A kind of operation control method in the production passivation product

An operation control and product technology, applied in the direction of metal material coating process, etc., can solve problems such as affecting the quality of strip steel, wrong parameter setting, and should not be passivated, and achieve automatic control, avoid mistakes, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

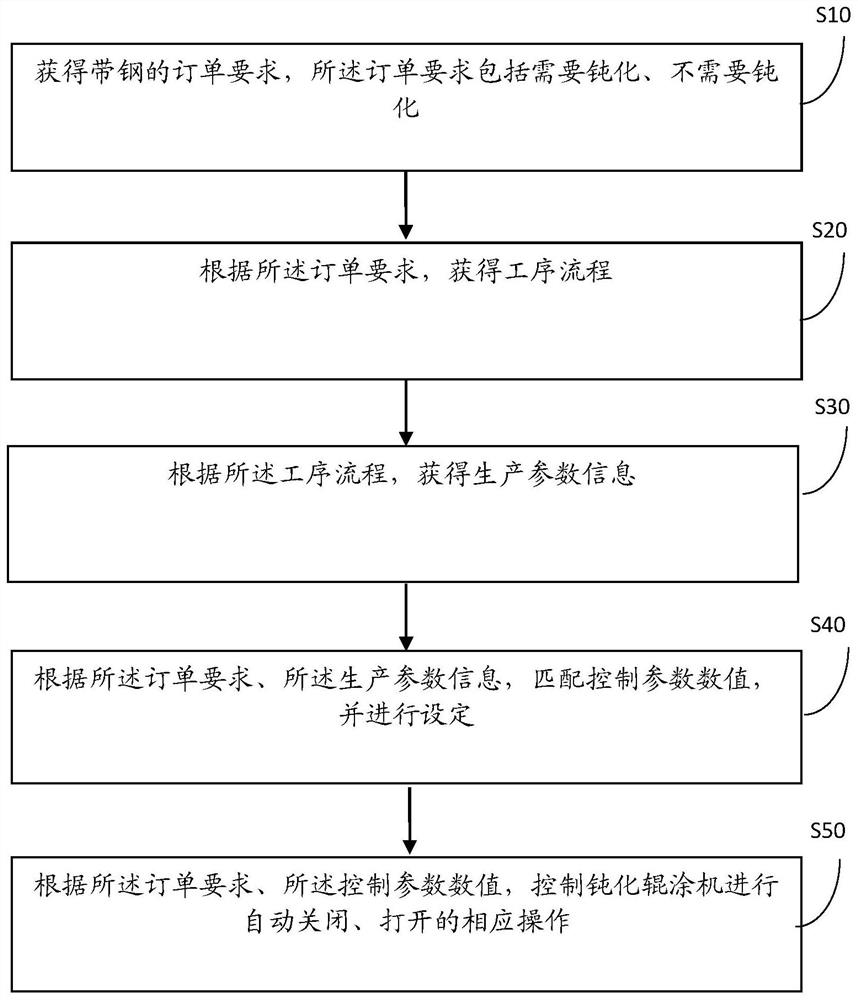

[0022] figure 1 It is a schematic flowchart of an operation control method for producing passivated products in an embodiment of the present invention. The embodiment of the present invention provides an operation control method in the production of passivated products, please refer to figure 1 , the method includes:

[0023] Step 10: Obtain the order requirements for the steel strip, the order requirements include whether passivation is required or not.

[0024] Step 20: Obtain the process flow according to the order requirements.

[0025] Step 30: Obtain production parameter information according to the process flow.

[0026] Step 40: Match and set control parameter values according to the order requirements and the production parameter information.

[0027] Step 50: According to the order requirements and the control parameter values, control the passivation roller coater to perform corresponding operations of automatic closing and opening.

[0028] Specifically, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com