Novel ring-on-ring biaxial bending strength test clamp and positioning cover thereof

A bending strength and testing fixture technology, applied in the direction of using a stable bending force to test material strength, strength characteristics, measuring devices, etc. The effect of preventing errors, fast alignment, and preventing sputtering everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

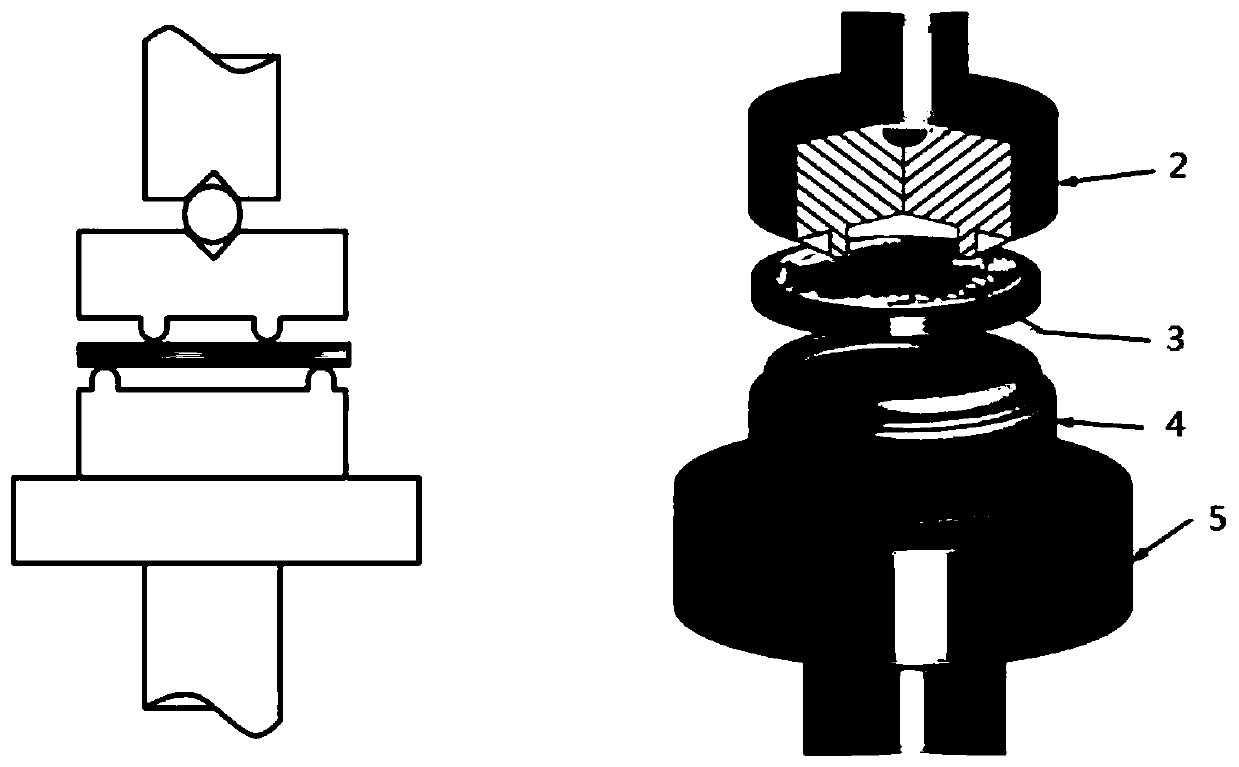

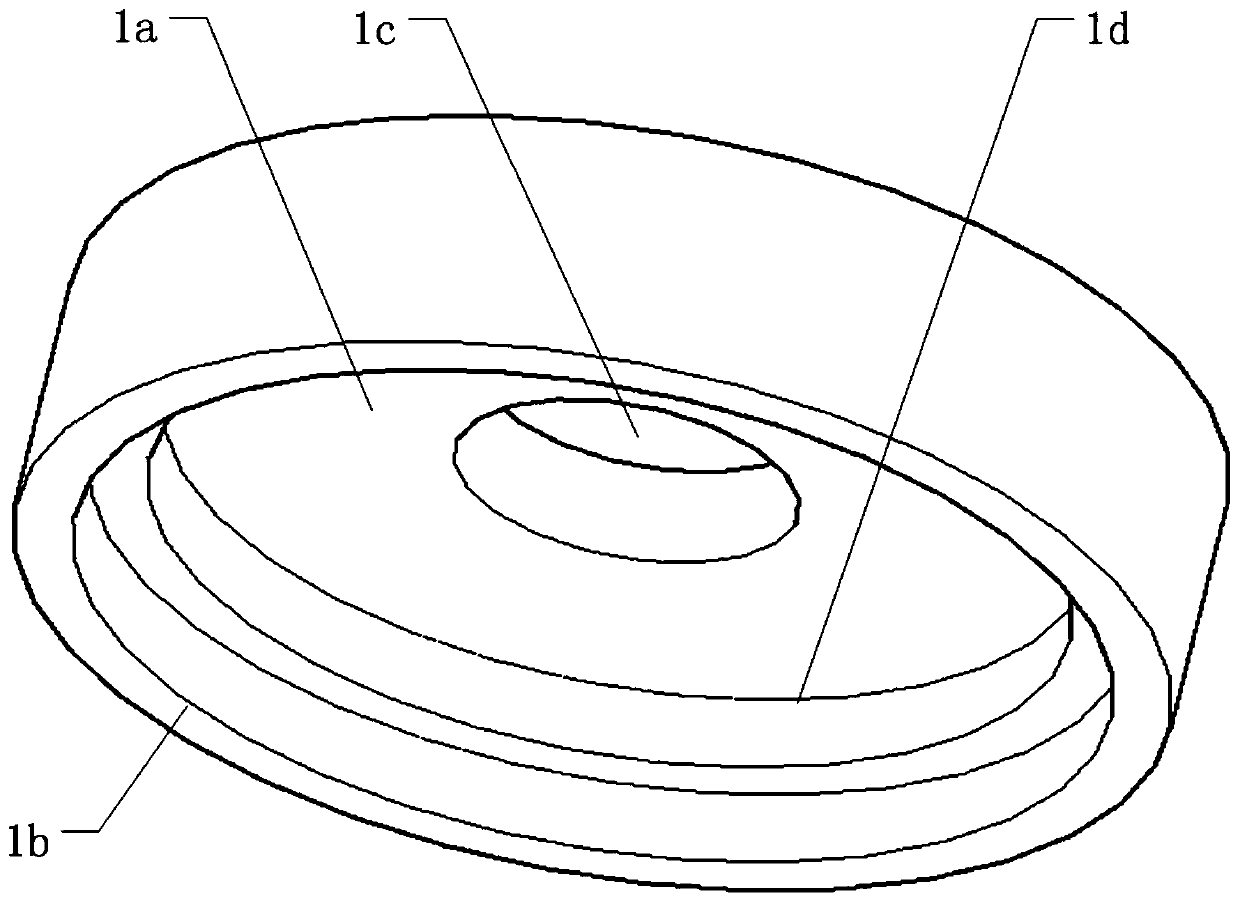

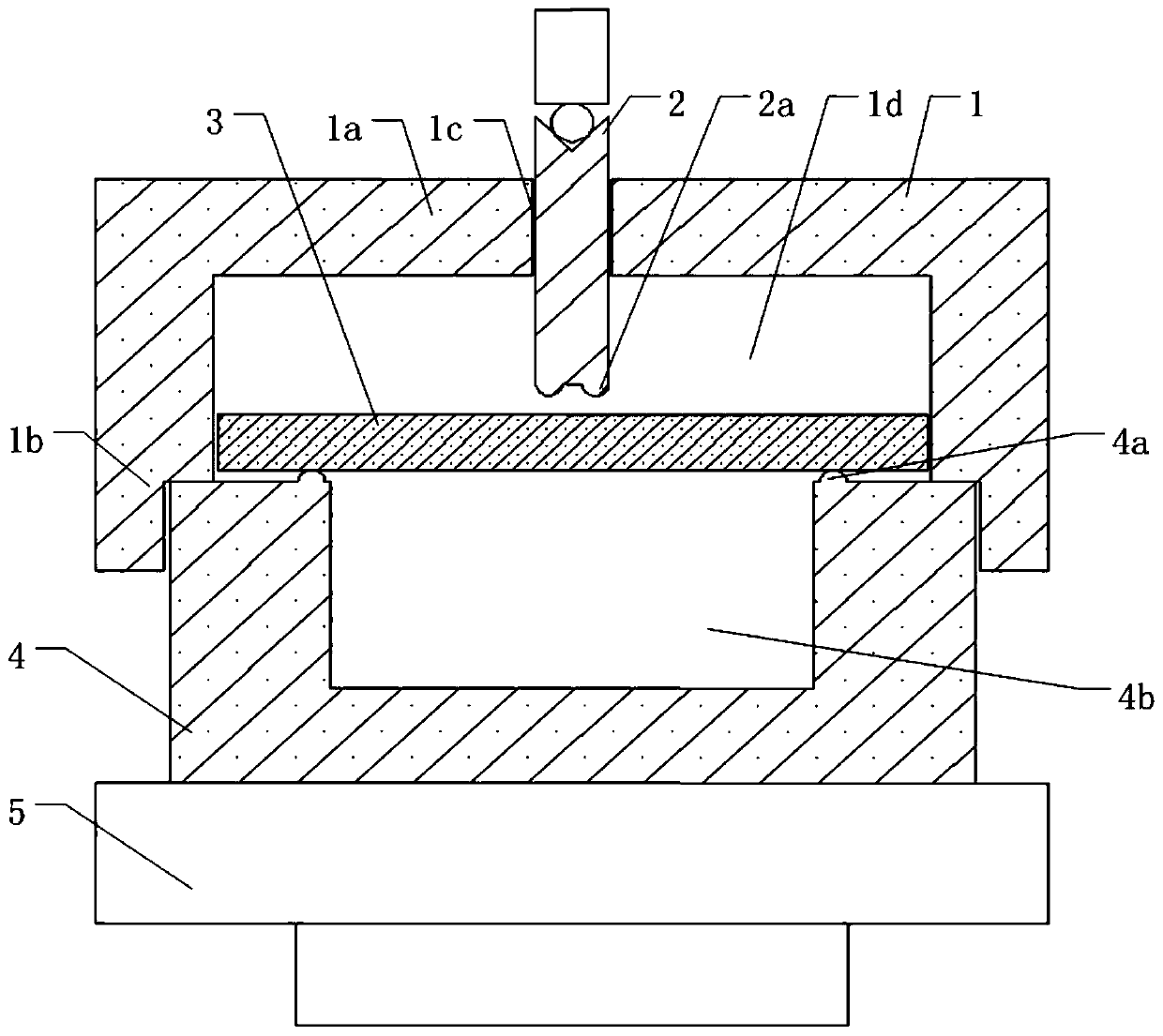

[0034] Such as figure 2 As shown, this embodiment discloses a positioning cover for a ring-on-ring biaxial bending strength test fixture, and the ring-on-ring biaxial bending strength test fixture includes a loading ring installation part with a loading ring 2a installed at the bottom 2. The support ring installation part 4 of the support ring 4a is installed on the top, and the two installation parts are arranged opposite to each other. The bottom of the positioning cover 1 is provided with an accommodating cavity 1d for accommodating the test sample 3, and the size of the accommodating cavity 1d corresponds to the test sample 3, so that the test sample 3 cannot move left and right after being placed in the accommodating cavity 1d. The bottom of the positioning cover 1 is designed with a mounting mechanism 1b for mounting the positioning cover 1 on the mounting part 4 of the support ring. Extending the direction of the top 1a of the positioning cover at the top of the chamb...

Embodiment 2

[0037]This embodiment discloses a novel ring-on-ring biaxial bending strength test fixture, which includes a loading ring installation part 2, a loading ring 2a, a support ring installation part 4, a support ring 4a and a positioning cover 1, and a loading ring installation part 2 is set opposite to the support ring installation part 4, the loading ring 2a is installed on the bottom of the loading ring installation part 2, the support ring 4a is installed on the top of the support ring installation part 4, and the positioning cover 1 is installed on the top of the support ring installation part 4 through the installation mechanism 1b. On the positioning cover 1, there is a channel 1c that allows the loading ring installation part 2 to pass through. The size of the channel 1c corresponds to the loading ring installation part 2. The loading ring installation part 2 is arranged in the channel 1c. The position of the channel 1c is designed It is: when the loading ring mounting part...

Embodiment 3

[0039] This embodiment discloses a novel ring-on-ring biaxial bending strength test fixture, which includes a loading ring installation part 2, a loading ring 2a, a support ring installation part 4, a support ring 4a and a positioning cover 1. The loading ring 2a is relatively The support ring 4a has a small diameter, the support ring installation part 4 is installed on the support rod 5, the loading ring installation part 2 is arranged opposite to the support ring installation part 4, the loading ring 2a is installed in the bottom middle of the loading ring installation part 2, and the support ring 4a is installed on In the middle of the top of the support ring installation part 4 , the positioning cover 1 is arranged on the support ring installation part 4 . A mounting mechanism 1b is designed around the bottom of the positioning cover 1 for stably mounting to the surroundings of the top of the loading ring mounting part 2 . In one embodiment, the installation mechanism 1b i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com