A kind of preparation method and application of low molecular weight dextran iron

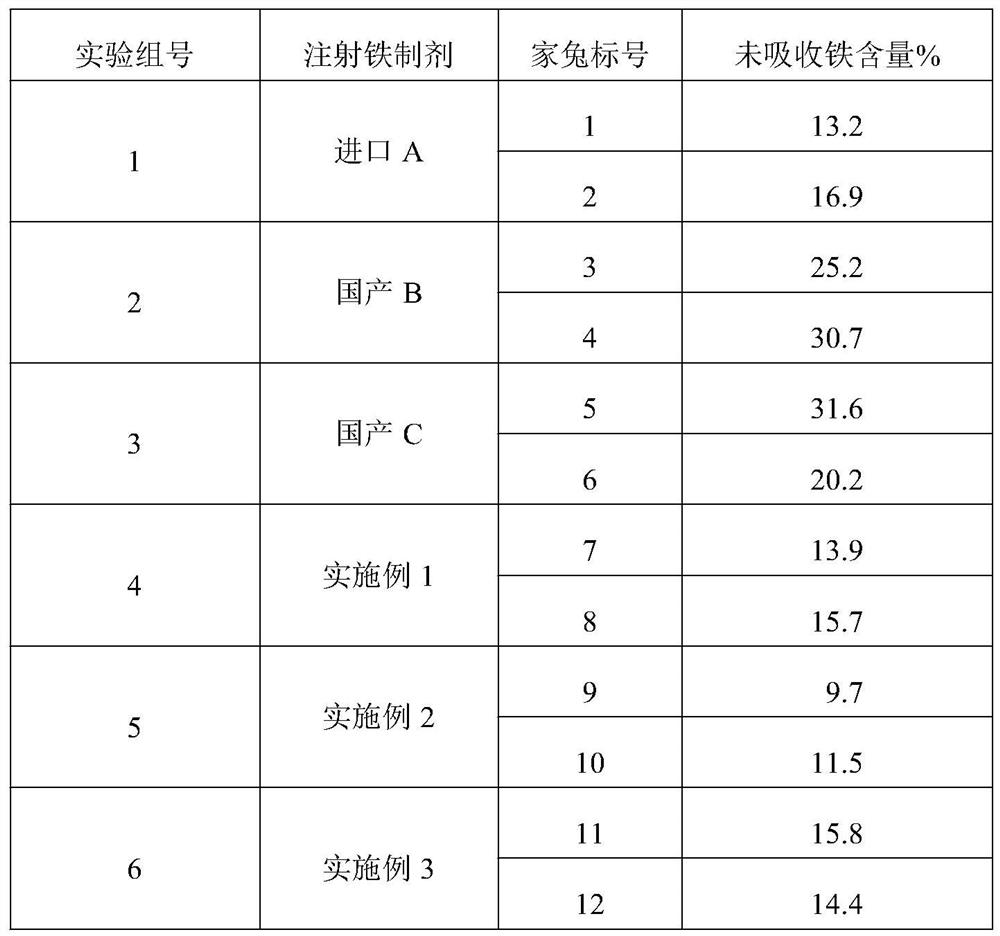

A technology of iron dextran and low molecular weight, which is applied in the field of preparation of iron low molecular weight dextran, which can solve the problems of varying lengths of low molecular weight dextran chains, increasing the pressure of "three wastes" treatment, and the high pressure of "three wastes" treatment, etc. problem, to achieve the effect of improving complexation effect, narrow molecular weight distribution range, and significant iron supplementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of low-molecular-weight dextran solution: Weigh 200g of sucrose, weigh 100g of maltose, add water to dissolve and dilute to 1000mL, put them into a 2L three-necked bottle; add 0.1g of calcium chloride, and adjust the pH with 10% acetic acid To 5.2-5.5, add dextran sucrase 10000U; stir and react at 15-30°C for 24h; heat the reaction solution to 80-90°C and keep stirring for 1-2 hours to inactivate the enzyme; filter to remove protein impurities and other insoluble impurities to obtain a low-molecular-weight dextran solution.

[0036](2) Preparation of low-molecular-weight dextran iron solution: Add 45 g of sodium citrate to the low-molecular-weight dextran solution obtained in step (1), heat up to 80° C. and stir for 2 hours, then add dropwise 20% sodium hydroxide solution 200mL, after the dropwise addition, keep stirring at 80-85°C for 7 hours; cool the reaction system to 55°C, adjust the pH to 5.0-5.5 with hydrochloric acid solution, then add 200mL of 2...

Embodiment 2

[0040] (1) Preparation of low-molecular-weight dextran solution: Weigh 250g of sucrose, weigh 50g of maltose, add water to dissolve and dilute to 1000mL, and put them into a 2L three-necked bottle; add 0.2g of calcium chloride, and adjust the pH with 10% acetic acid To 5.2-5.5, add dextran sucrase 11000U; stir the reaction at 15-30°C for 30h; heat the reaction solution to 80-90°C and keep stirring for 1-2 hours to inactivate the enzyme and terminate the reaction; filter to remove Protein impurities and other insoluble impurities were obtained, and the low-molecular-weight dextran solution was directly used in the next step of preparation without purification and solidification.

[0041] (2) Preparation of low-molecular-weight dextran iron solution: Add 40 g of sodium citrate to the low-molecular-weight dextran solution obtained in step (1), heat up to 80° C. and stir for 2 hours, then add dropwise 20% sodium hydroxide solution 200mL, after the dropwise addition, keep stirring ...

Embodiment 3

[0045] (1) Preparation of low-molecular-weight dextran solution: Weigh 270g of sucrose and 27g of maltose, add water to dissolve and dilute to 1000mL, put them into a 2L three-necked bottle; add 0.4g of calcium chloride, and adjust the pH with 10% acetic acid To 5.2-5.5, add dextran sucrase 13000U; stir the reaction at 15-30°C for 36h; heat the reaction solution to 80-90°C and keep stirring for 1-2 hours to inactivate the enzyme and terminate the reaction; filter to remove Protein impurities and other insoluble impurities were obtained, and the low-molecular-weight dextran solution was directly used in the next step of preparation without purification and solidification.

[0046] (2) Preparation of low-molecular-weight dextran iron solution: Add 45 g of sodium citrate to the low-molecular-weight dextran solution obtained in step (1), heat up to 80° C. and stir for 2 hours, then add dropwise 20% sodium hydroxide solution 200mL, after the dropwise addition, keep stirring at 80-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com