Optical fiber point diffraction device and measurement method for three-dimensional vibration measurement

A technology of three-dimensional vibration and measurement method, which is applied in the field of optical measurement, can solve problems such as difficult measurement and dynamic measurement of difficult-to-measure objects, and achieve good real-time performance, continuous dynamic measurement, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

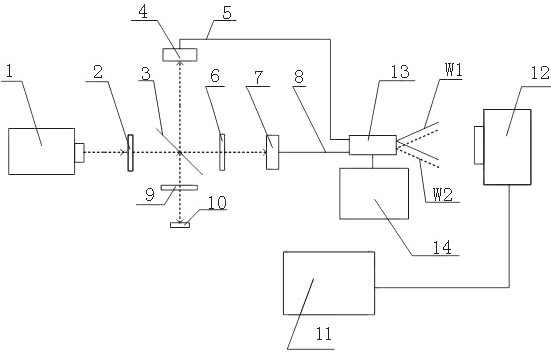

[0019] Example: such as figure 1 Shown is a fiber optic point diffraction device for three-dimensional vibration measurement, which includes a laser 1, a polarizer 2, a polarization beam splitter 3, a half-wave plate 6, a coupler I 4, a subwavelength aperture single-mode fiber 5, a quarter splitter One wave plate 9, mirror 10, coupler II 7, sub-wavelength aperture single-mode fiber II 8, high-speed CCD detector 12, measuring probe 13, computer 11. figure 1 The dotted lines with arrows in the middle represent optical paths, and the solid lines without arrows represent circuit connections. Laser 1 is a polarized laser. After passing through polarizer 2, the laser light generated by laser 1 is divided into two beams by polarizing beam splitter 3, the transmitted light p and the reflected light s. The transmitted light p passes through the half-wave plate 6 and then is coupled into the fiber coupler. II 7, then point diffraction spherical wavefront W2 is generated at the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com