Horizontal underground culvert pipe blockage dredging robot and working method thereof

A horizontal and robotic technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve problems such as complexity, large amount of engineering, and no cleaning equipment, so as to reduce workload, reduce dredging costs, and ensure dredging effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

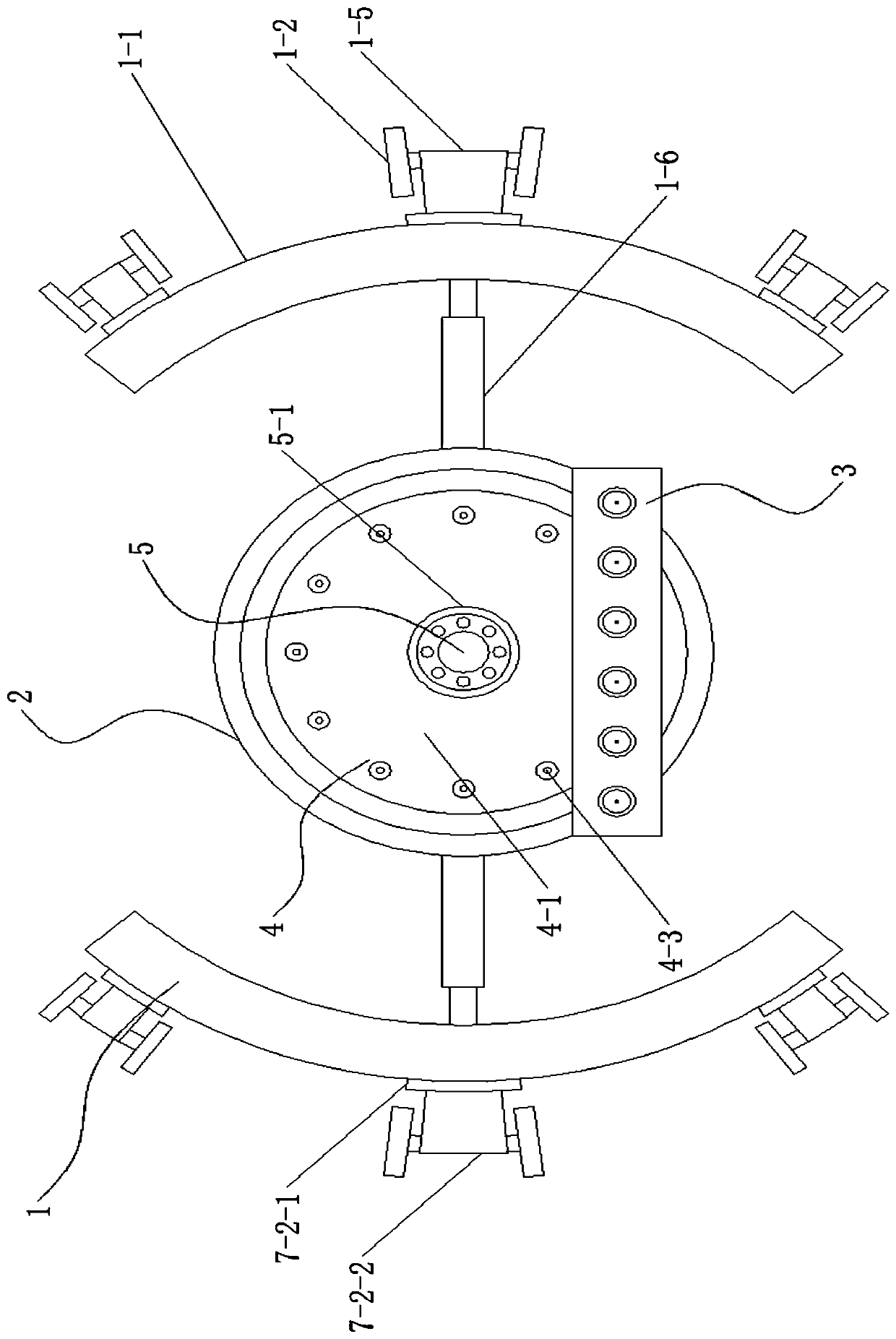

[0049] combine Figure 1-Figure 9 As shown, a horizontal underground culvert pipe blockage dredging robot disclosed in this embodiment includes a traveling mechanism 1, a dredging body 2, a beating dredging mechanism 3, a high-pressure dredging mechanism 4 and a camera mechanism 5; the dredging body 2 is arranged inside the walking mechanism 1, and the front end of the dredging body 2 is provided with a high-pressure dredging mechanism 4, and the high-pressure dredging mechanism 4 is connected to an external high-pressure water pump through a transmission line 6, and the high-pressure water pump is connected to an external water source The camera mechanism 5 is arranged in the middle of the high-pressure dredging mechanism 4, and the camera mechanism 5 is connected to the external host computer through the transmission line 6. A silting mechanism 3, the rear end of the dredging fuselage 2 is provided with a driven walking mechanism 7;

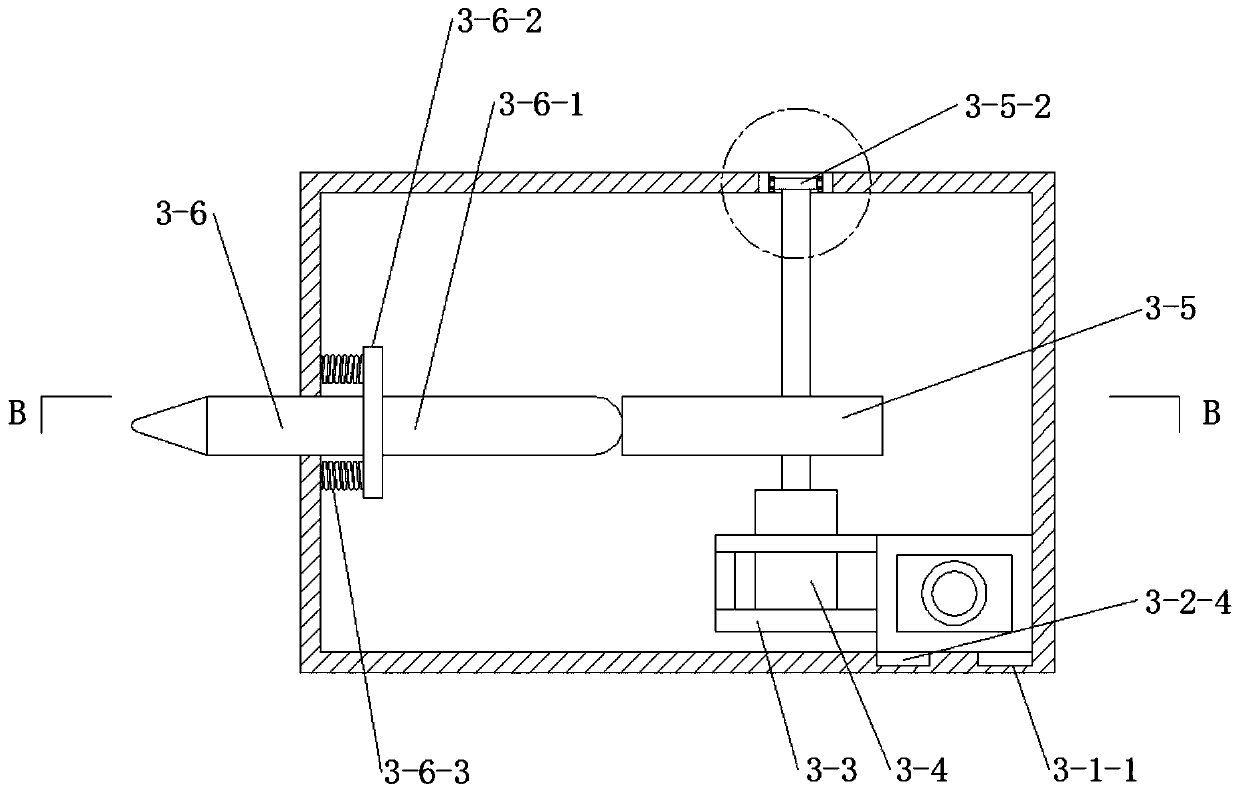

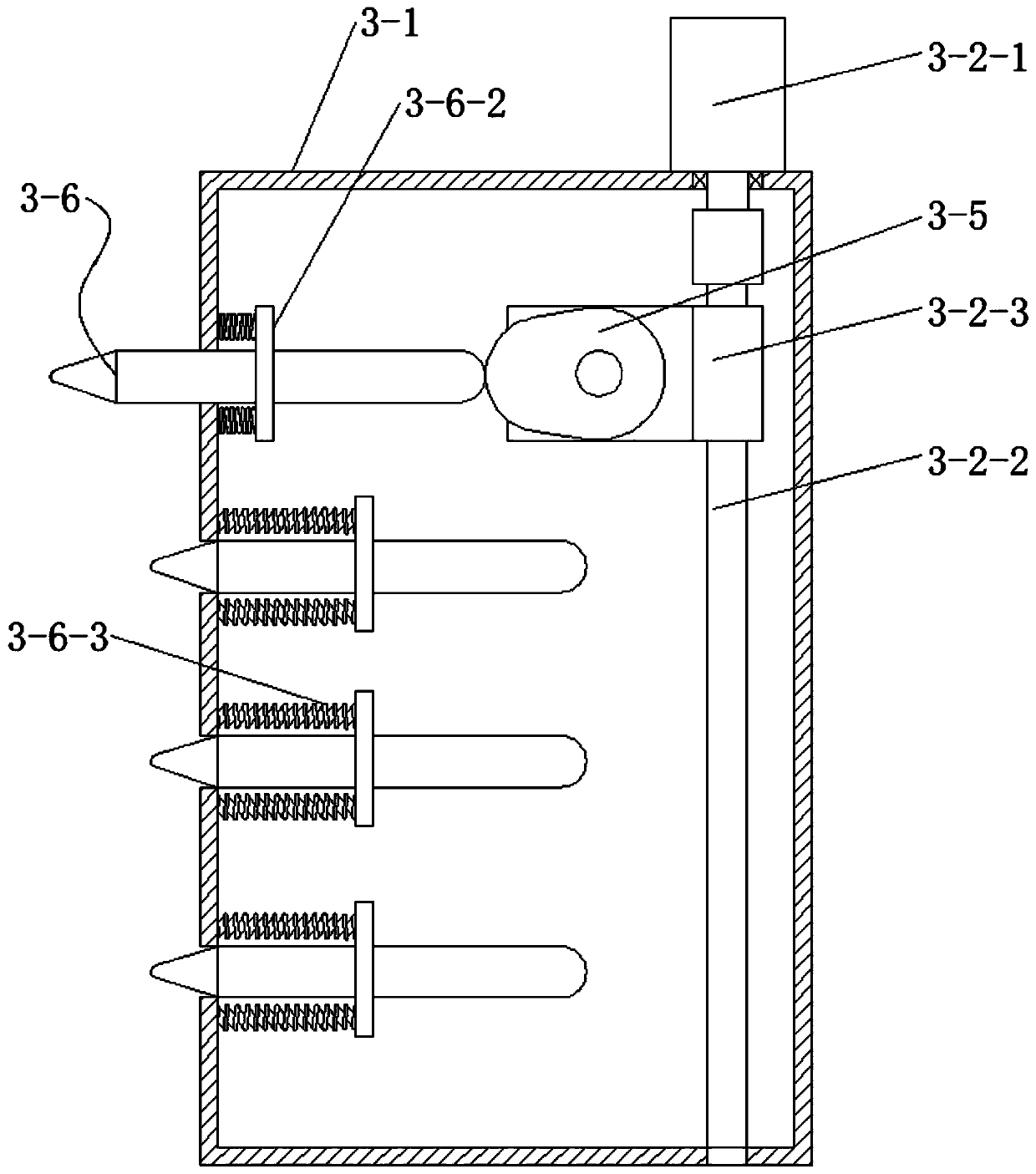

[0050] The beating and dredging mechani...

Embodiment 2

[0053] On the basis of Embodiment 1, the walking mechanism 1 in this embodiment includes two sets of symmetrically arranged arc-shaped walking plates 1-1, and the outer end faces of the arc-shaped walking plates 1-1 are equidistantly provided with three sets of driving and moving rollers. 1-2, each of the driving mobile rollers 1-2 is fixedly connected to the main shaft of a group of roller driving motors 1-3, and the roller driving motors 1-3 are arranged on the driving roller frame 1 through the shock absorbing device 1-4 -5, the driving roller frame 1-5 is arranged on the outer end surface of the arc-shaped walking plate 1-1, and the arc-shaped walking plate 1-1 connects with the dredging body through the culvert tube adaptive device 1-6 2 fixed connections;

[0054] The driven traveling mechanism 7 includes two groups of symmetrically arranged driven arc-shaped plates 7-1, and three sets of driven rollers 7-2 are equidistantly arranged on the outer end surface of the drive...

Embodiment 3

[0056] On the basis of Embodiment 1, the shock absorber 1-4 in this embodiment includes a group of lower shock absorbers 1-4-2 and upper shock absorbers 1-4-1, and the driving roller frame 1-5 and The driven roller 7-2 frames all include a set of installation arc plates 7-2-1, and the installation arc plates 7-2-1 are welded on the arc walking plate 1-1 and the driven rollers. On the arc-shaped plate 7-1, a group of installation columns 7-2-2 are welded on the installation arc-shaped plate 7-2-1, and shock-absorbing grooves are processed on the installation columns 7-2-2. The bottom end of the shock absorbing groove is fixed with the lower shock absorbing device 1-4-2, and the lower shock absorbing device 1-4-2 is connected with the roller drive motor 1-3 and the driven roller 7-2. The rotating shaft bearings are fixedly connected, and the upper ends of the rotating shaft bearings of the roller drive motor 1-3 and the driven roller 7-2 are also connected with the upper shock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com