Anti-floating underground garage only with supporting piles and construction method of anti-floating underground garage

A technology for underground garages and supporting piles, which is applied in the direction of protection devices, infrastructure engineering, buildings where cars are parked, etc. It can solve the problems of increasing the drainage pressure of underground garages and the inability to remove the influence of groundwater on the buoyancy of garages, so as to improve the anti-floating The effects of safety, enhanced practicality, and extended overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

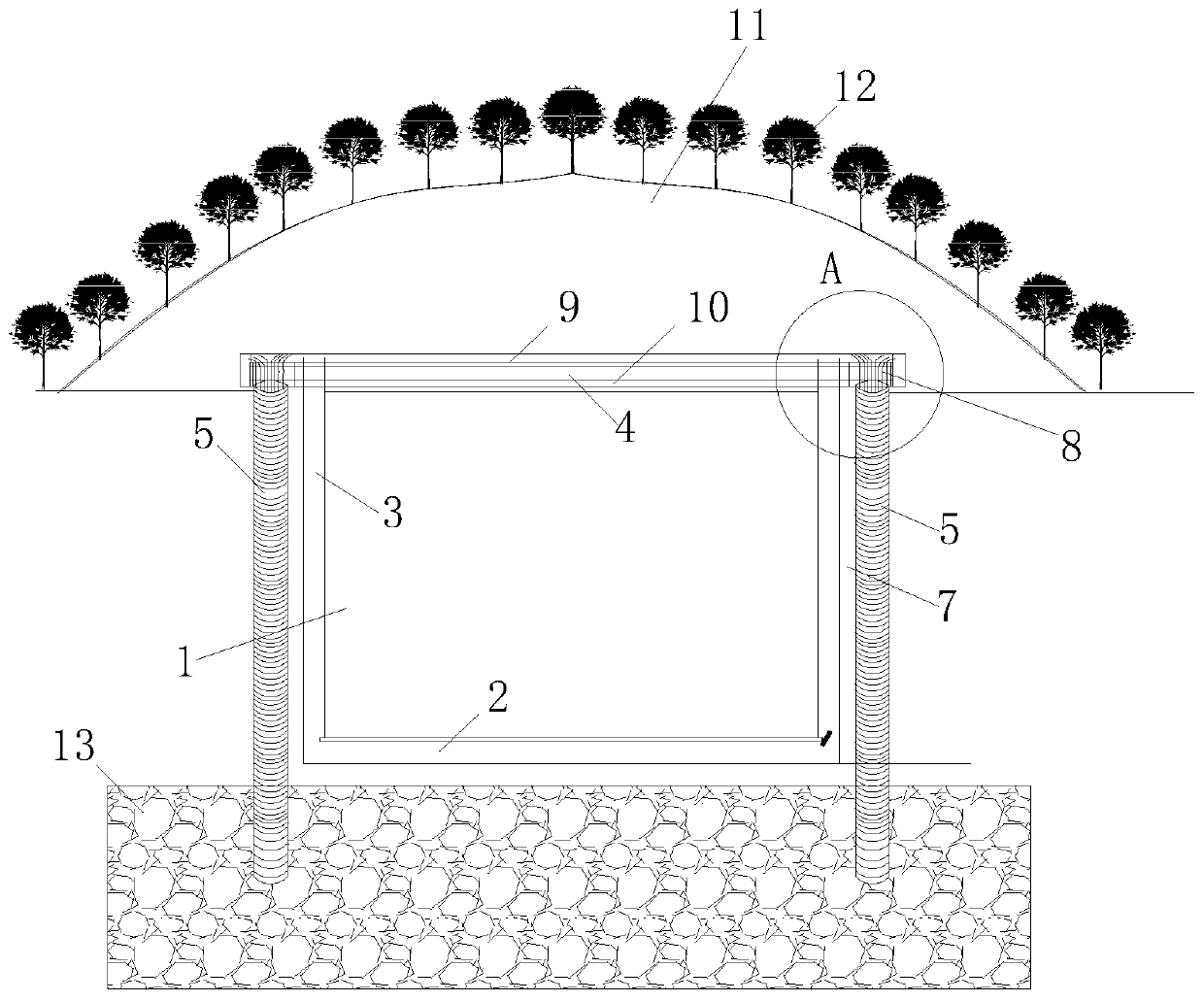

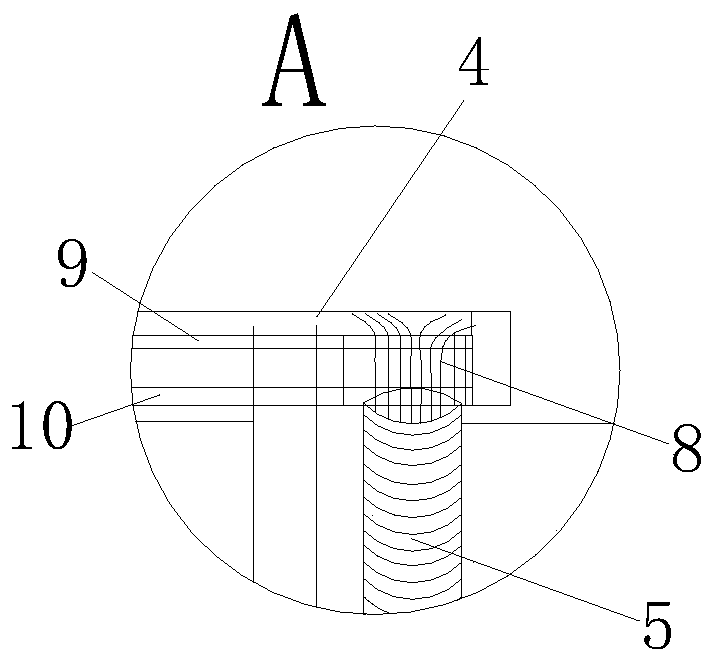

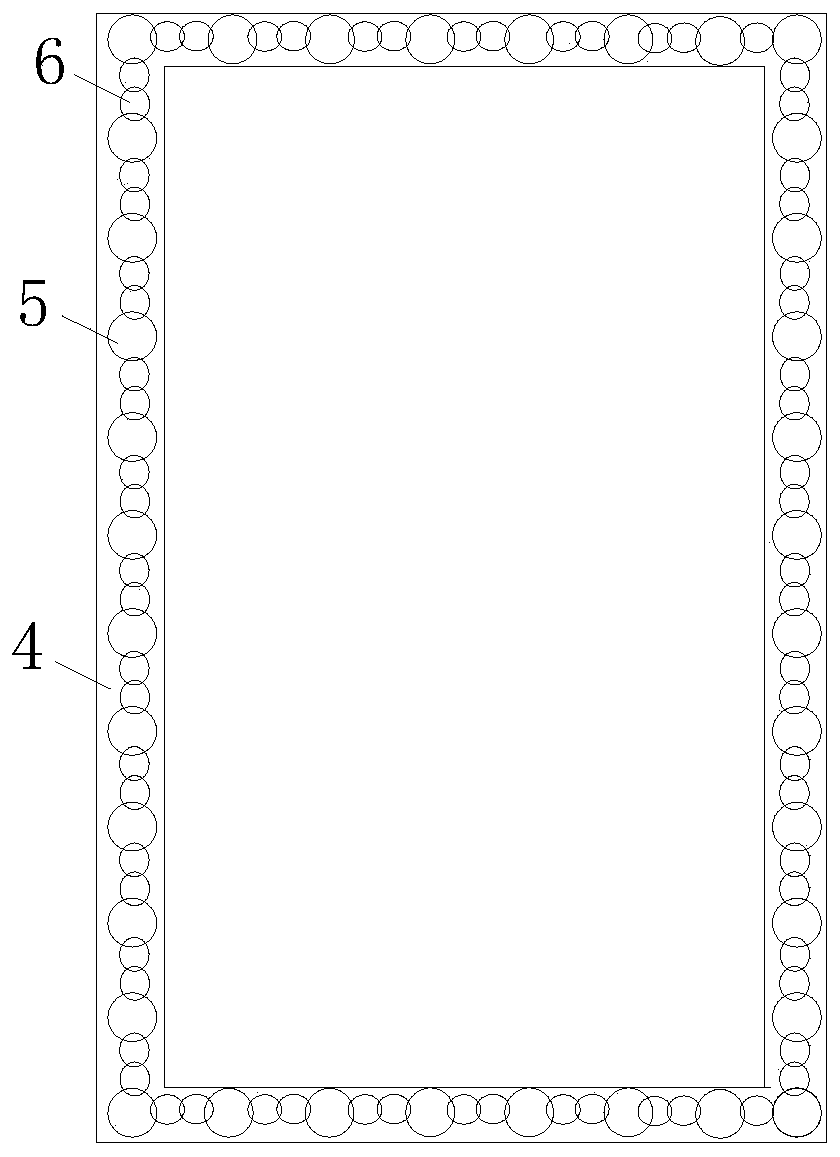

[0032] From Figure 1-3 It can be seen that a kind of anti-floating underground garage with only supporting piles in this embodiment includes an underground garage main body 1, and the underground garage main body 1 is composed of a garage floor 2, a garage wall panel 3, and a garage roof 4. The garage floor 2, The garage wall board 3 and the garage top board 4 jointly form the main body 1 of the underground garage. The garage wall board 3 is arranged on the edge of the garage bottom board 2. The upper end of the garage wall board 3 is connected with the garage roof board 4. The side of the underground garage main body 1 is provided with Bored cast-in-place piles 5, the bottom of bored cast-in-place piles 5 is provided with strengthened wind rock layer 13, between adjacent bored cast-in-place piles 5 is provided with cement rotary grouting piles 6, the bored cast-in-place piles 5 and cement rotary grouted piles 6 The lower ends jointly resist the groundwater, the bottoms of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com