Track moving type rebar machining shed

A mobile, processing shed technology, used in special buildings, small buildings, building types, etc., can solve the problems of loading and unloading problems that cannot be well solved, material quality cannot be guaranteed, and costs increase, saving loading and unloading man-hours. , The effect of saving crane shift costs and improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below with reference to accompanying drawing and embodiment:

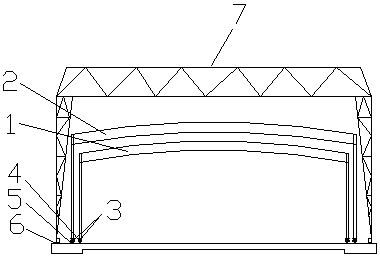

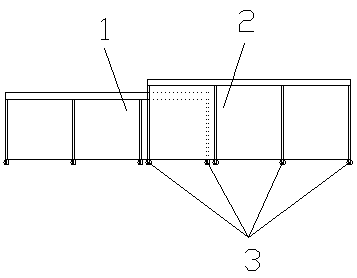

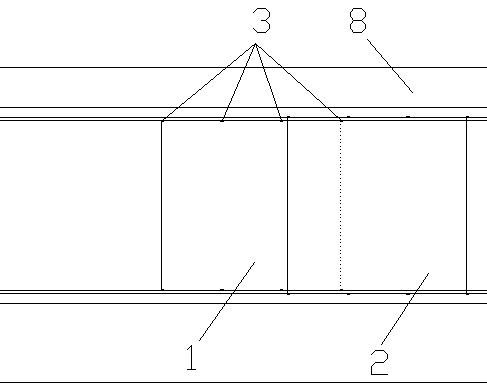

[0028] attached Figure 1-3 It can be seen that a track-moving steel bar processing shed includes a standardized factory shed,

[0029] The standardized shed includes an inner rail movable standardized shed assembly 1 and an outer rail movable standardized shed assembly 2; the inner rail movable standardized shed assembly 1 is arranged inside the outer rail movable standardized shed assembly 2;

[0030] The inner track mobile standardized factory shed assembly includes the inner standardized factory shed, and the inner standardized factory shed includes a load-bearing column; the lower part of the load-bearing column is provided with a slotted mobile roller 3; the slotted mobile roller 3 is arranged on the inner track 4;

[0031] The outer track mobile standardized factory shed assembly includes the outer standardized factory shed, and the outer standardized fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com