Double-core overall breathable brick, manufacturing method thereof and steel ladle bottom masonry method

A technology of breathable bricks and core bricks is applied in the field of ladle bottom masonry and double-core integral breathable bricks. , the effect of increasing the effective use length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

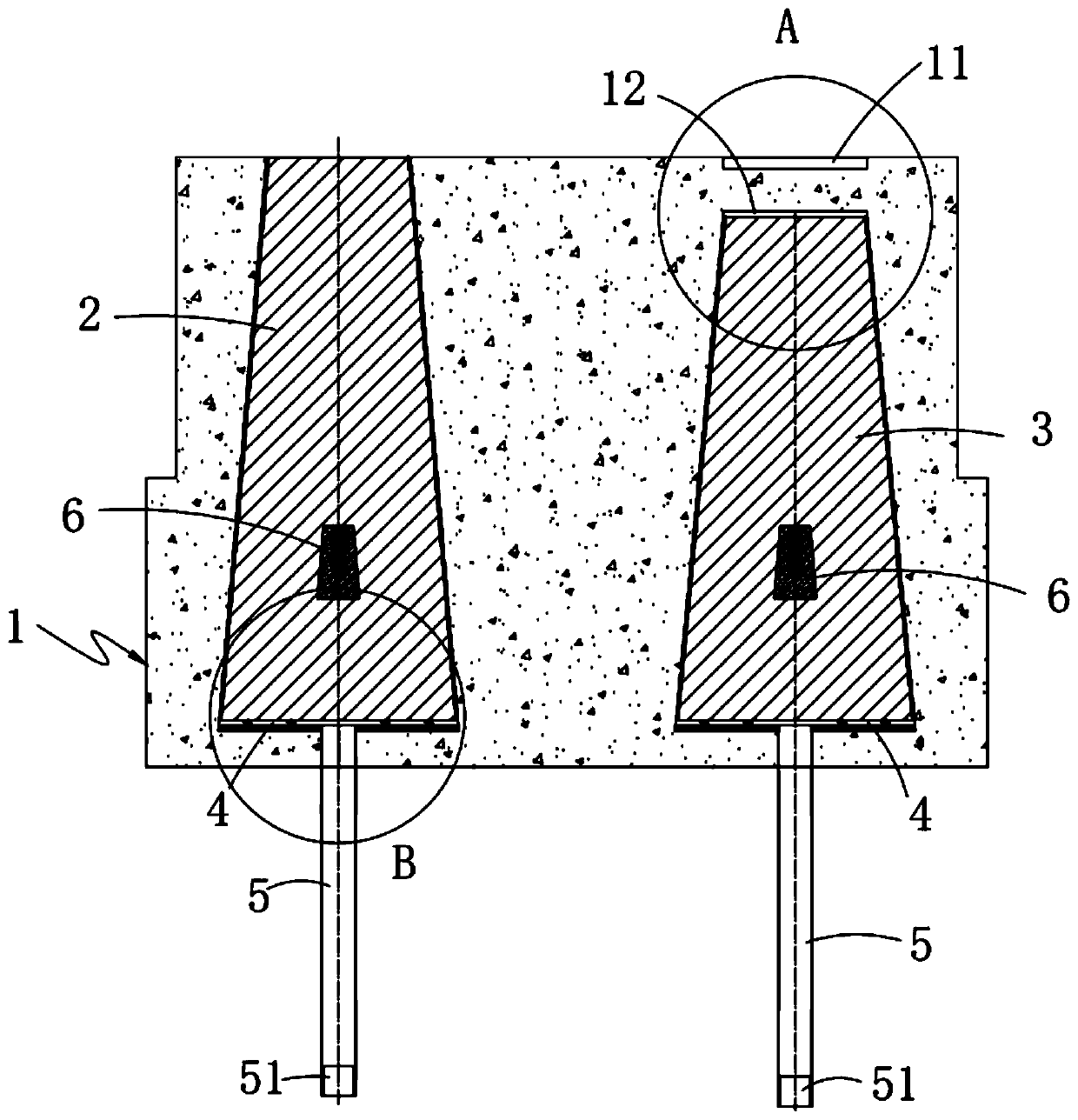

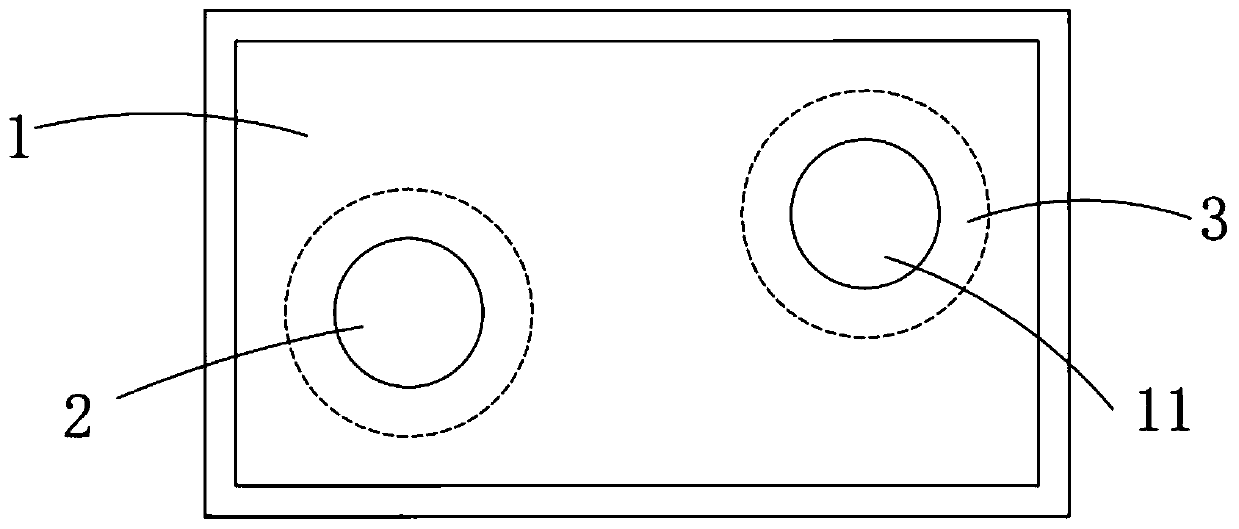

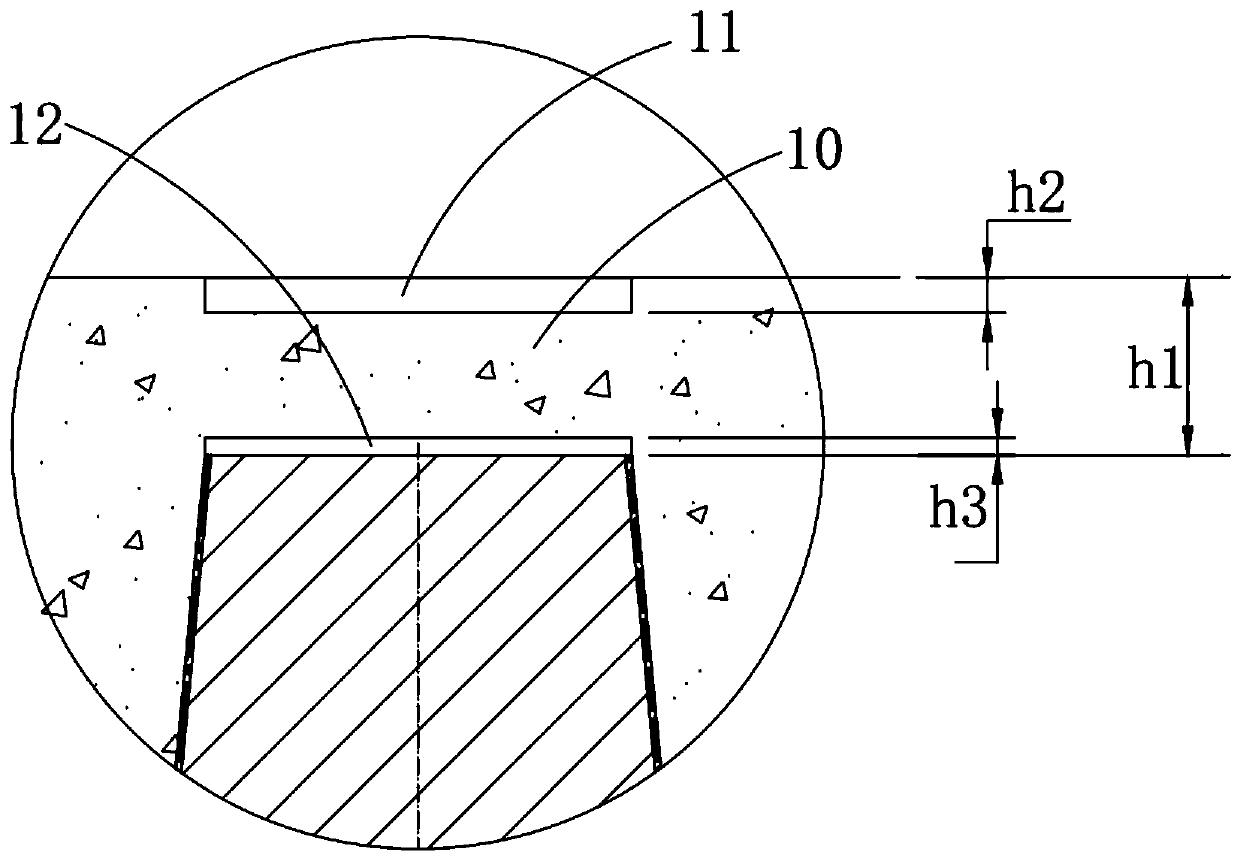

[0054] The invention provides a double-core integral air permeable brick, such as Figure 1-4 As shown, including a block 1, the block 1 is provided with a first core brick 2 and a second core brick 3, the upper end of the second core brick 3 is located below the upper end of the first core brick 2 and the second The upper end of the core brick 3 is covered by the seat brick 1; the part of the seat brick 1 covering the upper end of the second core brick 3 is a reserved layer 10, and a liquid storage tank is opened on the upper surface of the reserved layer 10 11, an empty layer 12 is provided between its lower surface and the upper end of the second core brick 3.

[0055] It is worth noting that by setting the liquid storage tank 11, since there is molten steel in the liquid storage tank 11, it will be brighter than the surrounding area when observed, so when the first core brick 2 reaches the service life, it can be used according to the storage liquid. The position of the g...

Embodiment 2

[0069] The present invention also provides a method for directly prefabricating a double-core integral air-permeable brick, which includes the following manufacturing steps:

[0070] Step 1: After the prefabricated first core brick and the conical surface of the second core brick are evenly coated with refractory mud, they are placed in the seat brick mold with the center of the seat brick mold as the center of symmetry, and the upper end of the second core brick The bottom is 50mm lower than the block mold, and a combustible material with a thickness of 3-5mm is placed in the corresponding air chamber, and the strip-shaped organic matter is fixed on the combustible material to distribute it evenly;

[0071] Step 2, laying combustibles with a thickness of 5mm on the upper end of the second core brick, filling the prefabricated material into the block mold and vibrating to form the block;

[0072] Step 3, pre-embed a circular mold assembly matching the shape of the upper end of...

Embodiment 3

[0075] Taking the installation of Taigang 180t stainless steel clad double-core overall breathable brick as an example, the specific masonry steps are as follows:

[0076] Such as Figure 8As shown, an integral air brick and two double-core integral air bricks described in the above scheme are built with corundum castables in the impact area of molten steel at the bottom of the ladle, where the integral air brick is a single-core air brick, and two The double-core integral breathable bricks are respectively double-core integral breathable brick a and double-core integral breathable brick b. Single-core breathable bricks, double-core integral breathable bricks a and double-core integral breathable bricks b are all used in the non-impact area of molten steel at the bottom. Castable masonry refractory bricks; it should be noted that the single-core breathable brick, the double-core integral breathable brick a and the double-core integral breathable brick b are distributed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com