Iron-nitrogen double-doped hollow porous carbon sphere nano material and preparation method thereof

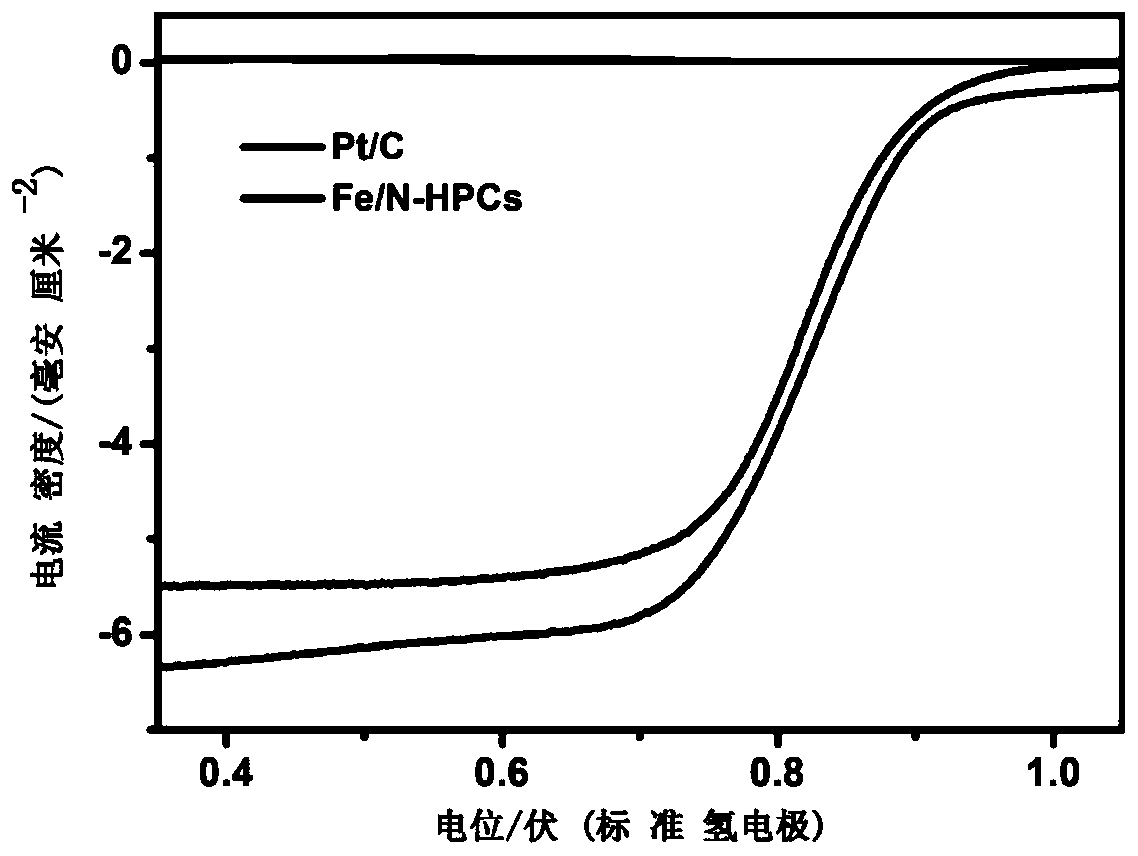

A nano-material and double-doping technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of uneven dispersion, inability to increase specific surface area, and poor morphology of nitrogen-doped composite materials. Control and other issues, to achieve the effect of increasing the specific surface area, excellent electrocatalytic performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

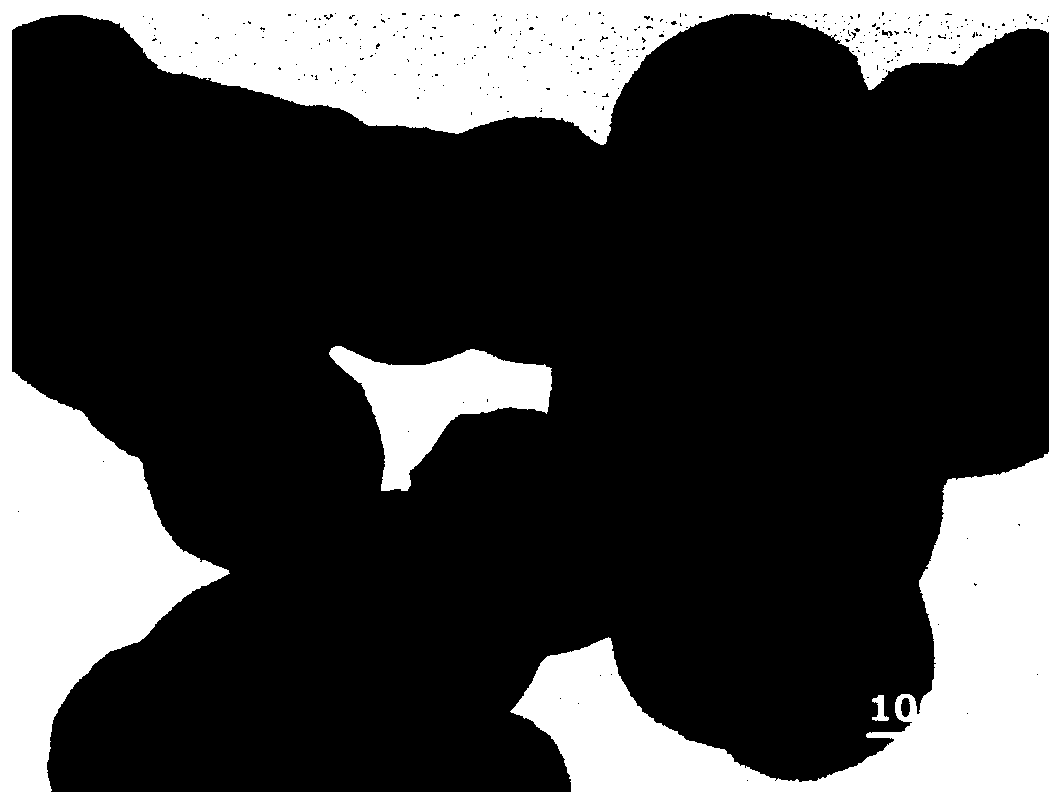

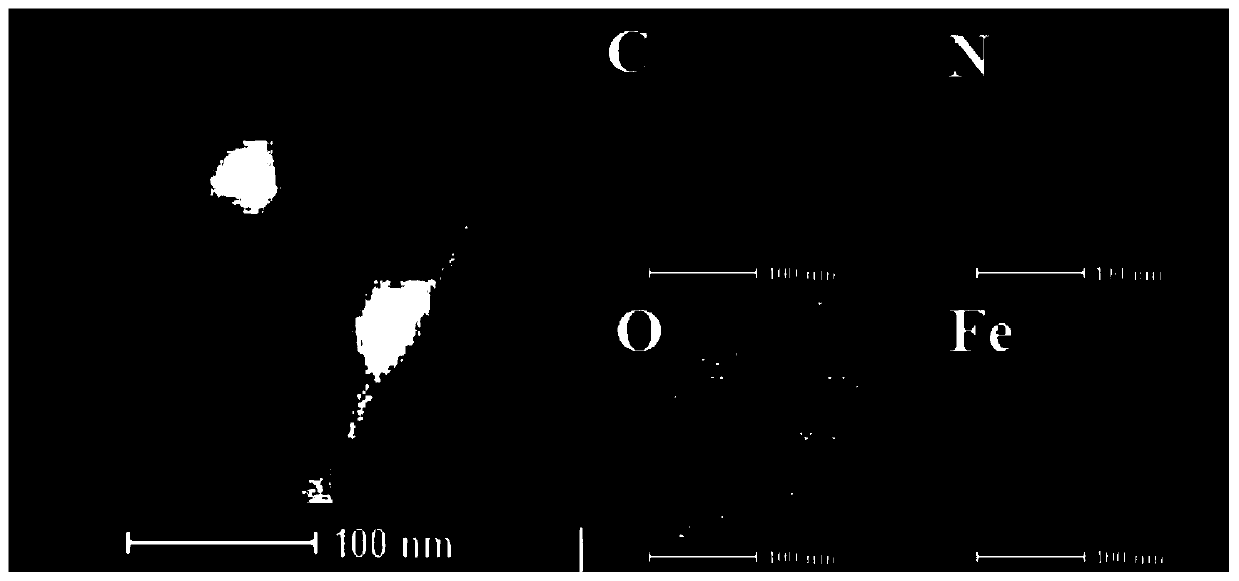

Image

Examples

preparation example Construction

[0029] The present invention firstly provides a method for preparing a hollow porous carbon sphere nanomaterial doped with iron and nitrogen, which specifically includes the following steps:

[0030] Step 1. Preparation of SiO 2 Core-shell precursor

[0031] Preparation of SiO 2 Nanosphere mixed solution, adding dopamine and F127 to the above mixed solution, stirring and reacting to obtain SiO 2 Core-shell structure precursor solution; the reaction temperature is preferably room temperature, and the reaction time is preferably 10-15 hours.

[0032] The source of the F127 is commercially available, specifically Pluronic F127.

[0033] SiO 2 The nanospheres can be prepared by the existing preparation method, for details, refer to [W.Stober, A.Fink, E.Bohn, E.J.Colloid Interface Sci. 1968, 26, 62-69].

[0034] For example, SiO 2 The preparation method of the nanosphere mixed solution is as follows: dissolving ammonia water and tetraethyl orthosilicate in the mixed solution ...

Embodiment 1

[0043] 1. Preparation of SiO 2 Core-shell precursor

[0044]1) Add 1.25ml of ammonia water and 1.40ml of ethyl orthosilicate to the mixed solution of ethanol and deionized water, stir evenly to obtain SiO-containing 2 Mixture of nanospheres;

[0045] 2) Add 0.30g dopamine and 0.15g F127 to the above solution, and stir at room temperature for 12 hours;

[0046] 2. Preparation of Fe / N double-doped hollow porous carbon nanomaterials

[0047] 1) Weigh 0.010g of iron acetylacetonate and dissolve it in ethanol, add it to the above solution, and stir at room temperature for 12 hours;

[0048] 2) centrifuging the reacted solution, washing with ethanol several times, and drying to obtain a solid product;

[0049] 3) Put the above solid product into a quartz boat, program the temperature up to 800°C under the protection of nitrogen, and heat-treat for 2 hours to obtain the intermediate product;

[0050] 4) Put the intermediate product into a 5wt.% hydrofluoric acid solution and etc...

Embodiment 2

[0056] 1. Preparation of SiO 2 Core-shell precursor

[0057] 1) Add 1.40ml of ammonia water and 1.20ml of ethyl orthosilicate to the mixed solution of ethanol and deionized water, stir evenly to obtain SiO-containing 2 Mixture of nanospheres;

[0058] 2) Add 0.20 g of dopamine and 0.15 g of F127 to the above solution, and stir at room temperature for 15 hours;

[0059] 2. Preparation of Fe / N double-doped hollow porous carbon nanomaterials

[0060] 1) Weigh 0.015g of iron acetylacetonate and dissolve it in ethanol, add it to the above solution, and stir at room temperature for 15 hours;

[0061] 2) centrifuging the reacted solution, washing with ethanol several times, and drying to obtain a solid product;

[0062] 3) Put the above solid product into a quartz boat, program the temperature up to 800°C under the protection of nitrogen, and heat-treat for 2 hours to obtain the intermediate product;

[0063] 4) Put the intermediate product into a 5wt.% hydrofluoric acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com