Weaving monitoring system

A monitoring system and ERP system technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as low data accuracy, reduce management costs, enhance core competitiveness, and reduce production Effects of schedule and risk of product quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

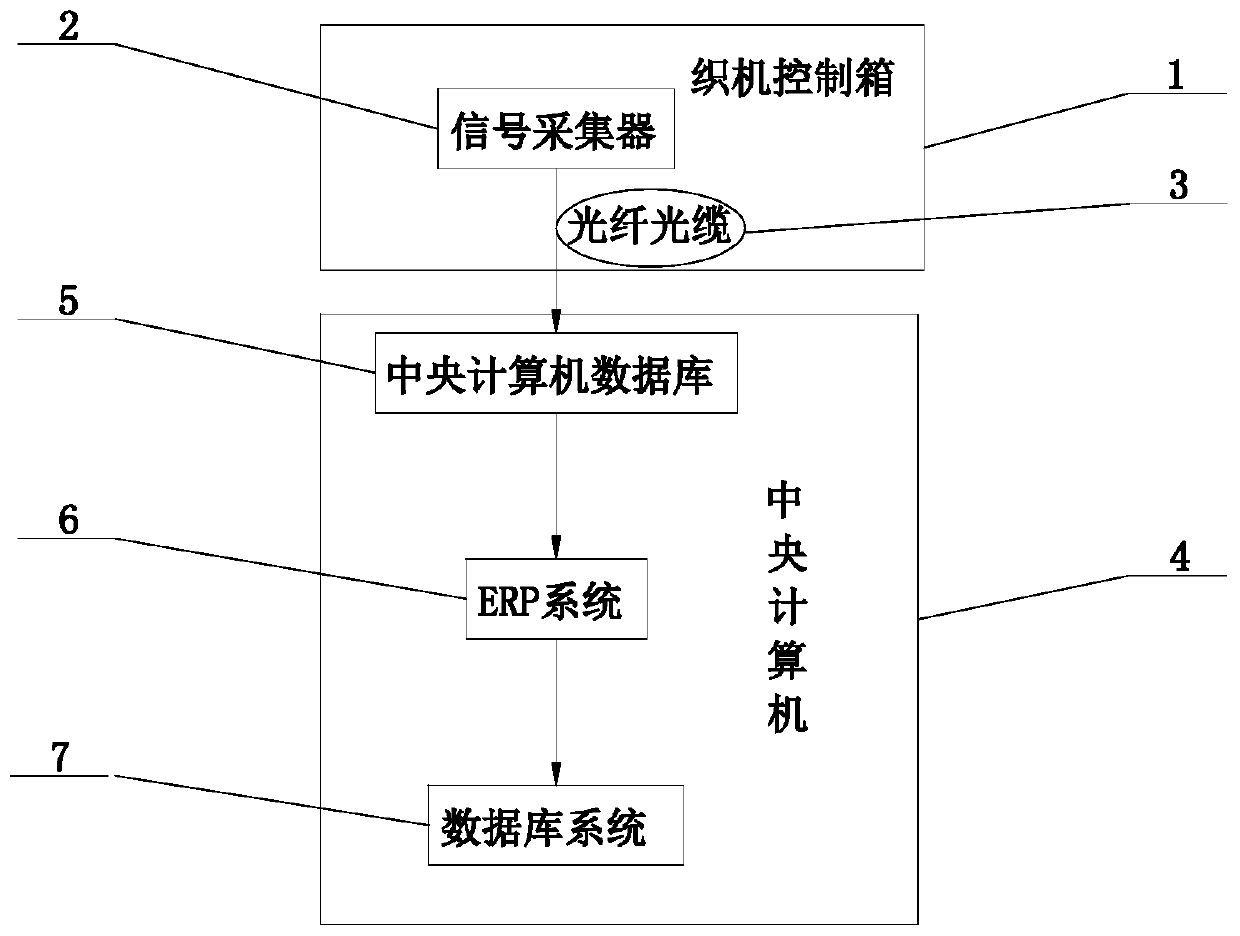

[0026] see figure 1 As shown, the technical solution adopted in this specific embodiment is: it includes loom control box 1, signal collector 2, optical fiber cable 3, central computer 4, central computer database 5, ERP system 6, database system 7, in each The loom control box 1 is equipped with a signal collector 2, and each of the loom control boxes 1 is also equipped with an optical fiber cable 3, and the central computer 4 is provided with a central computer database 5, an ERP system 6, a database System 7, the signal collector 2 is connected to the central computer database 5 through the optical fiber cable 3, the central computer database 5 is connected to the ERP system 6, and the ERP system 6 is connected to the database system 7.

[0027] The flow of a weaving monitoring system is as follows:

[0028] Step 1, signal collection: the signal collector 2 collects relevant information signals of the loom;

[0029] Step 2, signal processing: in order to realize the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com