Dredging equipment for water conservancy river channel

A technology for river channels and equipment, applied in mechanically driven excavators/dredgers, construction, earthmoving machines/shovels, etc. Reduce the cost of dredging, improve treatment efficiency, and improve the effect of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

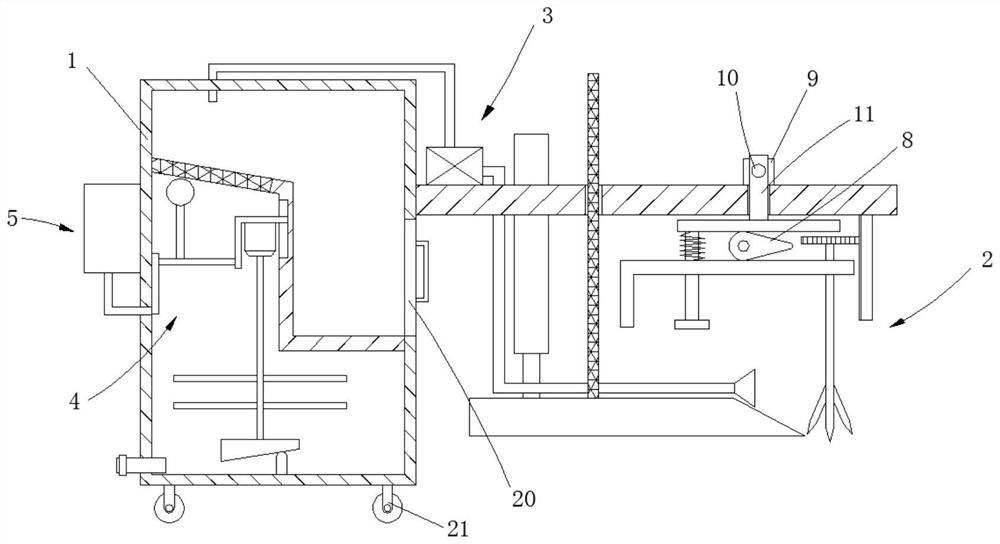

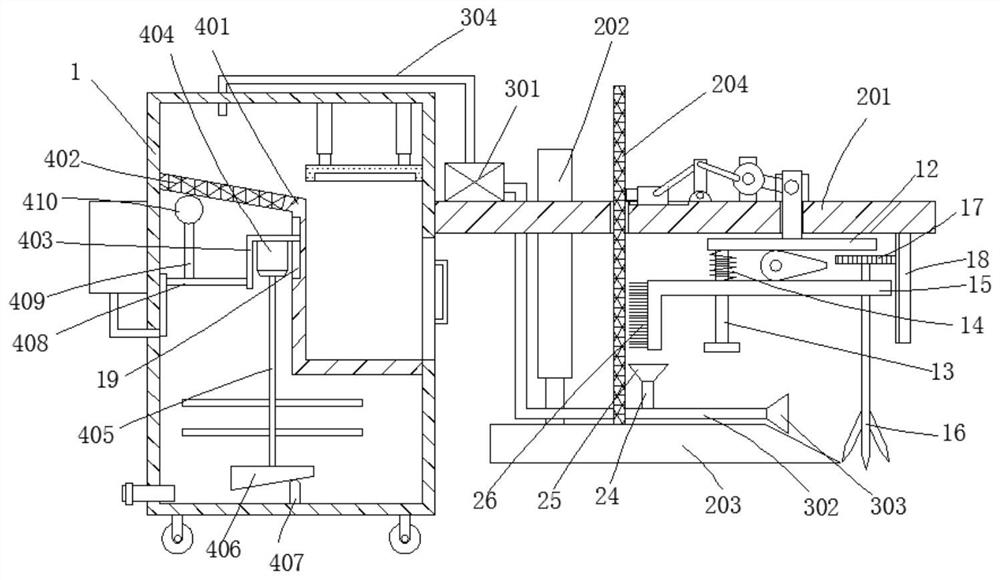

[0038] see Figure 1-6 , the present invention provides a technical solution: a dredging equipment for water conservancy rivers, including a main body box 1, a loosening mechanism 2, a suction mechanism 3, a separation mechanism 4 and a processing mechanism 5, and the loosening mechanism 2 includes a horizontal plate 201, telescopic rod 202, push plate 203 and filter screen 204, horizontal plate 201 is horizontally fixed on the right side of main body box 1, telescopic rod 202 is plugged on the horizontal plate 201, and push plate 203 is fixedly connected to the output of telescopic rod 202 end, and the right end of the push plate 203 is inclined, the filter screen 204 is vertically fixed on the top of the push plate 203, the horizontal plate 201 is provided with a through groove 6, and the filter screen 204 extends to the top of the horizontal plate 201 through the through groove 6 .

[0039] Wherein, the loosening mechanism 2 also includes a motor 9, a screw mandrel 10, a m...

Embodiment 2

[0045] Compared with embodiment 1, its difference is:

[0046] Wherein, the bottom of horizontal plate 201 is also provided with cleaning mechanism, and cleaning mechanism comprises branch pipe 24, the second mud suction cover 25 and cleaning brush 26, and branch pipe 24 is vertically arranged on the position of connecting pipe 302 near the right side of filter screen 204, and the second The mud pumping cover 25 is installed on the end of the branch pipe 24, the lifting rod 15 is L-shaped, and the cleaning brush 26 is bonded to the side of the lifting rod 15 near the filter screen 204.

Embodiment 3

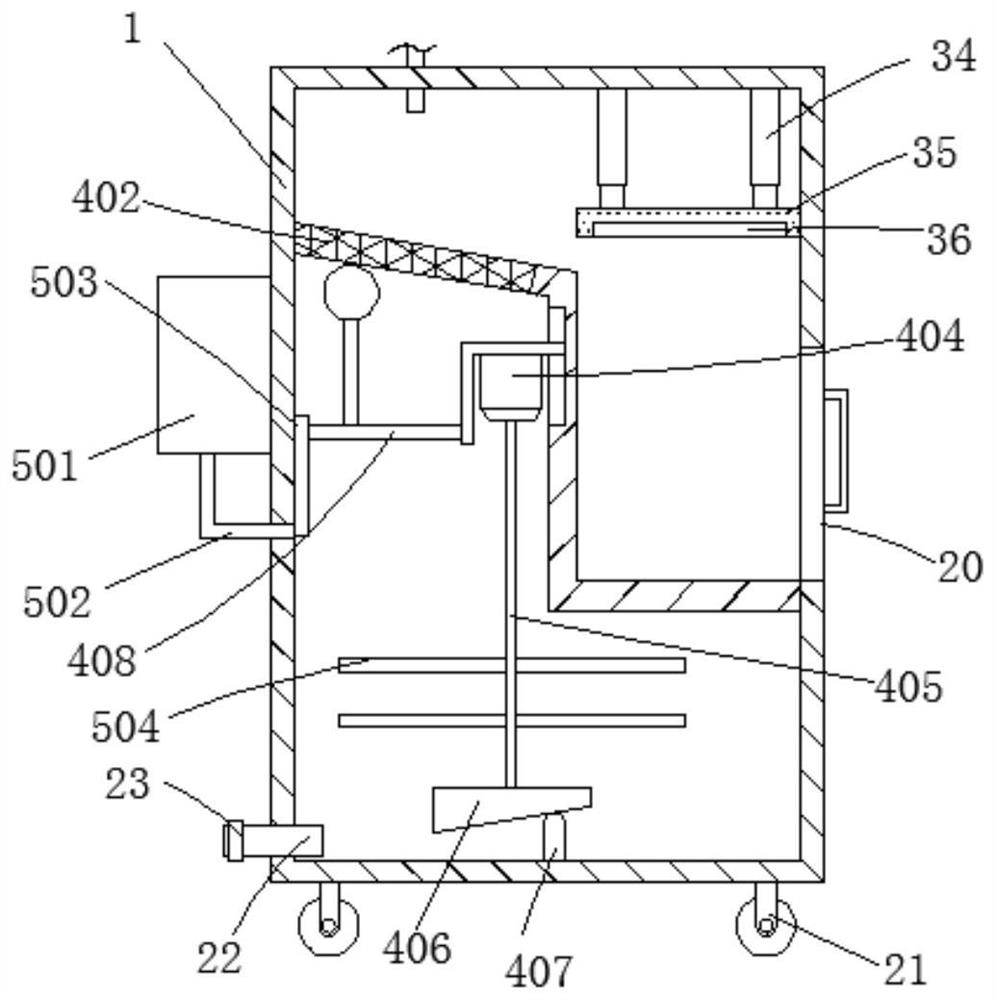

[0048] Compared with embodiment 2, its difference is:

[0049] Wherein, the top of horizontal plate 201 is also provided with auxiliary mechanism, and auxiliary mechanism comprises support rod 27, rotating disk 28, connecting rod 29, slide block 30 and projection 31, and supporting rod 27 is affixed on the top of horizontal plate 201, and rotating disk 28 rotates Connected to the front side of the support rod 27, a transmission member 32 is provided between the turntable 28 and the screw mandrel 10, and a slide rail 33 is provided on the top of the horizontal plate 201, the slide block 30 is slidably connected to the slide rail 33, and the connecting rod 29 is hinged On the horizontal plate 201 , the left and right ends of the connecting rod 29 are respectively hinged with the turntable 28 and the slider 30 , and the projection 31 is fixedly connected to the side of the slider 30 close to the filter screen 204 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com