Multi-sound field interfered acoustic levitation device and sound filed switching method

A technology of acoustic levitation and sound field, which can be used in measurement devices, re-radiation of sound waves, and re-radiation by use of sound waves. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

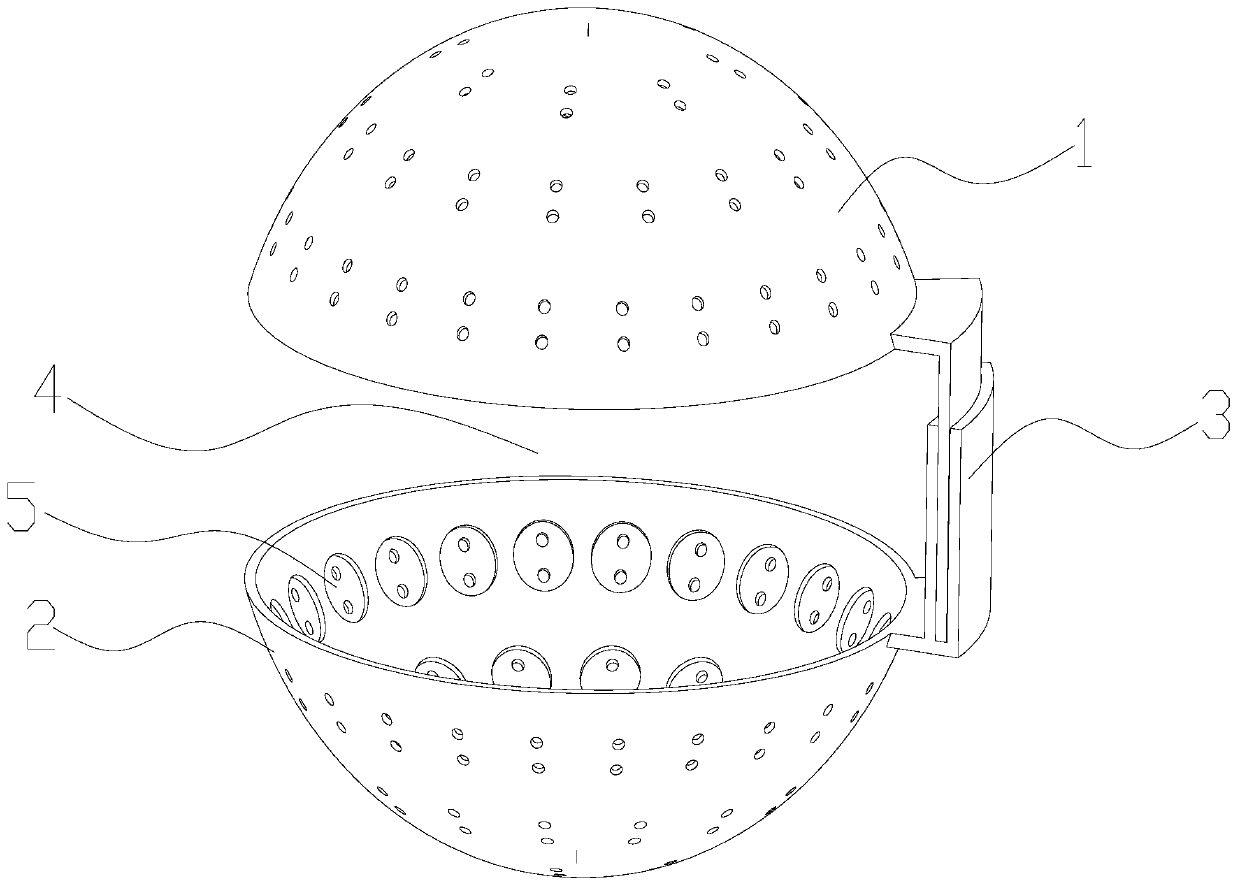

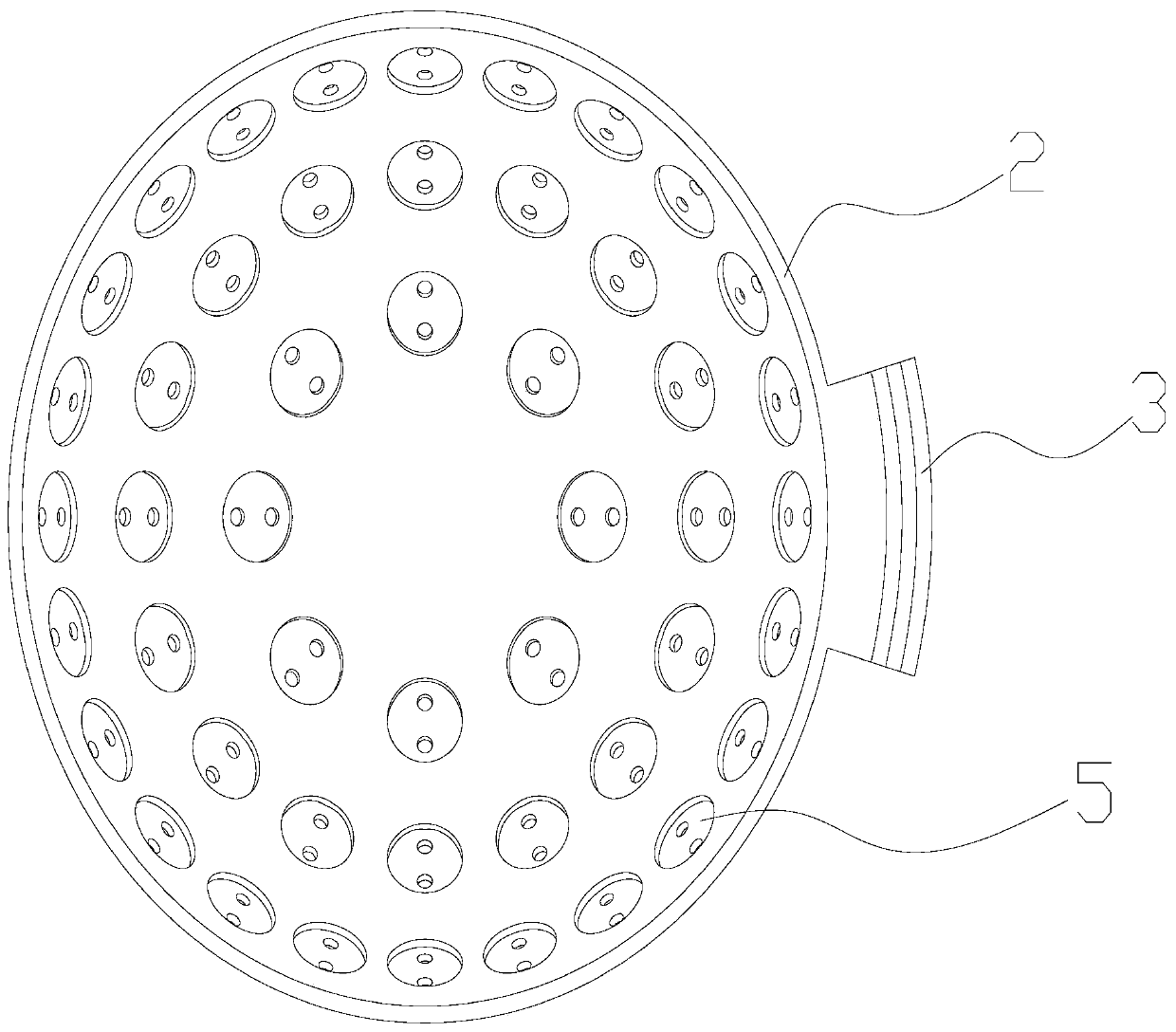

[0027] Such as figure 1 with figure 2 As shown, the present embodiment is a multi-sound field interference acoustic levitation device, including a single-chip microcomputer, a drive motor module, a power supply module, a controller, an upper casing 1, a lower casing 2, a connecting part 3 and sixteen ultrasonic emission areas;

[0028] Such as figure 1 with figure 2 As shown, the upper shell and the lower shell are in the shape of a hemispherical shell respectively, the upper shell and the lower shell are arranged opposite and parallel, the connecting part connects the upper shell and the lower shell, and the upper shell, the lower shell and the connecting part 3D printing is adopted, and the upper shell and the lower shell are arranged at intervals to form a suspension space 4, and a plurality of mounting holes 5 are respectively provided on the upper shell and the lower shell.

[0029] Such as figure 1 with figure 2 As shown, eight ultrasonic emitting areas are distr...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the above-mentioned multi-sound field interference acoustic levitation device is used as a switching method of the vortex field. The upper casing is energized, and the initial phases of the eight ultrasonic emission areas on the upper casing are gradually shifted toward the clockwise direction. Incremental, for example, the initial phases of ↑Ⅰ, ↑Ⅱ, ↑Ⅲ, ↑Ⅳ, ↑Ⅴ, ↑Ⅵ, ↑Ⅶ, ↑Ⅷ are 0, Π / 4, Π / 2, 3Π / 4, Π, 5Π / 4 . The initial phases in the clockwise or counterclockwise direction gradually increase, for example, the initial phases of ↓Ⅰ, ↓II, ↓Ⅲ, ↓IV, ↓Ⅴ, ↓Ⅵ, ↓Ⅶ, ↓Ⅷ are 0, Π / 4, Π / 2, 3Π / 4, Π, 5Π / 4, 3Π / 2, 7Π / 4, the sum of the initial phase changes of the eight ultrasonic emission areas on the lower shell is 2π, that is, a topological charge For a sound field with a degree of 1, when the initial phase change direction of the eight ultrasonic emission areas on the lower shell is the same as the initial phase change dire...

Embodiment 3

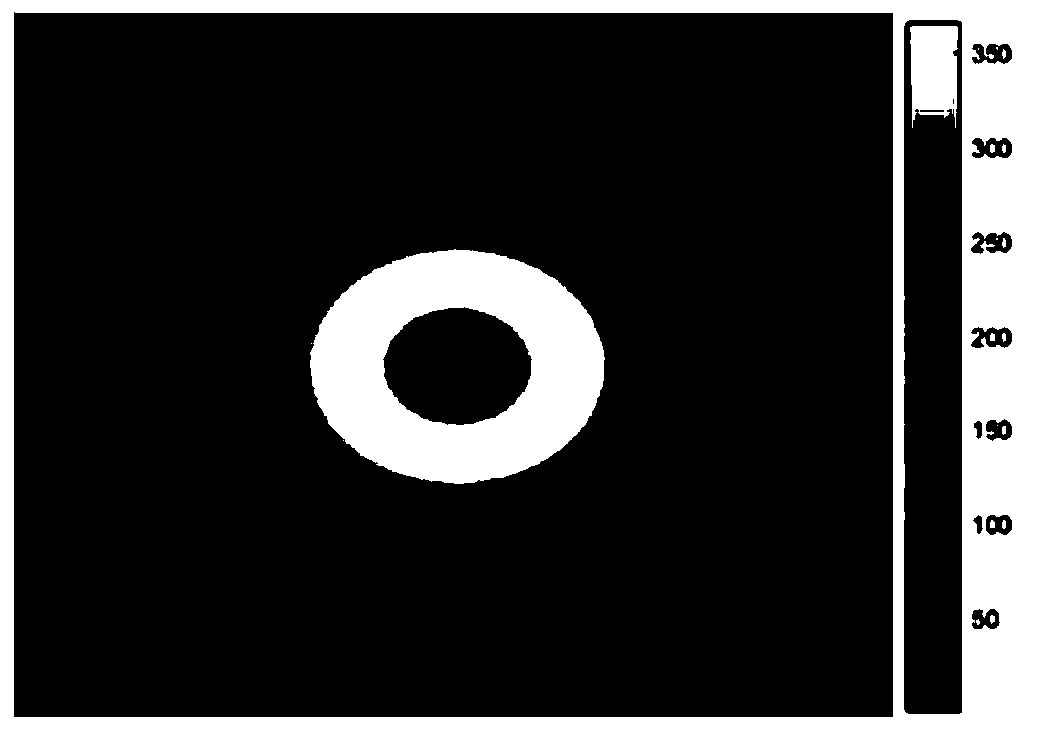

[0043] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the two points A and B represent two point sound sources with opposite phases. The length of the AC line segment is a, the length of the BC line segment is b, and the length of OC is r. When a-b=λ / 2 is satisfied, and λ is the wavelength of the sound wave, C The point is the first-level main-level bright fringe, and OC can be approximately regarded as 0 sound pressure. Through this principle, the phase difference between adjacent ultrasonic emission areas is π, and a large central zero-sound pressure area can be constructed by arranging in a circle to suspend large objects.

[0044] Set the initial phases of the eight ultrasonic emitting areas on the upper shell to gradually increase by π in the clockwise direction, for example, the initial phases of ↑Ⅰ, ↑Ⅱ, ↑Ⅲ, ↑Ⅳ, ↑Ⅴ, ↑Ⅵ, ↑Ⅶ, ↑Ⅷ 0, π, 2π, 3π, 4π, 5π, 6π, 7π, the sum of the initial phase changes of the eight ultrasonic emission area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com