Construction method suitable for excavation of super-large section underground chamber and fixing of steel arch frame

A technology for underground chambers and extra-large cross-sections is applied in underground chambers, earthwork drilling, shaft equipment, etc., which can solve the problems of high construction cost and large waste of supporting structure funds, and achieve the effect of speeding up the construction progress and saving project investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

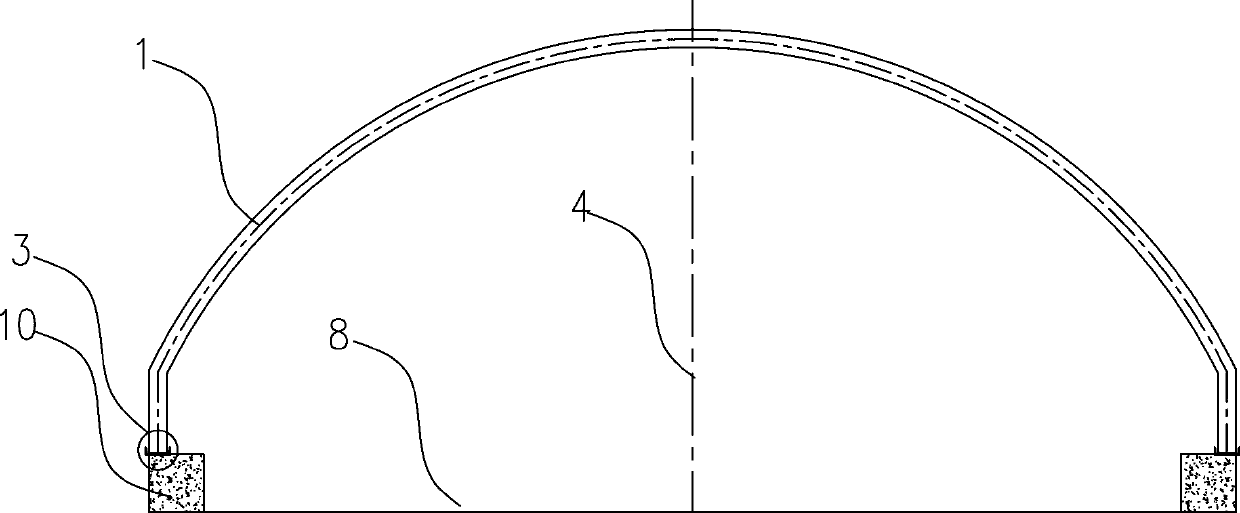

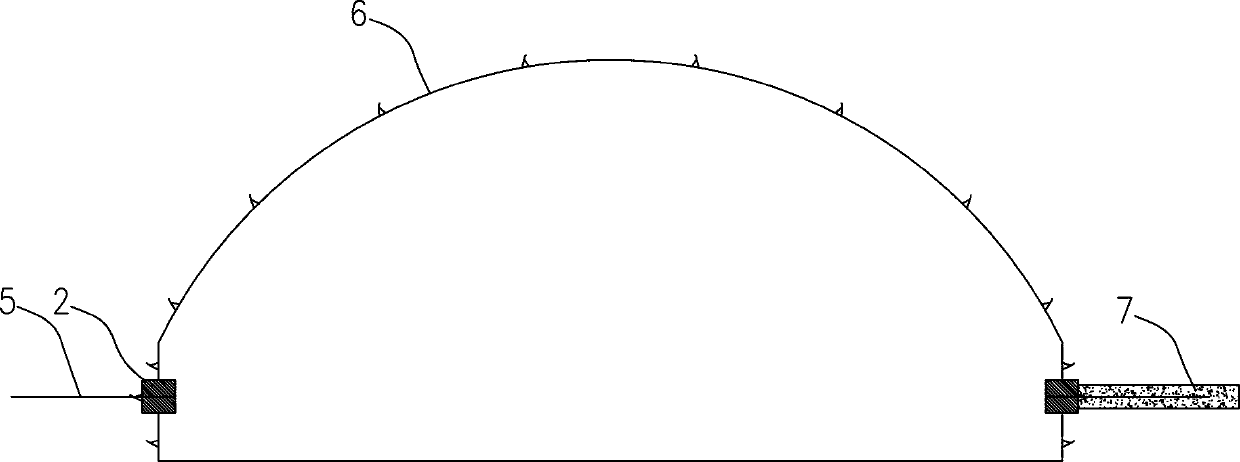

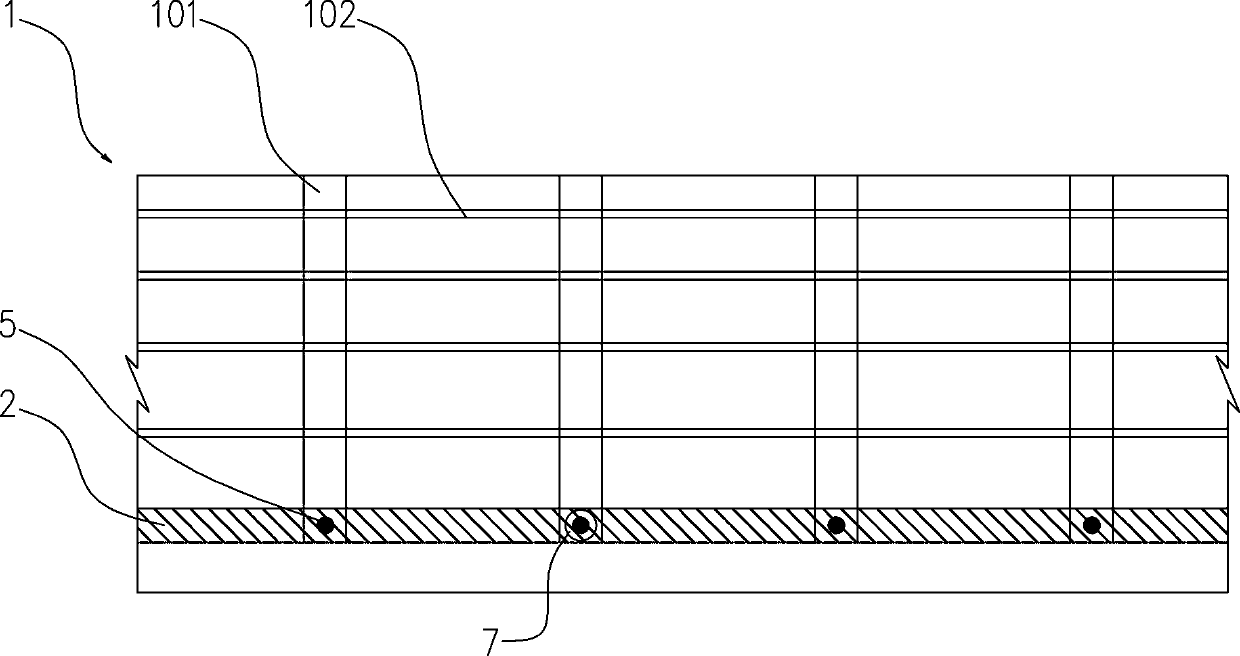

[0038] Such as Figure 1~4 Among them, a construction method suitable for the excavation of extra-large-section underground chambers and the fixing of steel arches, including the following steps:

[0039] S1, divide the extra-large section underground chamber into at least two layers from top to bottom for excavation;

[0040] In the preferred scheme, the excavation height of the top arch layer is 2.5±0.3m below the intersection of the cavern vault and the side wall.

[0041] In a preferred solution, the installation height of the dome arch 1 extends downward in the vertical direction by 1.5±0.2m in addition to the arc height of the dome.

[0042] S2. Excavation construction of the top arch layer, and a section of the top arch is excavated, and the dome arch frame 1 is installed close to the cave wall;

[0043] S3. After the dome arch 1 is installed for a section, the dome is sprayed with concrete, and longitudinal rock anchor beams 2 are arranged along the chamber side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com