Combined-type submerged breakwater structure and manufacturing method thereof

A combined and submerged embankment technology, applied in the field of port and coastal engineering, can solve the problems of material waste, project cost, unstable submerged embankment structure, ecological environment damage, etc., and achieve low cost, ecological maintenance, and ecological significance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

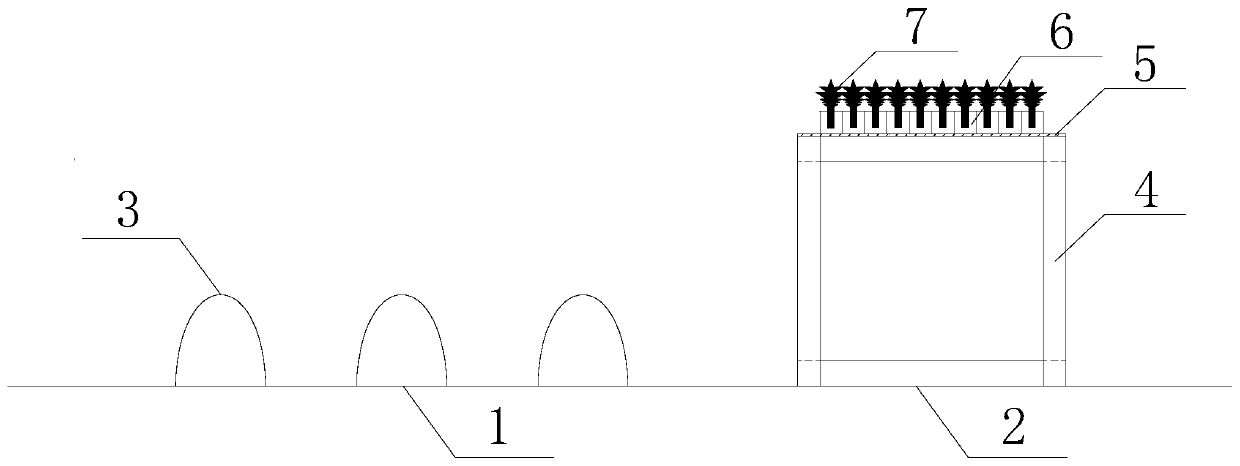

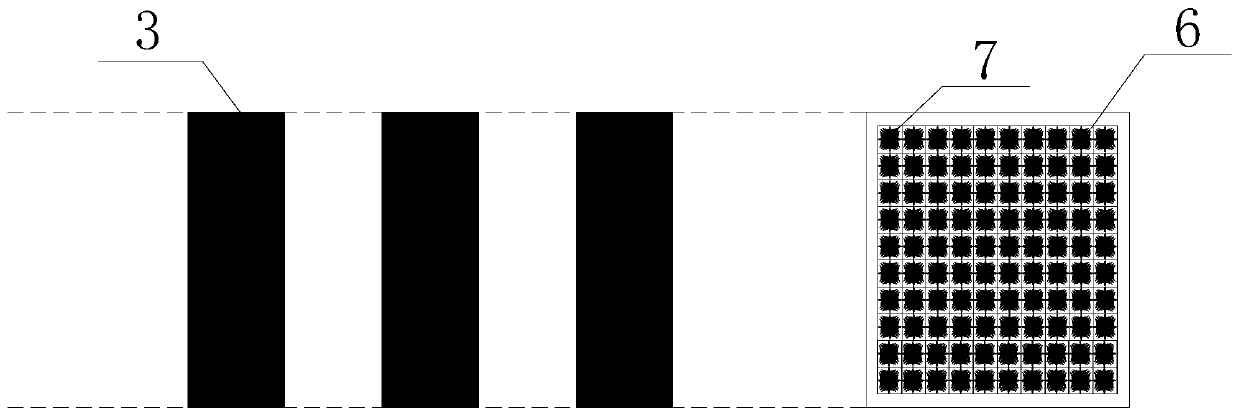

[0034] Embodiment 1, the manufacturing method of combined submerged embankment structure

[0035] Step 1: Collect the wave height of the waves in the target sea area H ,wavelength L ,cycle T and water depth h The data.

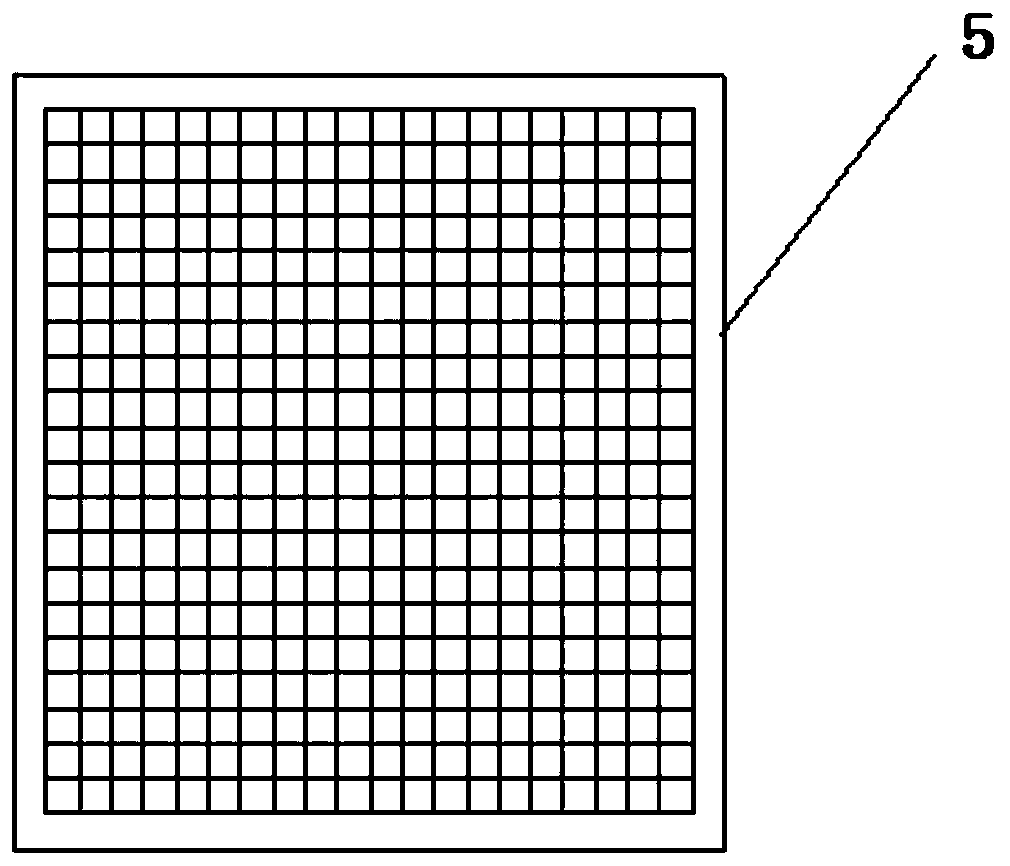

[0036] Step 2: Determine the size of the peak cylinder unit and the length of the peak cylinder unit based on the data in step 1 l Determined according to the length of the protective coast, the wavelength of the crest cylinder unit L b is the incident wavelength of waves in the target sea area L half of the amplitude of the crest cylinder element D and water depth h The ratio is 0.16;

[0037] Step 3. In the target sea area, arrange the three prefabricated crest cylinders in step 2 in a periodic manner, and the distance between adjacently arranged wave crest cylinder units d with the wavelength of the crest cylinder unit L b Equal, the undulating extension direction of its periodic arrangement is consistent with the incident wave direction of the ...

Embodiment 2

[0041] Embodiment two, the manufacturing method of combined submerged embankment structure

[0042] Step 1: Collect the wave height of the waves in the target sea area H ,wavelength L ,cycle T and water depth h The data.

[0043] Step 2: Determine the size of the peak cylinder unit and the length of the peak cylinder unit based on the data in step 1 l Determined according to the length of the protective coast, the wavelength of the crest cylinder unit L b Equal to the incident wavelength of the waves in the target sea area L , the amplitude of the crest cylinder element D and water depth h The ratio is 0.18;

[0044] Step 3. In the target sea area, arrange the 4 crest cylinders prefabricated in step 2 in a periodic manner, and the distance between adjacently arranged wave crest cylinder units d with the wavelength of the crest cylinder unit L b Equal, the undulating extension direction of its periodic arrangement is consistent with the incident wave direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com