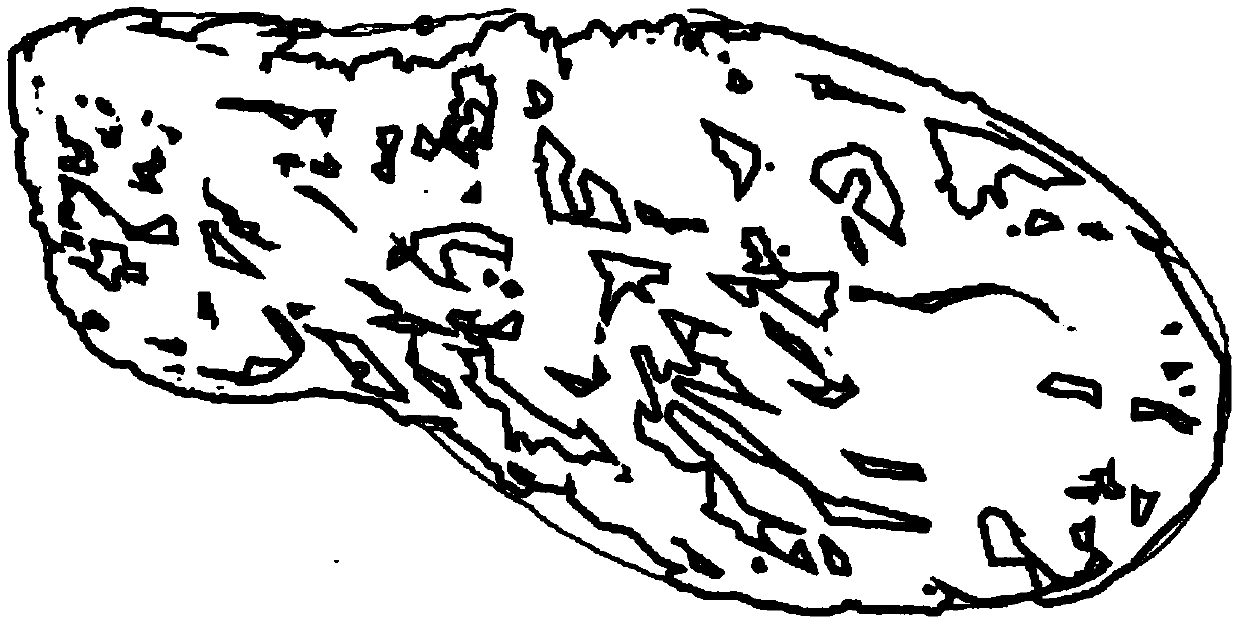

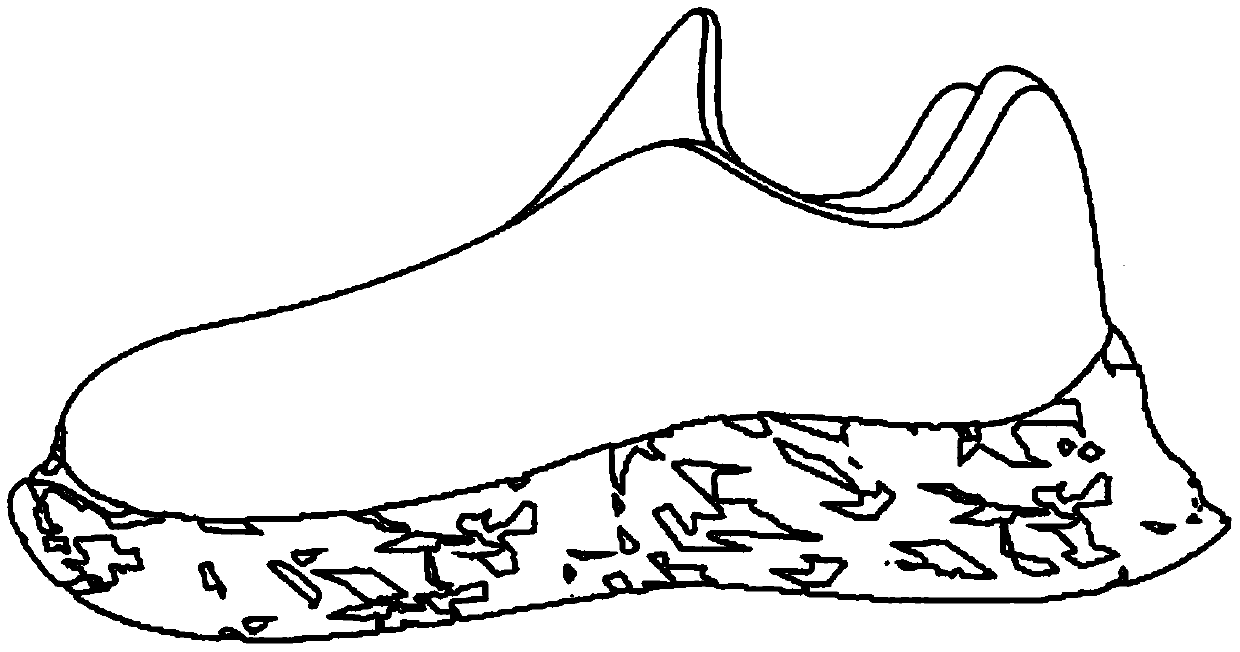

Preparation method for castable camouflage mixed-color foamed polyurethane shoe sole

A technology for foaming polyurethane and a manufacturing method, which is applied in the directions of soles, applications, footwear, etc., can solve problems such as inability to meet the taste of appreciation, and achieve the effects of good wear resistance and anti-slip function, easy processing, and novel and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. Those skilled in the art should understand that the examples are only used to help understand the present invention, and should not be regarded as specific limitations on the present invention.

[0018] A method for manufacturing castable camouflage mixed-color foamed polyurethane soles, the polyurethane resin comprises three components:

[0019] Component A: polyester or polyether polyol mixture;

[0020] B component: isocyanate prepolymer;

[0021] C component: catalyst;

[0022] Described manufacturing method comprises the steps:

[0023] First, according to a certain proportion, add C component and other auxiliary agents to A component, after fully mixing evenly, it can be added to the A material tank of the shoe sole molding machine, and B component can be directly added to the corresponding B material tank after heating and melting In the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com