Bridge girder erection machine and construction method for erecting widened girder

A bridge erecting machine and wide beam technology, applied in the field of bridge construction, can solve the problems of inclined piers, complex structure, few supporting points, etc., and achieve the effect of reasonable supporting structure, simple overall structure and good overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

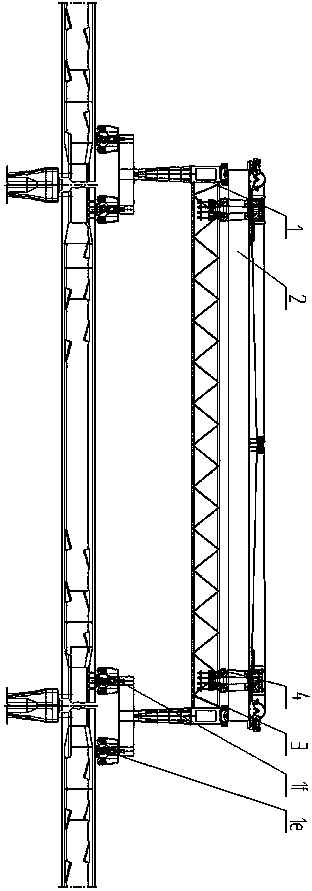

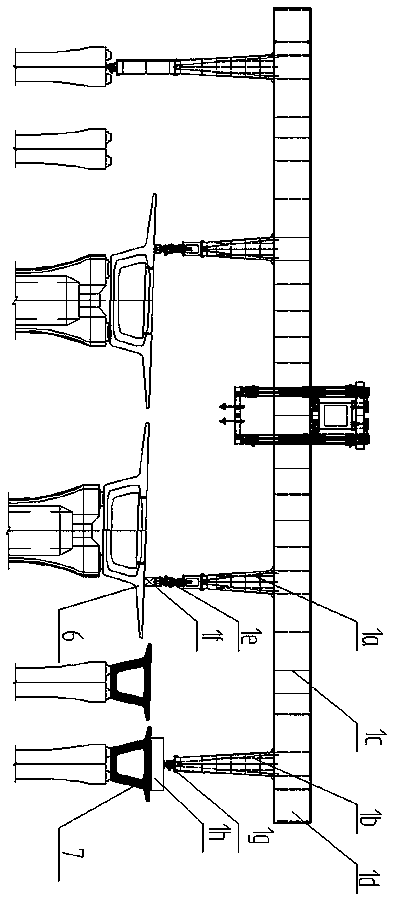

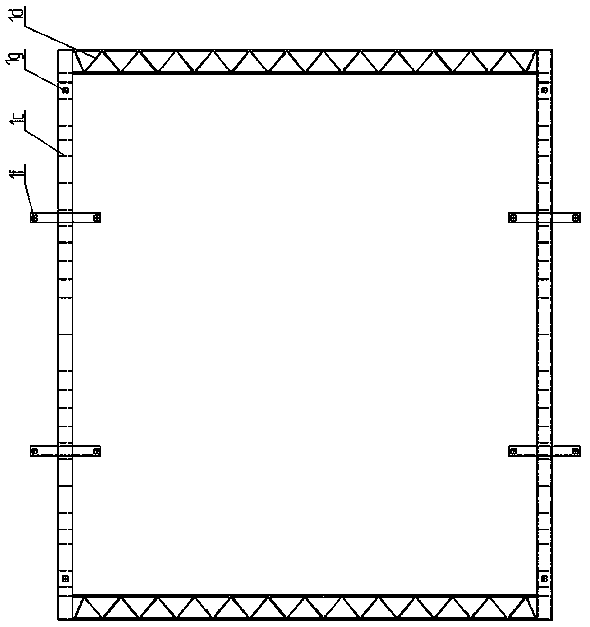

[0035] The bridge erecting machine used for erecting the widened beams according to the present invention belongs to bridge construction equipment, and is especially suitable for widening the existing bridges and the construction of the widened beams of the ramps of the entrances and exits of expressways / viaducts. The general structure of the widened beams is as follows: figure 2 As shown in 7, it is erected on both sides of the main line box girder 6, and the widening beam includes a plurality of widening beam sections, and each widening beam section includes one or more than two parallel box girders. The present invention will be further described below in conjunction with the accompanying drawings of the present invention. It should be pointed out that the term "longitudinal" used in it refers to the length direction of the bridge, "horizontal" refers to the direction perpendicular to the length direction of the bridge on the horizontal plane, and "front" refers to the brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com