Light base system and construction method for bridge deck sidewalk

A technology for sidewalks and sidewalk slabs, which is applied in bridges, bridge materials, bridge construction, etc., can solve the problems of affecting the durability of bridges, increasing the weight of curbs and guardrail bases, etc. The effect of small material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

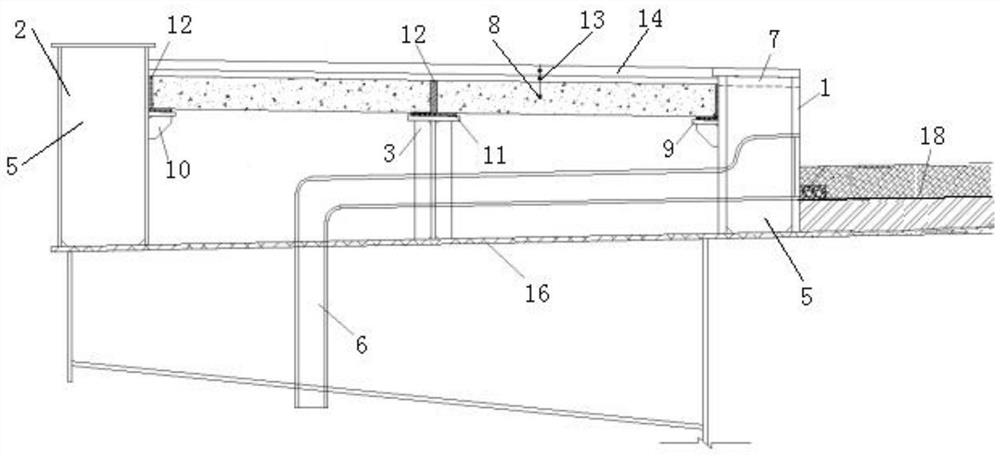

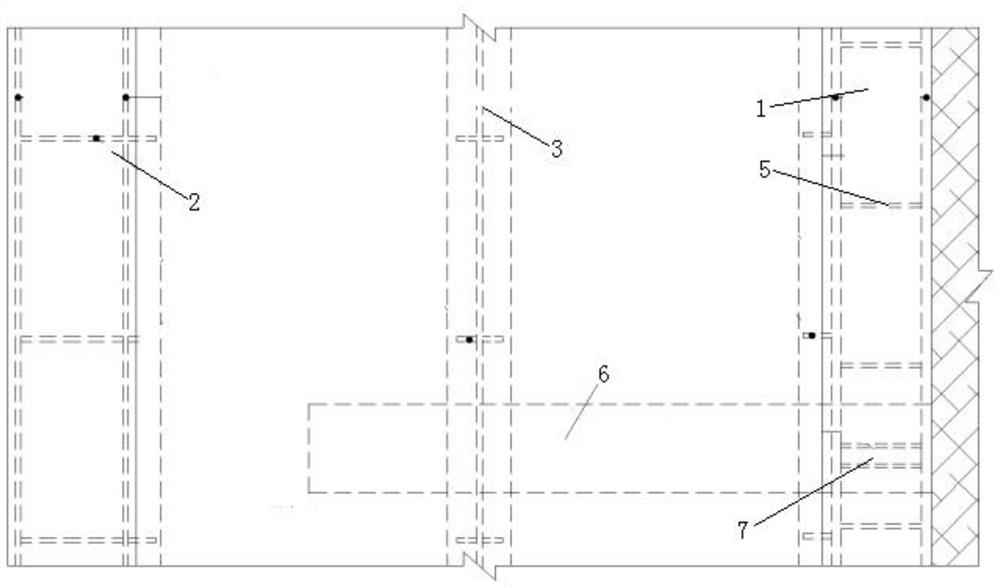

[0028] from Figure 1-2 It can be seen that a light base system for bridge deck sidewalks in this embodiment is actually applied to steel bridges, including the inner steel base 1 and the outer steel base 2, and the inner steel base 1 and the outer steel base 2. The bottom is respectively provided with base stiffeners 5, and the base stiffeners 5 are used to ensure the rigidity and integrity of the base. The surfaces of the inner steel base 1 and the outer steel base 2 are all provided with supporting steel plates 9, and the supporting steel plates 9 Supporting stiffeners 10 are installed at the bottom, rubber pads 11 are laid on the surface of the supporting steel plates 9, and the upper surface of the rubber pads 11 carries sidewalk boards 8, which are in contact with the side walls of the inner steel base 1 and the outer steel base 2 Waterstops 12 are filled on all surfaces, and waterstops 12 are also filled between adjacent sidewalk slabs 8. A small drain pipe 7 is provide...

Embodiment 2

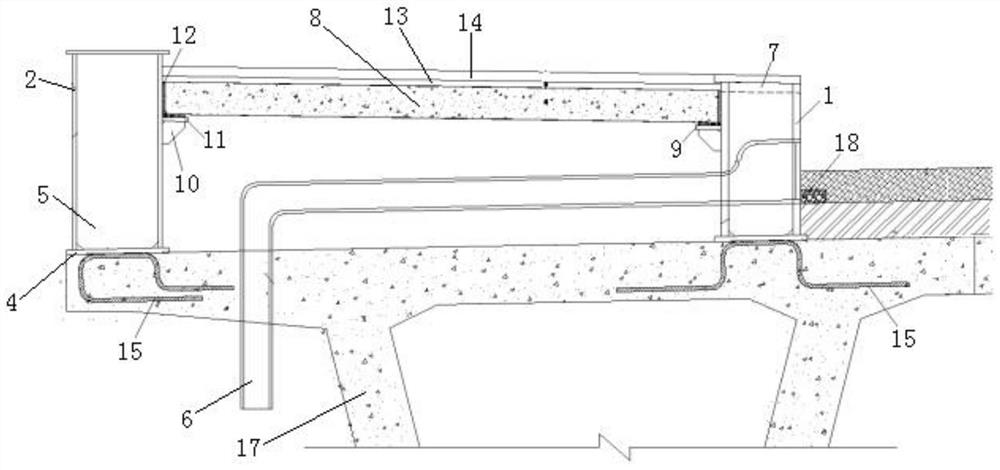

[0033] from Figure 3-4 It can be seen that a light base system for bridge deck sidewalks in this embodiment is actually applied to concrete bridges, including the inner steel base 1 and the outer steel base 2, and the inner steel base 1 and the outer steel base 2. The bottom is respectively provided with base stiffeners 5, and the base stiffeners 5 are used to ensure the rigidity and integrity of the base. The surfaces of the inner steel base 1 and the outer steel base 2 are all provided with supporting steel plates 9, and the supporting steel plates 9 Supporting stiffeners 10 are installed at the bottom, rubber pads 11 are laid on the surface of the supporting steel plates 9, and the upper surface of the rubber pads 11 carries sidewalk boards 8, which are in contact with the side walls of the inner steel base 1 and the outer steel base 2 Waterstops 12 are filled on all surfaces, and waterstops 12 are also filled between adjacent sidewalk slabs 8. A small drain pipe 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com