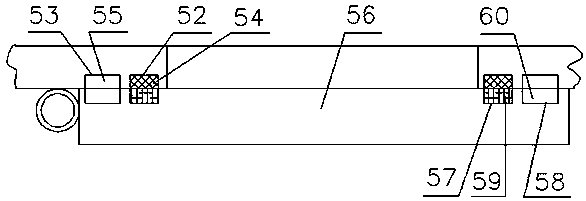

[0031] In the petroleum smelting desulfurization device described in Example 1, the left half-mouth-shaped clamping member 12 is bonded to the left slot, and the primary filter device includes an elastic clamping frame 13, and the upper and lower sides of the primary filter membrane 14 All are connected with an elastic clamping frame 13, the cross-section of an elastic clamping frame is U-shaped, the elastic clamping frame clamps the primary filter membrane 14, and the left half mouth-shaped clamping member clamps Hold the bottom of the elastic clamping frame, the left and right sides of the left half mouth-shaped clamping piece 12 are connected with thumb screws 15, and the two thumb screws are relatively fastened to clamp the An elastic clip on the bottom of the frame.

[0032] An elastic clamping frame can hold the primary filter membrane very well, and it is connected and fixed by the left half-mouth-shaped clamping piece, and the left half-mouth-shaped clamping piece is r...

Embodiment 3

[0034] In the petroleum smelting desulfurization device described in Example 1, the middle slot is bonded with the half-mouth-shaped clamping member 16, and the secondary filter device includes two elastic clamping frames 17, and the upper and lower sides of the secondary filter membrane 18 Both are connected to two elastic clamping frames 17, the cross-section of the two elastic clamping frames is U-shaped, the two elastic clamping frames clamp the secondary filter membrane 18, and the middle half-mouth-shaped clamping member clamps Hold the bottom of the two elastic clamping frames, the left side and the right side of the middle half-mouth-shaped clamping piece 16 are connected with thumb screws, and the two thumb screws are relatively fastened to clamp the Two elastic clips are attached to the bottom of the frame.

[0035] The second elastic clamping frame can hold the secondary filter membrane very well, and it is connected and fixed through the half-mouth-shaped clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com