Cooling circulation system and control method thereof

A technology of circulation system and control method, which is applied to cooling fluid circulation devices, coolers, household refrigeration devices, etc., can solve the problems of rough control method and more energy waste, so as to reduce work burden, ensure work efficiency, and control finely. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

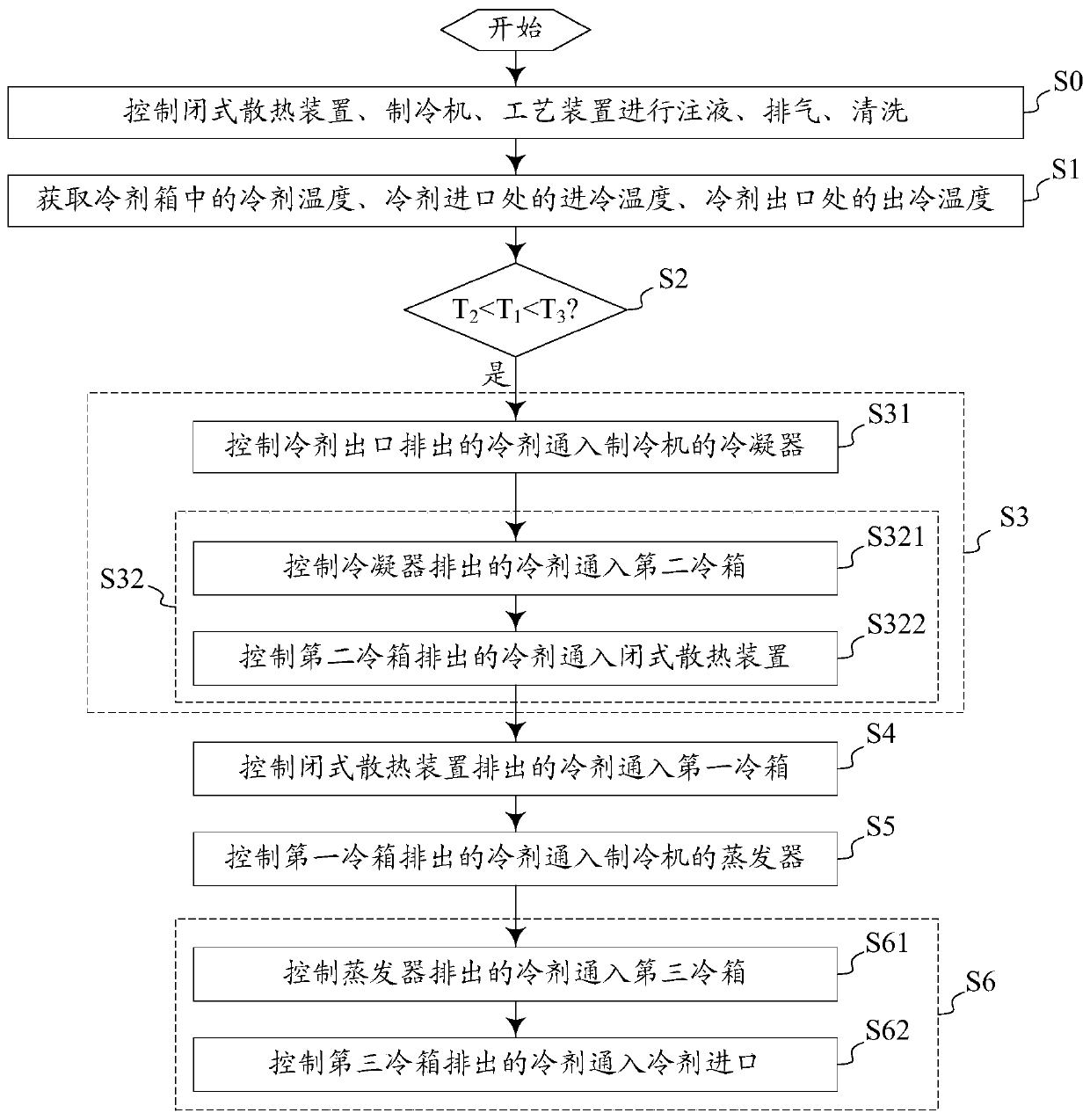

[0057] For the process side, once the process device 4 is determined, the inlet cooling temperature T of the refrigerant inlet 41 2 , the cooling temperature T of the refrigerant outlet 42 3 are determined, in an exemplary scheme, T 2 can be 12°C, T 3 It can be 18°C. If the ambient temperature is low, only the natural cooling solution can meet the cooling requirements, but if the ambient temperature is high, the refrigerator 3 needs to be used for high-efficiency cooling.

[0058] In the traditional solution, once the natural cooling cannot meet the requirements, the refrigerator 3 will be fully used for cooling. However, the ambient temperature is not constant. It is very large. It is very likely that the temperature in the morning and evening is only a few degrees, but the temperature at noon can reach 20 to 30 degrees. If the cooling source (natural cooling source, refrigerator 3) is switched across the board, it will inevitably lead to natural cooling. The utilization o...

Embodiment 2

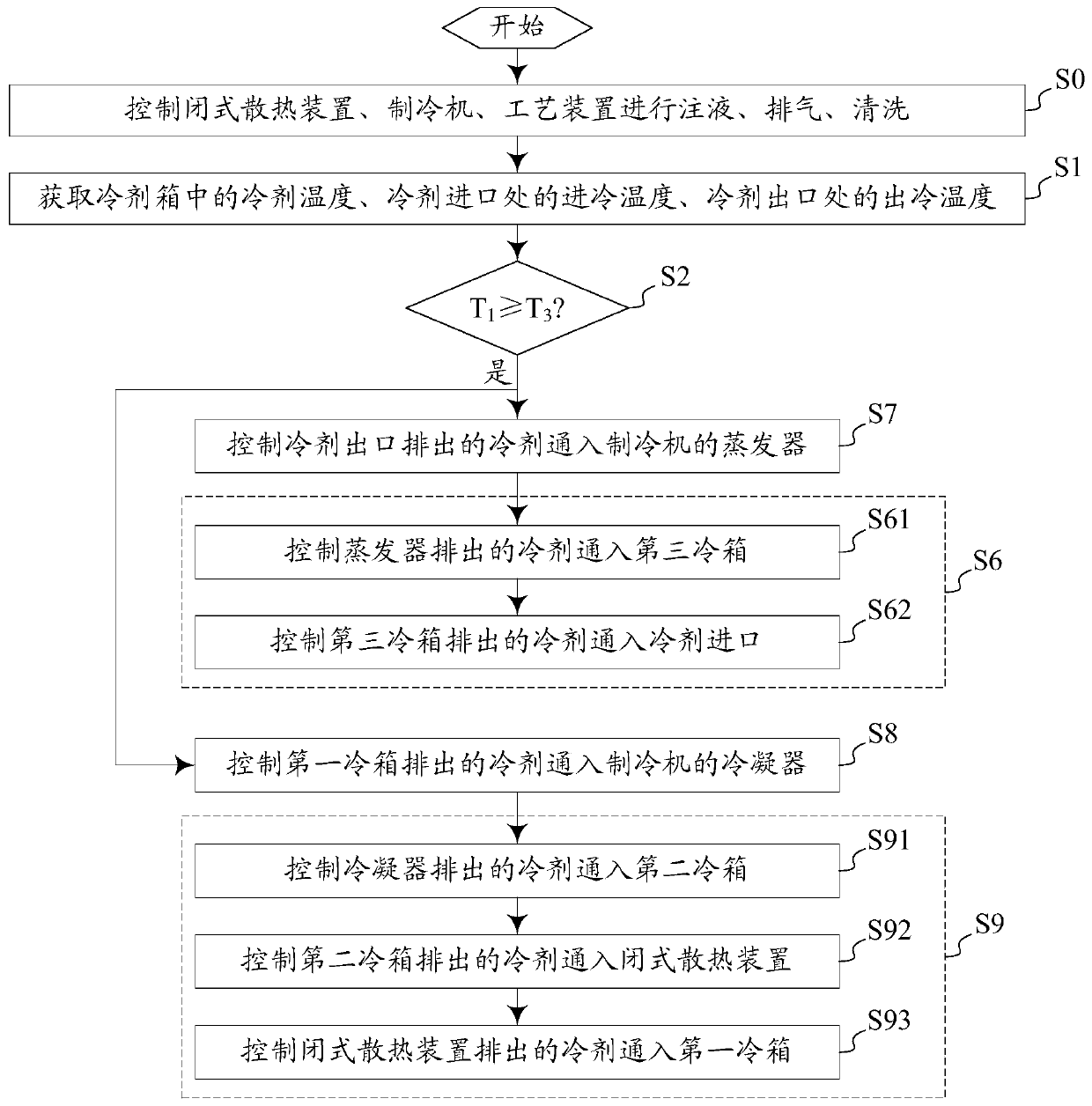

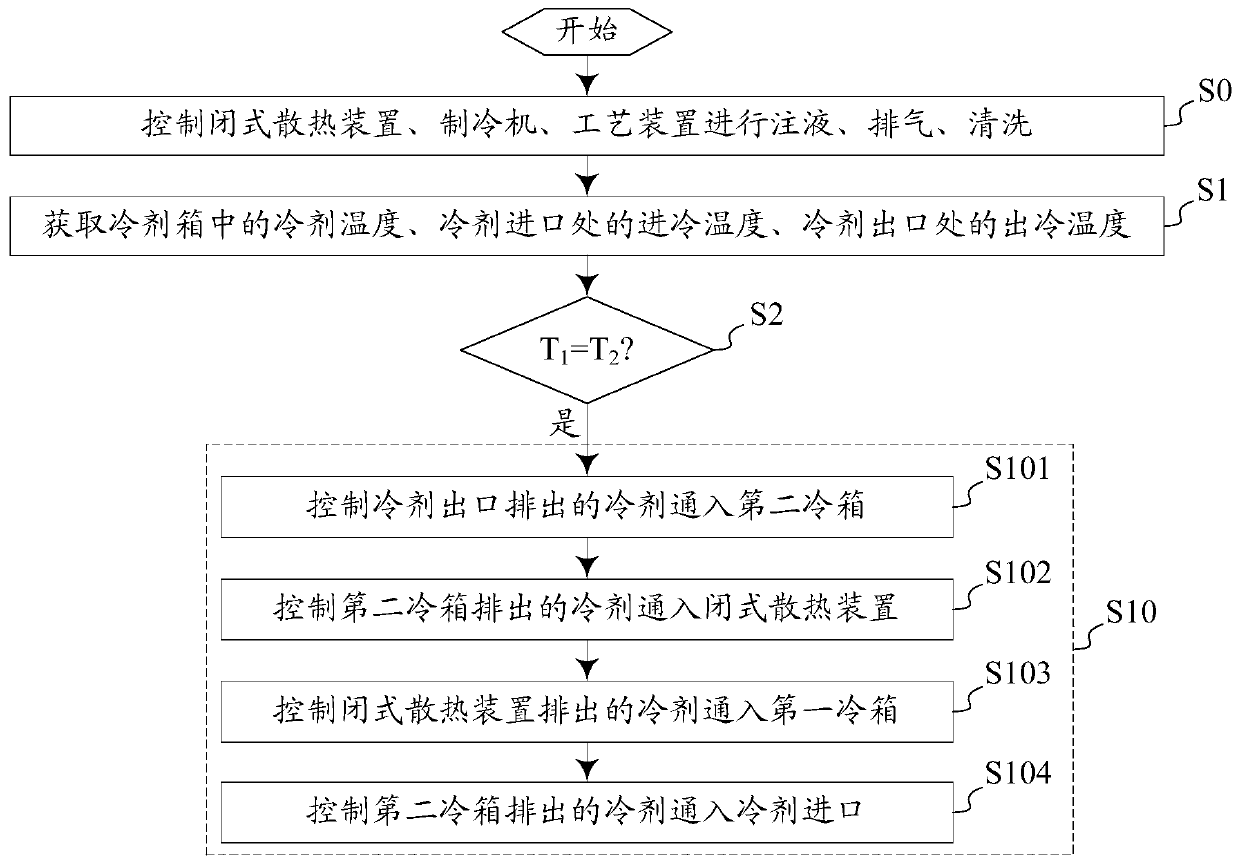

[0086] This embodiment also provides a cooling cycle system, including a refrigerant tank 1, a closed cooling device 2 and a refrigerator 3, and the cooling cycle system communicates with the refrigerant inlet 41 and the refrigerant outlet 42 of the process device 4; it also includes a second A temperature sensor, a second temperature sensor and a third temperature sensor, the first temperature sensor is used to monitor the refrigerant temperature T of the refrigerant tank 1 1, the second temperature sensor is located at the refrigerant inlet 41 for monitoring the inlet cooling temperature T in the refrigerant outlet 42 2 , the third temperature sensor is located at the refrigerant outlet 42 for monitoring the cooling temperature T in the refrigerant outlet 42 3 ; Also includes a controller (not shown in the figure), the controller is connected with the first temperature sensor, the second temperature sensor signal, the controller is suitable for cooling temperature T 2 1 3 U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com