Thermal-insulation safety cover for glass fiber reinforced plastic composite

A technology of glass fiber reinforced plastics and protective covers, which is applied in the direction of heat preservation, pipeline protection, and pipeline protection through heat insulation, etc. It can solve the problems of inconvenient disassembly and installation, difficult to reach, easy to corrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

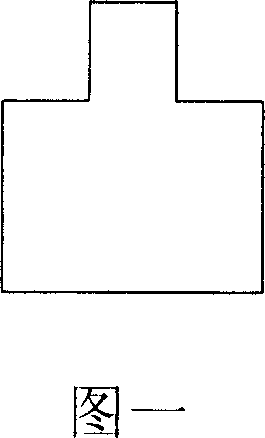

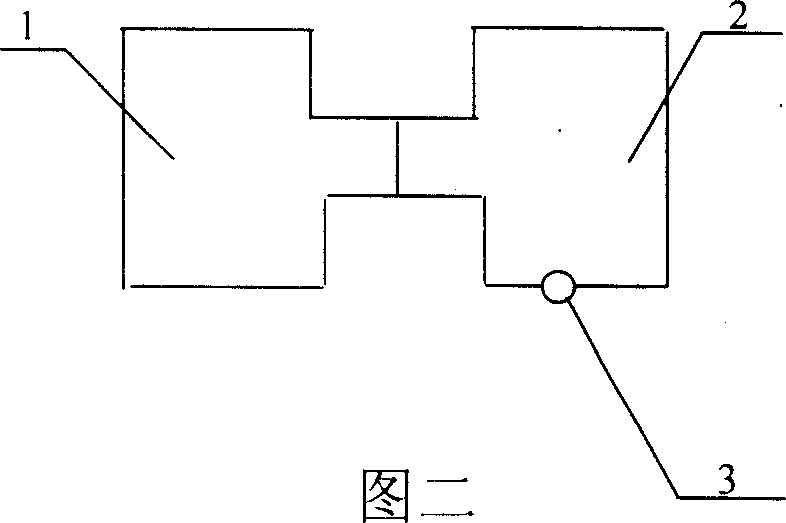

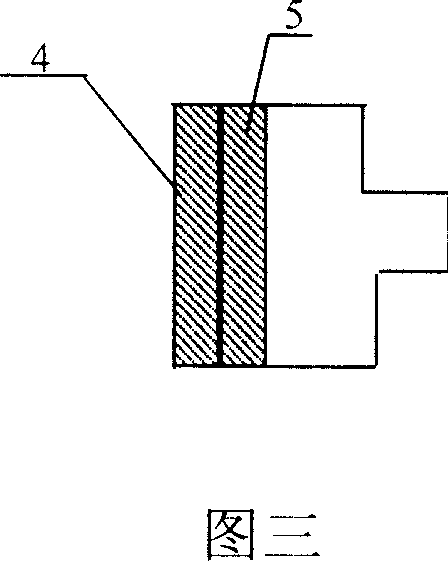

[0012] A glass fiber reinforced plastic valve insulation protection cover is composed of two parts, a left cover body 1 and a right cover body 2 . The left cover body 1 and the right cover body 2 are made of fiberglass material, and flame-retardant material 5 is arranged inside it. Among them, the left cover body 1 and the right cover body 2 are equipped with aluminum silicate thermal insulation cotton 4, and there are installation holes 3 around the left cover body 1 and the right cover body 2, and the left cover body is installed on the left side of the valve by stainless steel screws, and the right The cover body is installed on the right side of the valve.

[0013] In addition to the above advantages, the present invention also has the advantages of high smoothness, no fading, no deformation, convenient disassembly and easy installation. During the maintenance process of the power plant, it saves time, improves work efficiency, and overcomes the disadvantage that thermal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com