Isolator reverse power tolerance test system and method

A technology of reverse power and test system, which is applied in the field of aerospace, can solve the problems of unreliable test results of reverse power withstand test, and achieve the effect of reliable test method and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

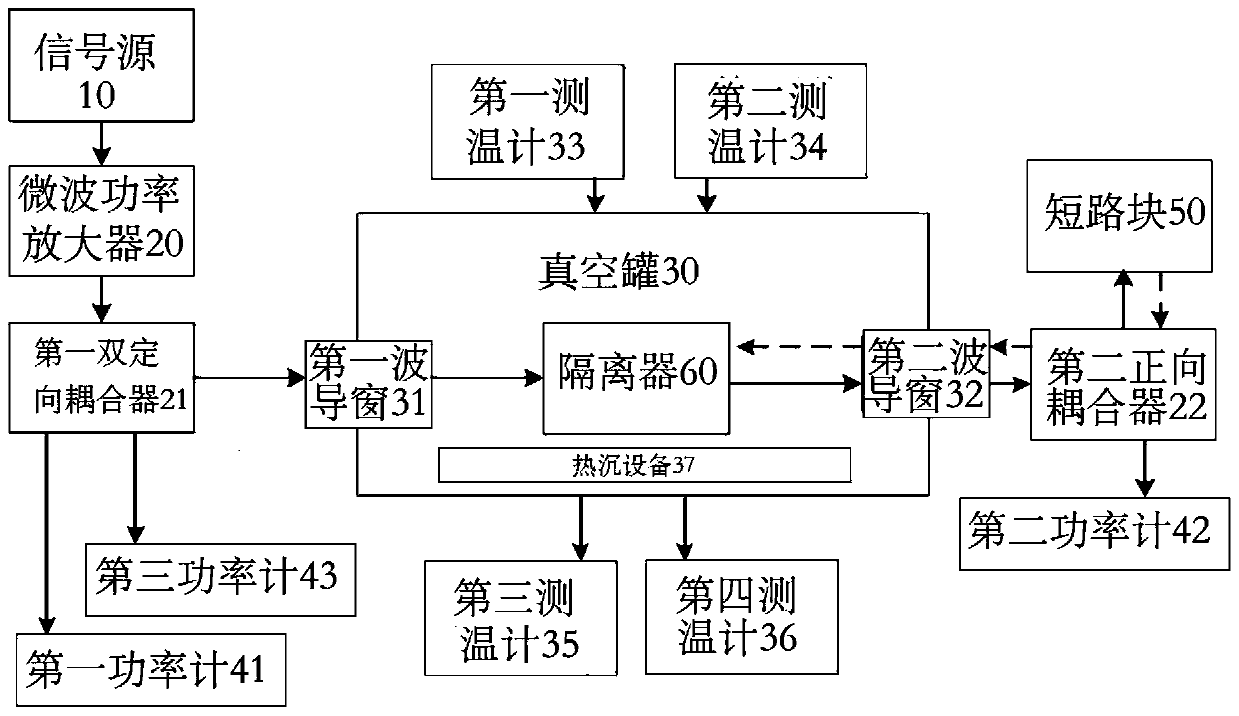

Embodiment 1

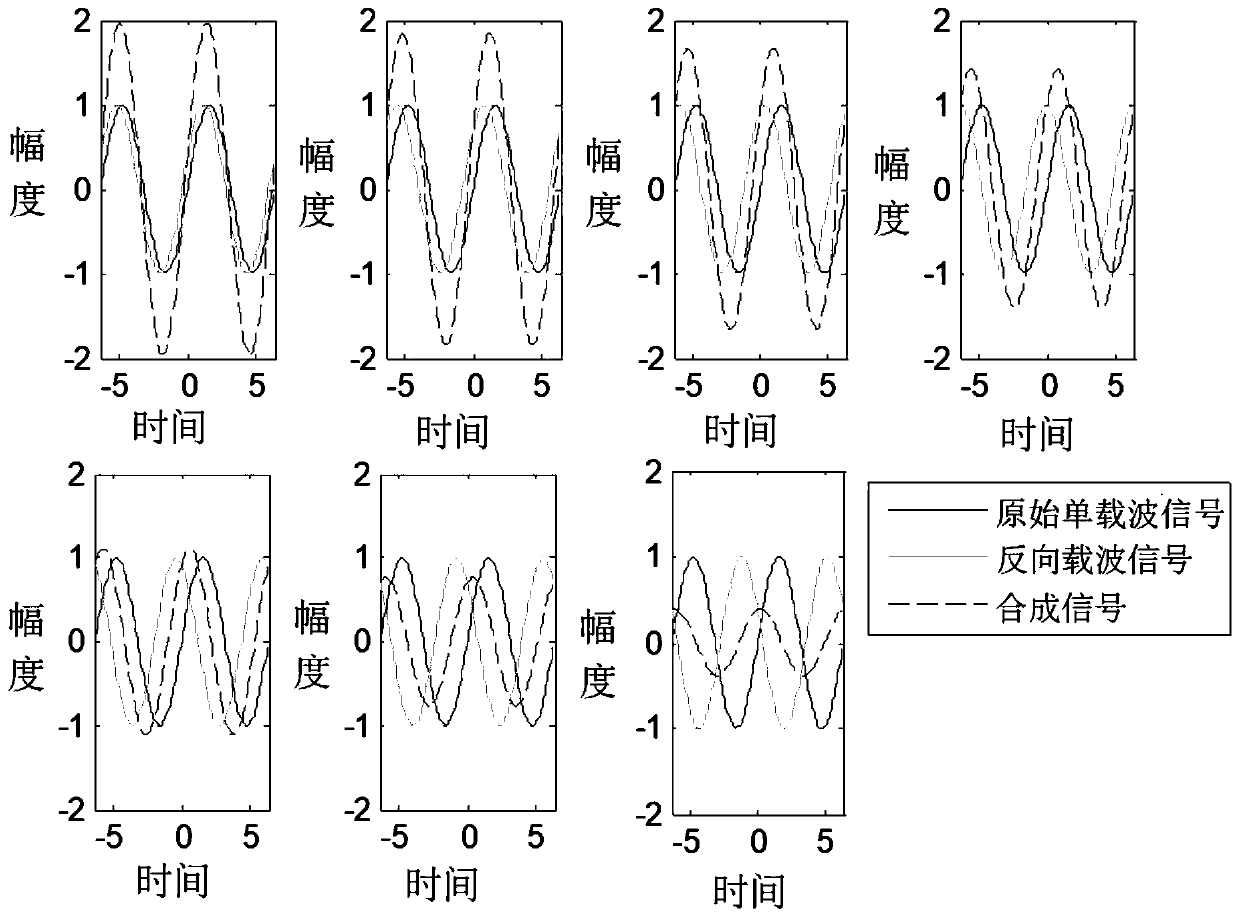

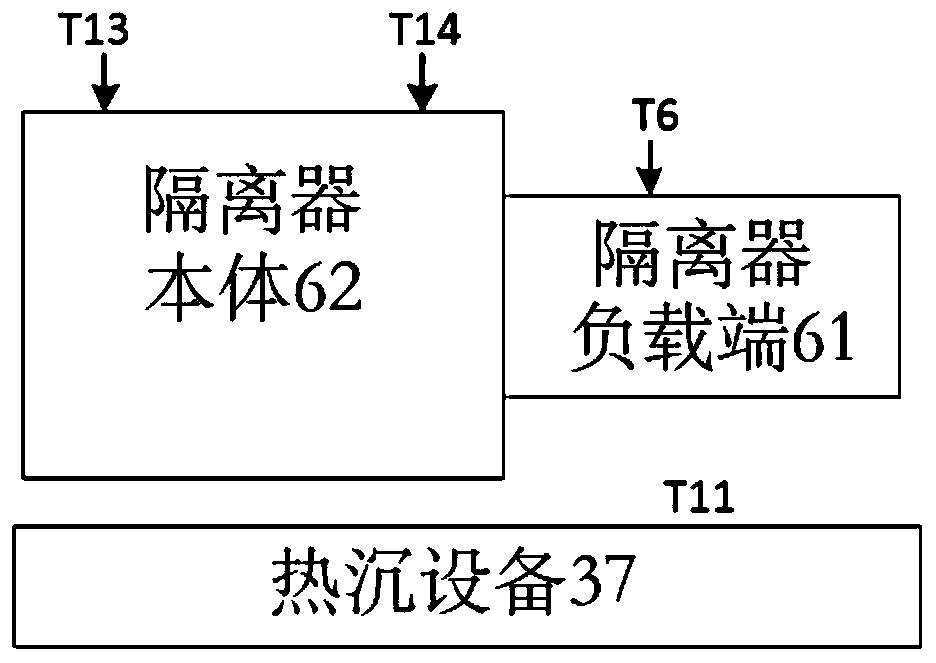

[0083] This embodiment provides an isolator reverse power withstand test system, such as figure 1 As shown, the isolator reverse power withstand test system includes a signal source 10, a microwave power amplifier 20, a first dual directional coupler 21, a second forward coupler 22, a vacuum tank 30, a first power meter 41 and Short circuit block 50, wherein: the signal source 10 sends out an original single-carrier signal; after the original single-carrier signal is amplified by the microwave power amplifier 20, it is provided to the first power by the first dual-directional coupler 21 meter 41 and the vacuum tank 30; the first power meter 41 measures the power value of the original single carrier signal to form a first power value P I The isolator 60 is placed in the vacuum tank 30; the original single-carrier signal is provided to the second forward coupler 22 through the isolator 60, and the original single-carrier signal is passed through the second The forward coupler 2...

Embodiment 2

[0106] This embodiment provides an isolator reverse power withstand test method. The isolator reverse power withstand test method includes: the signal source 10 sends out an original single-carrier signal; the original single-carrier signal is amplified by a microwave power amplifier 20 After that, it is provided to the first power meter 41 and the vacuum tank 30 through the first dual directional coupler 21; the first power meter 41 measures the power value of the original single carrier signal to form the first power value P I The isolator 60 is placed in the vacuum tank 30; the original single carrier signal is provided to the second forward coupler 22 through the isolator 60, and the original single carrier signal is passed through the second forward coupler 22; The coupler 22 is provided to the short-circuit block 50; the original single-carrier signal enters the short-circuit block 50 for delay and reverse transmission to form a reverse carrier signal, and the reverse car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com