Equipment realizing quick measurement on small assembling clearance

An assembly gap and fast technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as high requirements for professional knowledge, difficult on-site application by workers, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

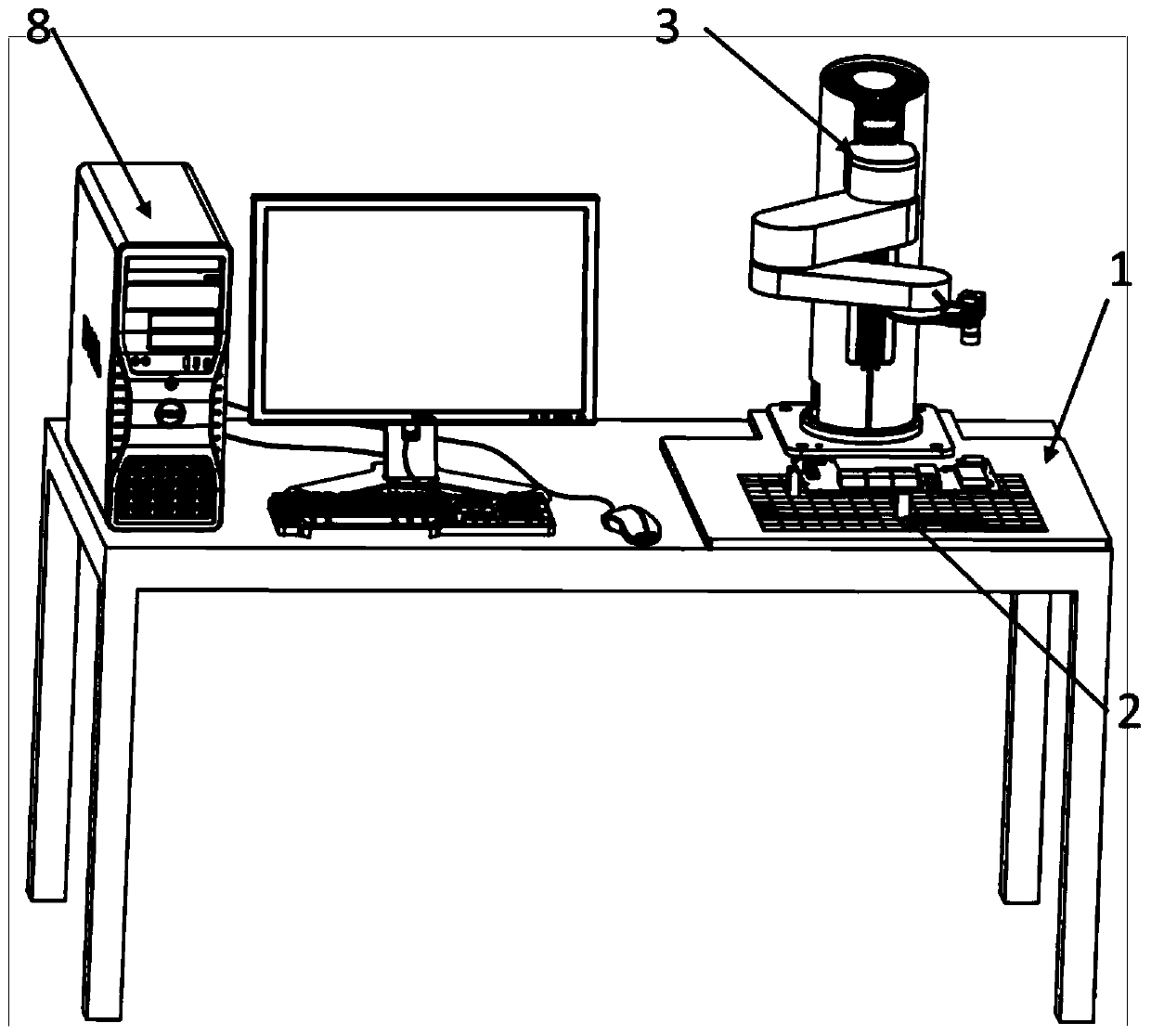

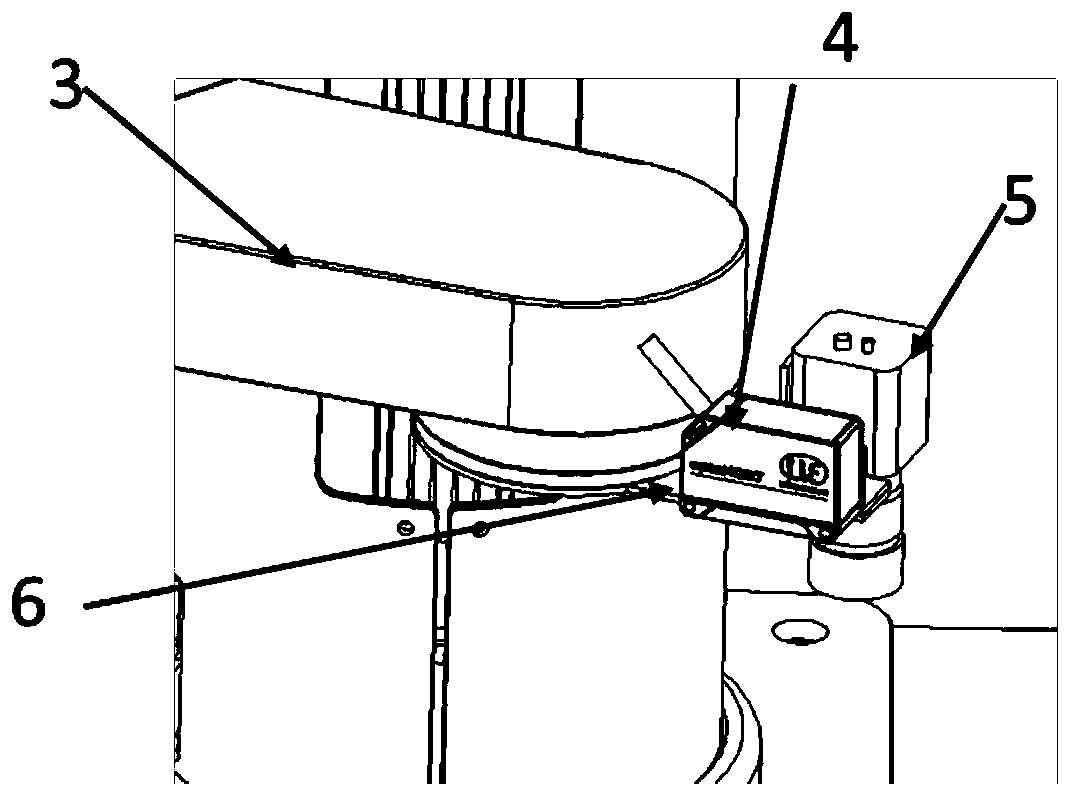

[0036] A kind of equipment that realizes the rapid measurement of tiny assembly gap shown in this embodiment, see figure 1 As shown, it mainly includes: a base 1, a support 2, a horizontal four-axis collaborative robot 3 and an industrial computer 8.

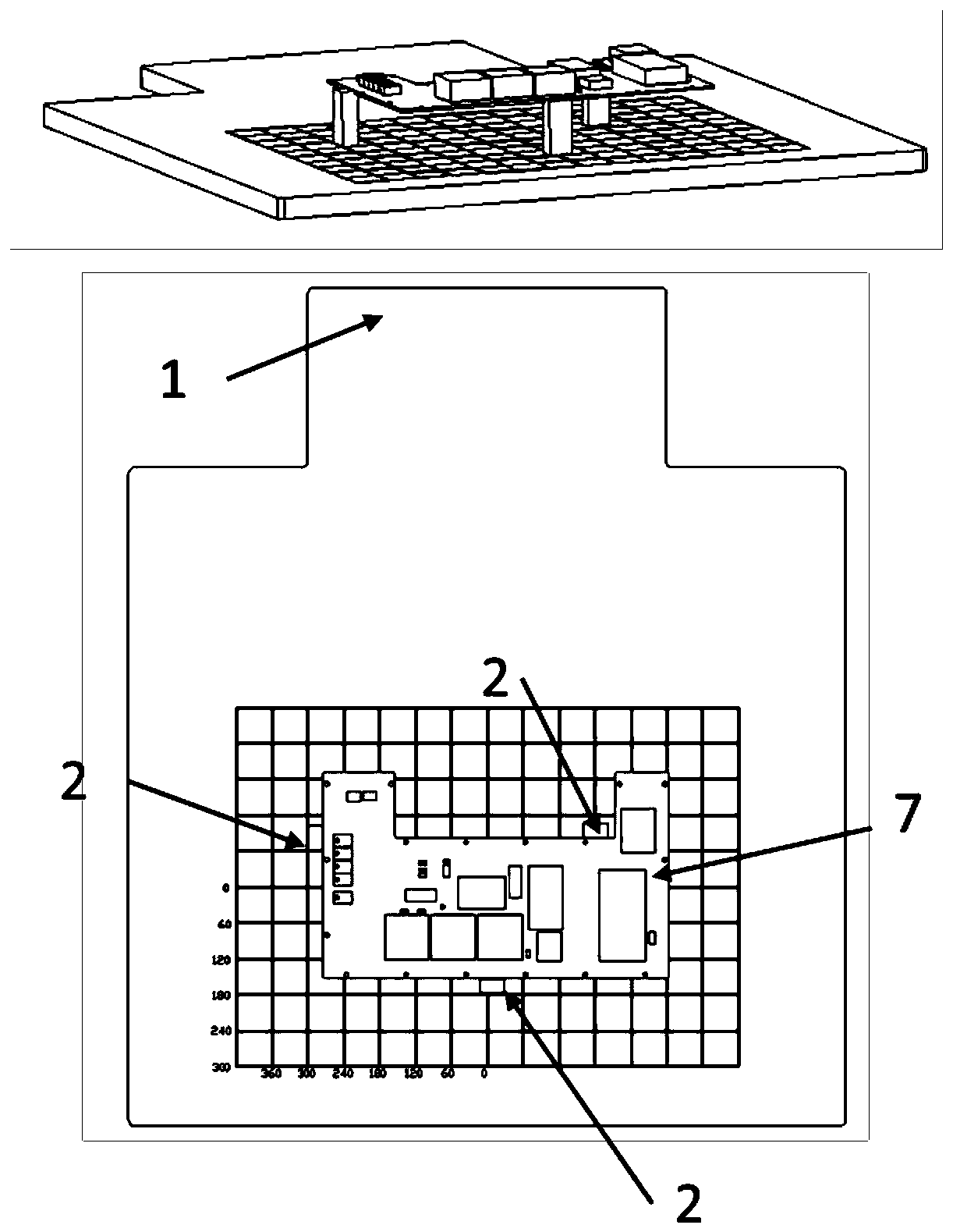

[0037] The base 1 is used to install the horizontal four-axis collaborative robot 3 and the parts 7 to be tested. Its features include: adopting stainless steel plate and weight-reducing design, the surface is polished and smooth, setting mutually perpendicular rectangular grooves to form grid lines, and marking the scale value according to the groove position.

[0038] Bearing 2 has 3-6, is placed on the base. The bottom of the support is designed with a magnetic device, which can be adsorbed on the base and can be manually moved to different positions as needed. There is a 2mm step on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com