A self-generated tic wear-resistant steel with uniform particles and its preparation method

An in-situ self-generated, uniform particle technology, applied in the field of alloy steel, to achieve uniform distribution, concentrated self-generated particle size distribution range, and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

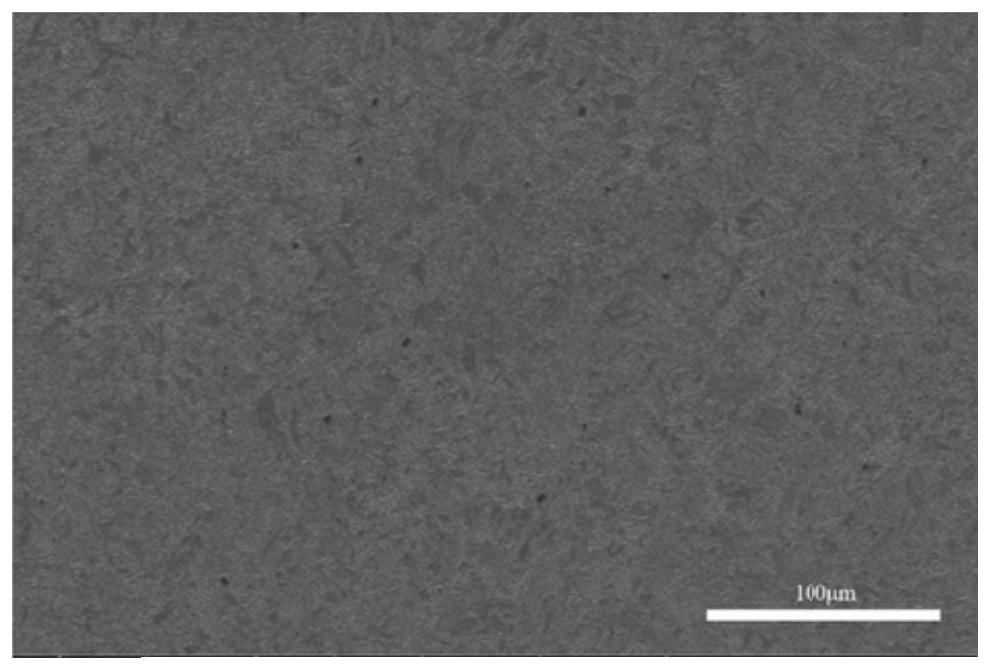

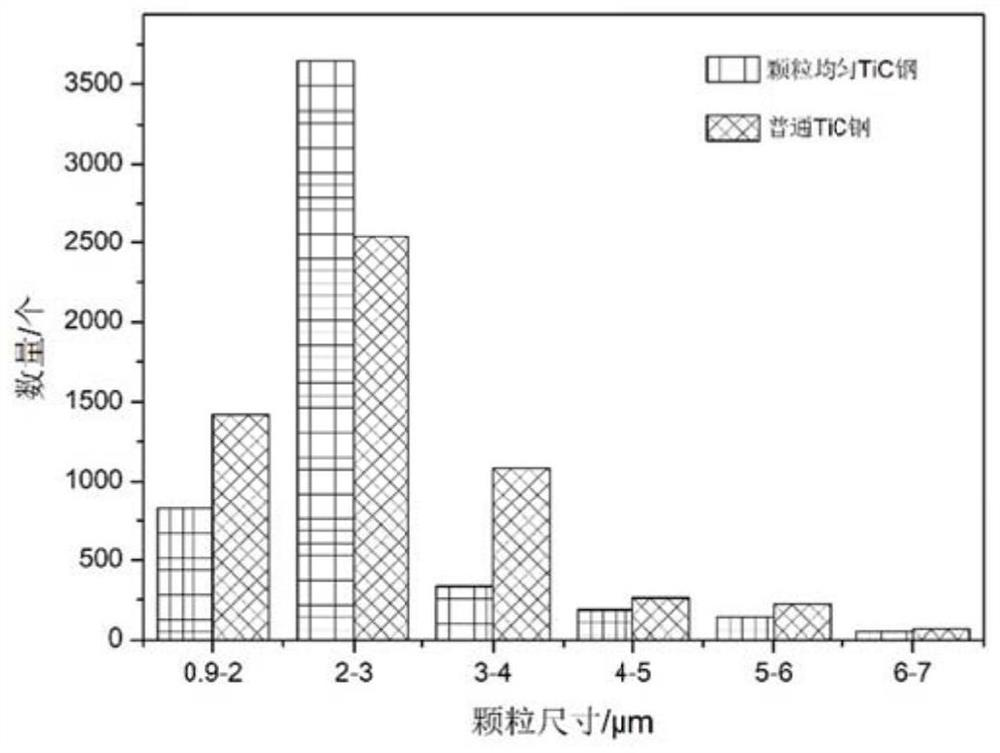

[0023] The chemical composition of in-situ self-generated TiC wear-resistant steel with uniform particles is calculated by weight percentage, C 0.22%, Si 0.24%, Mn1.85%, Ni 0.30%, Ti 0.27%, Al 0.17%, Cr 0.37%, Mo 0.18%, P 0.008%, Nb0.015%, S 0.002%, RE 0.07%, the balance is Fe and unavoidable inclusions, ingot size 80*100*300mm 3 . The steel ingot was heated at 1220°C for 2 hours, and two-stage controlled rolling was carried out. The rough rolling start temperature is 1088°C, the pass reduction rate is 31%, the 2-pass deformation is 62%, and the thickness of the intermediate billet is controlled at 30mm. The starting temperature of the finish rolling is 955°C, and the reduction rate of each pass is 11%. After 2 passes of rolling, the thickness of the final product reaches 12mm. Air-cool to room temperature after final rolling. The steel plate cooled to room temperature was quenched at 900°C for 30 minutes, and then water quenched to room temperature. The quenched steel pla...

Embodiment 2

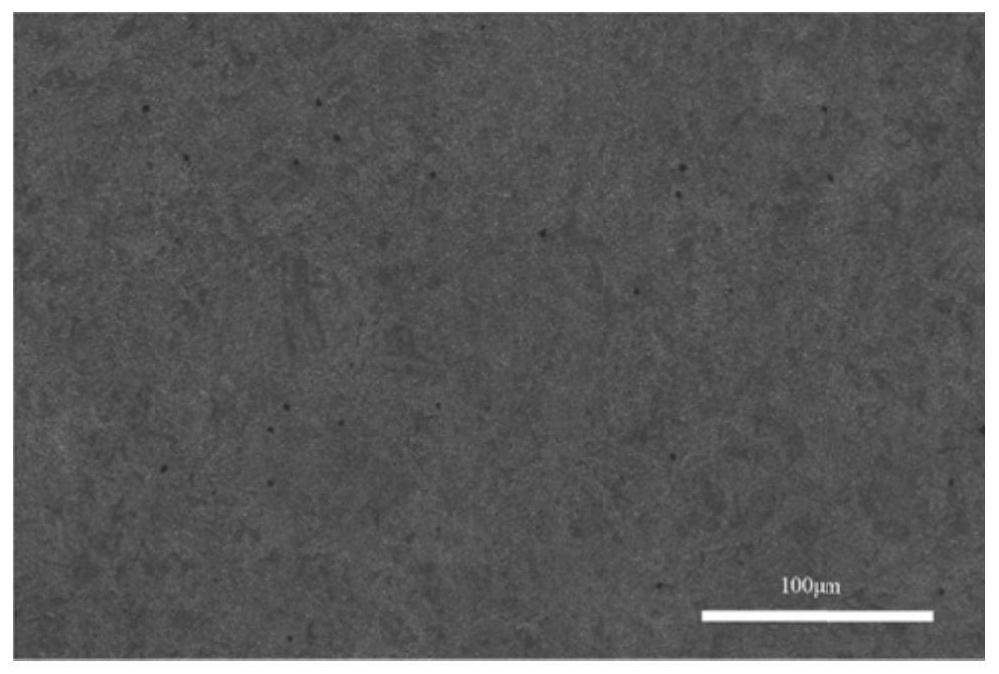

[0027] The chemical composition of in-situ self-generated TiC wear-resistant steel with uniform particles is calculated by weight percentage, C 0.23%, Si 0.25%, Mn1.93%, Ni 0.27%, Ti 0.28%, Cr 0.35%, Al 0.19%, Mo 0.19%, P 0.008%, Nb0.014%, S 0.002%, RE 0.06%, the balance is Fe and unavoidable inclusions, ingot size 80*100*300mm 3 . The steel ingot was heated at 1220°C for 2 hours, and two-stage controlled rolling was carried out. The rough rolling start temperature is 1087°C, the pass reduction rate is 31%, the 2-pass deformation is 62%, and the thickness of the intermediate billet is controlled at 30mm. The start rolling temperature of the finish rolling is 954°C, and the reduction in each pass is 11%. After 2 passes of rolling, the thickness of the final product reaches 12mm. Air-cool to room temperature after final rolling. The steel plate cooled to room temperature was quenched at 900°C for 30 minutes, and then water quenched to room temperature. The quenched steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com