Automobile current sensor automatic testing device

An automatic test device and current sensor technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of low efficiency, high time cost and labor cost, and achieve high test accuracy, high test efficiency, and high equipment safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

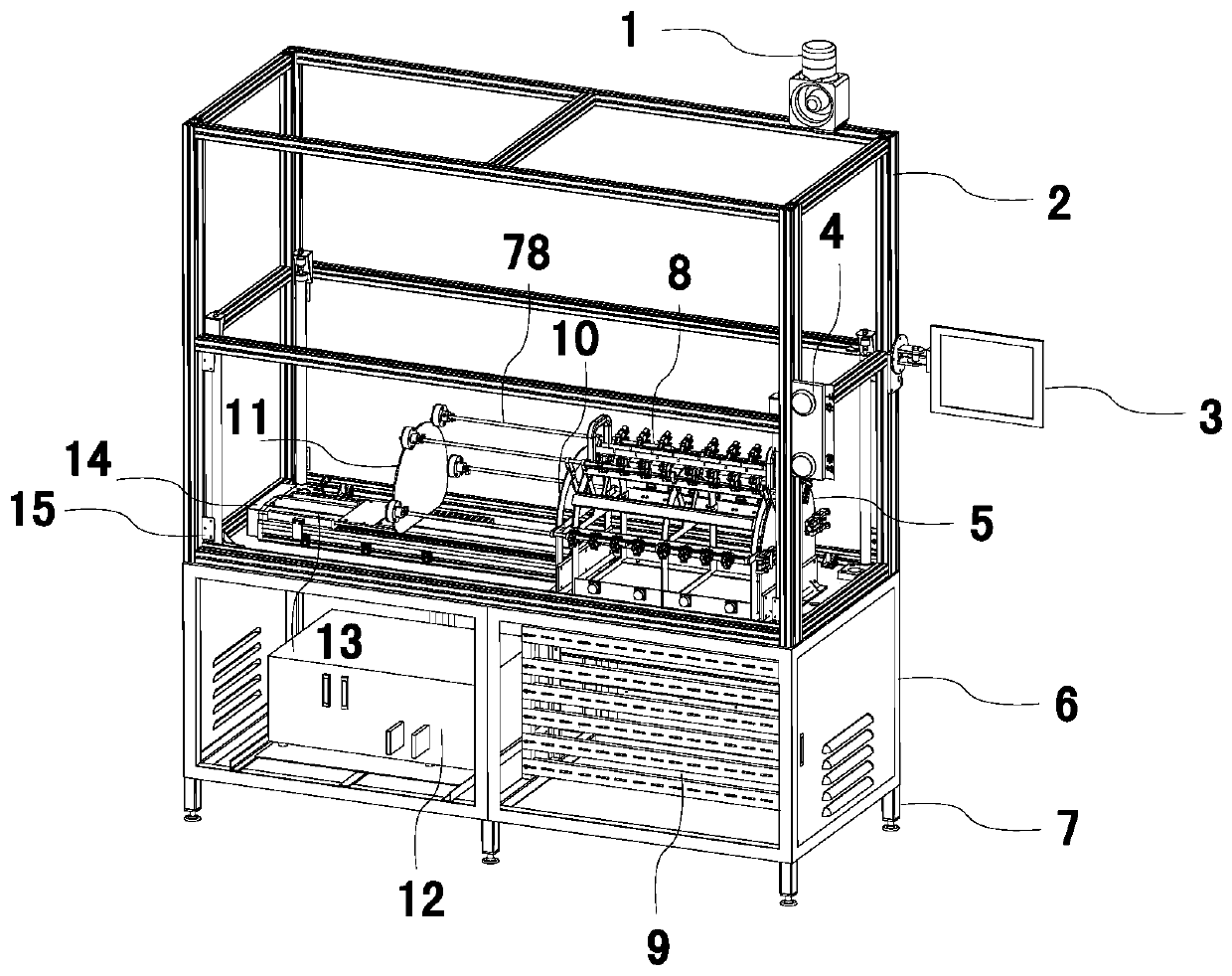

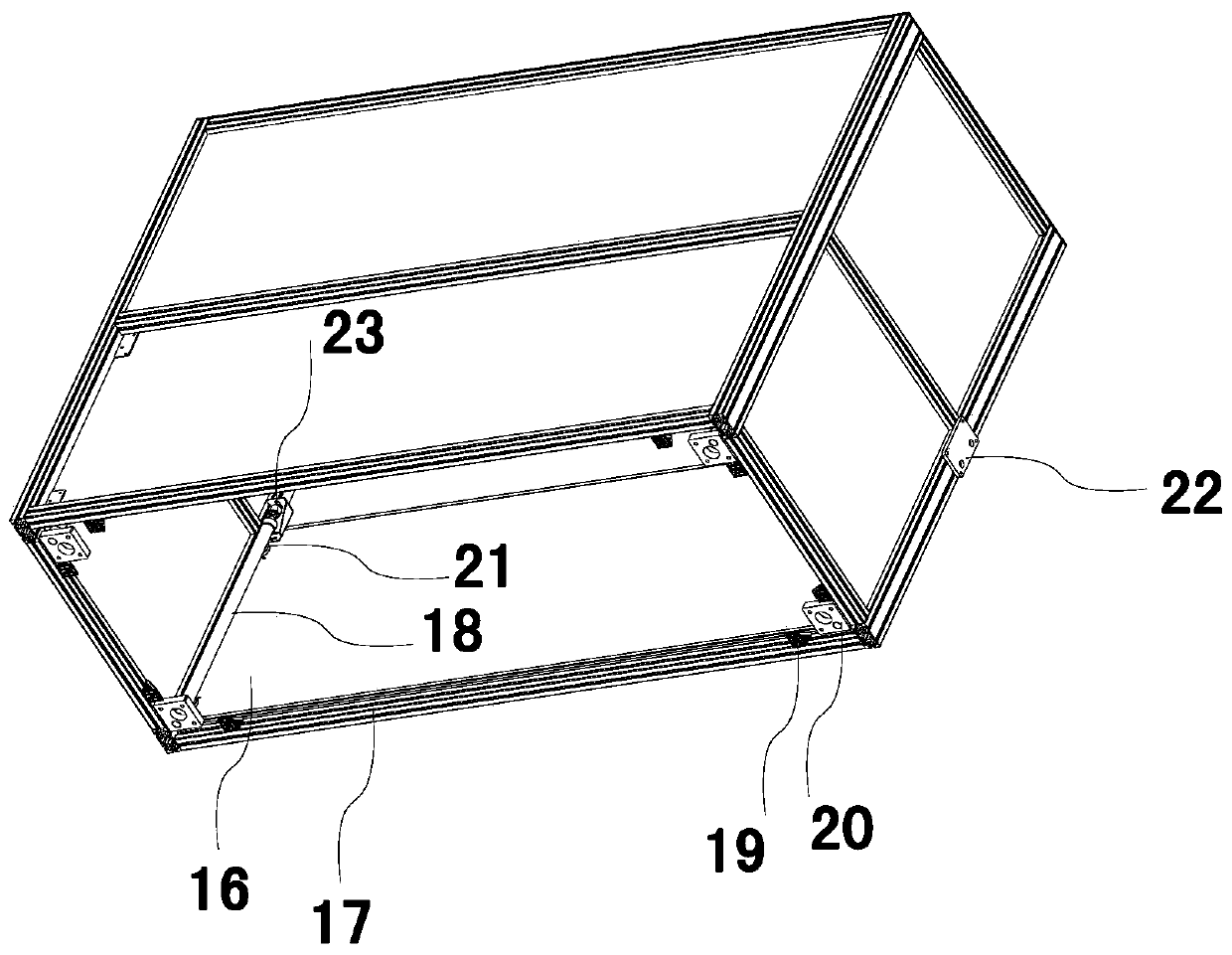

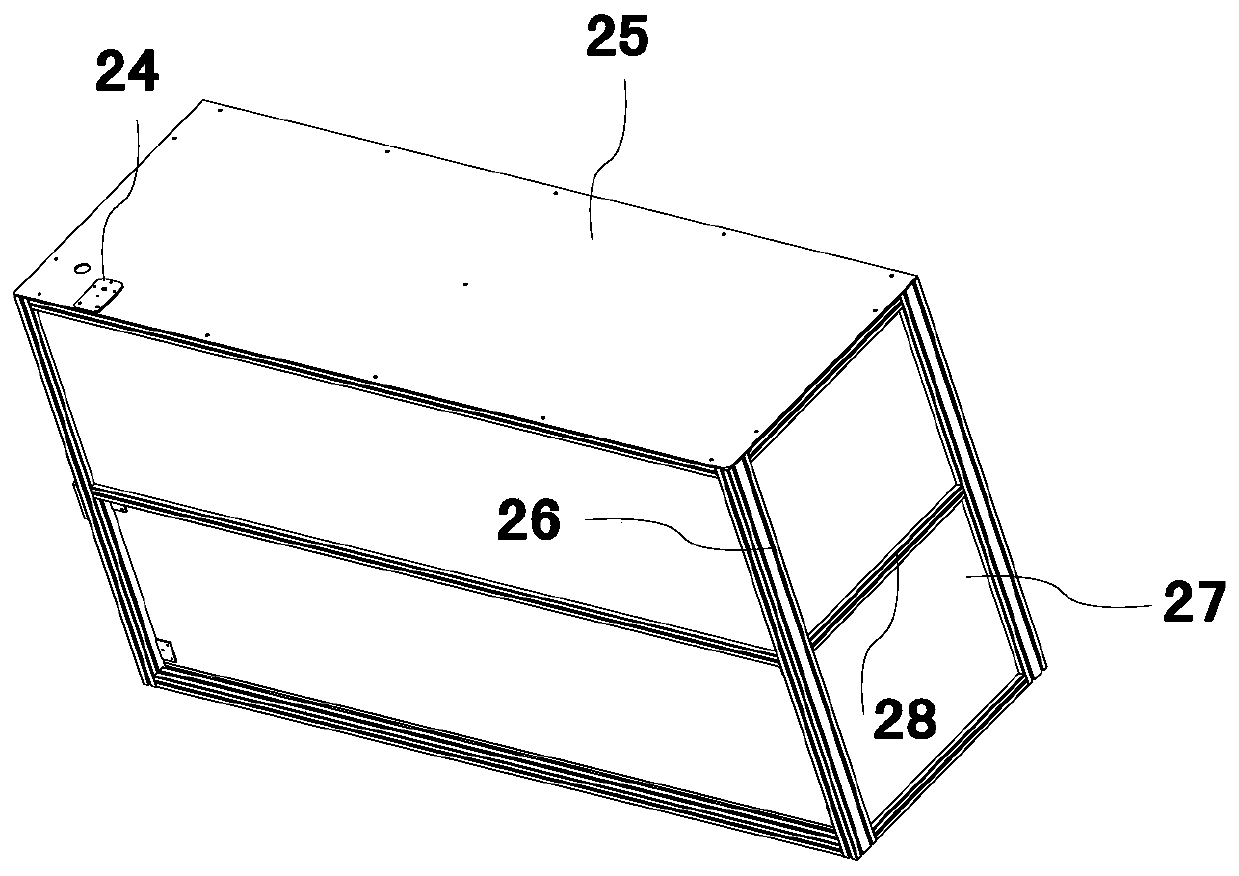

[0039] As shown in the figure, the automotive current sensor automatic test device includes an outer cover 2, a workbench assembly 6, a control module, a pneumatic control assembly 9 and a standard DC current source 12; the outer cover 2 is fixedly arranged on the workbench assembly 6; Inside the outer cover 2, on the workbench, there are a clamping assembly 5, a testing assembly 8, a guide assembly 10, an optical axis drive assembly 11, a ball screw module 13 and a servo motor 14; the pneumatic control assembly 9 and the control module are respectively fixed on the right side of the workbench assembly 6; the standard DC current source 12 is fixed on the left side of the workbench assembly 6; end; the power output end of the servo motor 14 is connected to the power input end of the ball screw module 13; the moving end of the ball screw module 13 is fixedly connected to the bottom of the optical axis drive assembly 11, so that It realizes linear reciprocating motion; the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com