Rolling bearing high-speed vibration testing method

A rolling bearing and vibration testing technology, which is applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as poor vibration performance of bearings, existence of differences, and inability to characterize bearing vibration, etc., to reduce economic costs loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

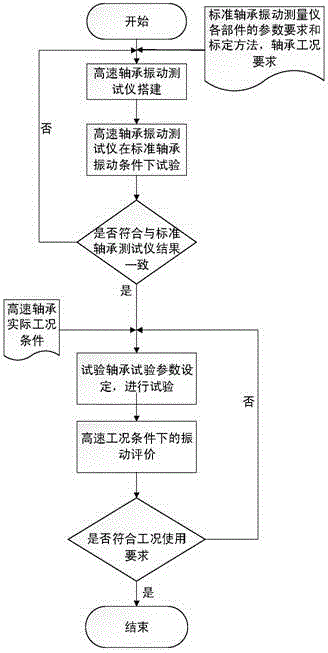

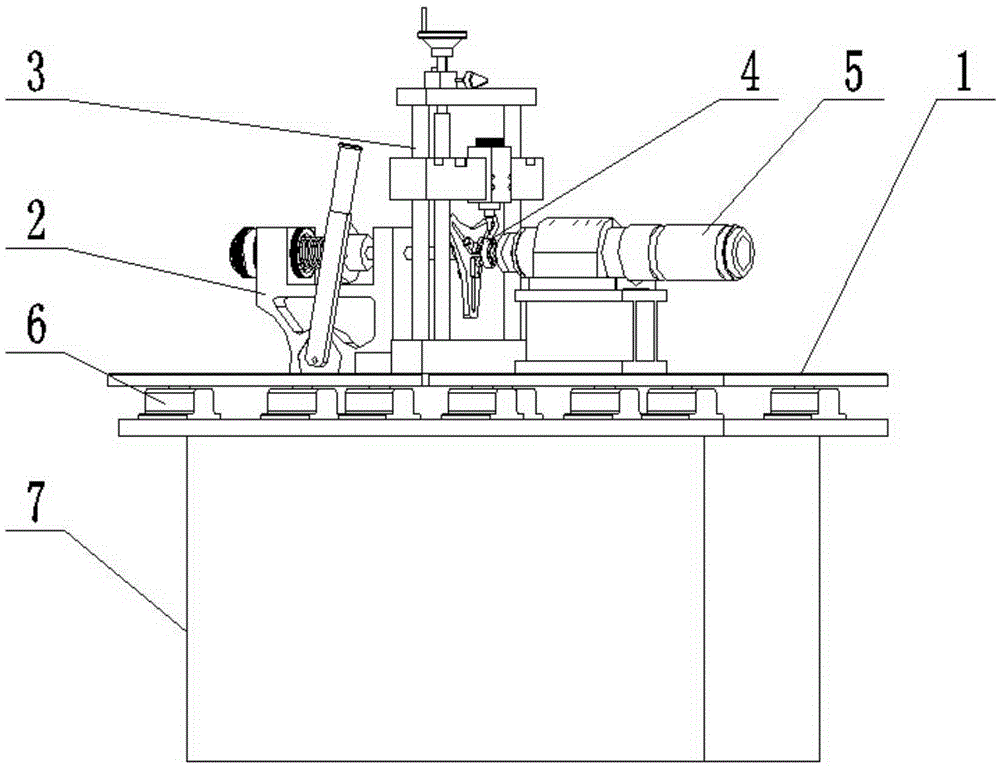

[0042] Specific implementation mode one: combine Figure 1 to Figure 22 To illustrate this embodiment, the method described in this embodiment includes the following steps:

[0043]Step 1: Build a high-speed vibration measuring instrument for rolling bearings: build a high-speed vibration measuring instrument for rolling bearings, build a high-speed vibration measuring instrument for rolling bearings according to the construction accuracy requirements of standard bearing measuring instruments for rolling bearings, and expand the speed of the standard vibration measuring instrument for rolling spindles on this basis range, using high-performance acceleration sensors to detect the vibration of bearings under high-speed working conditions; in this step, the speed of the rolling spindle standard vibration measuring instrument is expanded to a maximum of 60000r / min;

[0044] Step 2: Detect the high-speed vibration measuring instrument for rolling bearings: Detect the performance of...

Embodiment 1

[0058] Embodiment one: combined with attached Figure 16 This embodiment is described. This embodiment is to verify that the bearing has different vibration states at high speed and low speed, and it shows that the vibration evaluation of rolling bearings at high speed cannot use the vibration characterization at low speed. Select bearings numbered 03# and 15# in the above verification test. From the above verification test, it can be seen that the vibration of the 03# bearing is relatively large, while the vibration level of the 15# bearing is small. Perform high-speed vibration tests on a vibration measuring instrument. Depend on Figure 16 The root mean square of the bearing vibration signal changes with the speed can be clearly seen:

[0059] 1) The vibration of the bearing generally shows an increasing trend with the increase of the bearing speed, especially when the speed exceeds a certain level, the root mean square value will increase rapidly;

[0060] 2) The 3# bea...

Embodiment 2

[0061] Embodiment two: combined with attached Figure 17 Describe this embodiment, this embodiment is the vibration measurement of the test bearing 4 at different speeds, 6 sets are selected from the above-mentioned test bench verification test, respectively 03#, 06#, 08#, 16#, 11#, 15# #Bearing, carry out bearing vibration tests at different speeds on a high-speed bearing vibration measuring instrument, use the root mean square RMS to characterize the vibration of the bearing, and the analysis results are shown in the figure. The root mean square value reflects the overall energy of the vibration signal, and the larger the root mean square value, the greater the vibration. by attaching Figure 17 It can be seen that as the speed increases, the RMS values of the six sets of bearings all increase, and the vibrations all increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com