Shale oil reservoir multistage crack diversion capacity optimization method

A technology of diversion capacity and optimization method, which is applied in the fields of mining fluid, earthwork drilling, data processing application, etc., can solve problems such as low permeability and porosity, and unclear understanding of diversion capacity, so as to improve the transformation effect and achieve high efficiency The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Example A Method for Optimizing the Conductivity of Multi-stage Fractures in Shale Reservoirs

[0030] Include the following steps:

[0031] S1. Optimization of the complex fracture reconstruction body to obtain the characteristics of the shale reservoir (the porosity of the shale oil well is 2.4%, the reservoir permeability is 0.073mD, and the reservoir thickness is 35m). According to the theory of oil and gas seepage mechanics, the complex fracture The modified body is equivalent to a high-permeability body, the post-fracture production under different parameters is simulated, and the volume of the modified body is optimized according to the production volume of 7×10 4 m 3 and permeability 6mD;

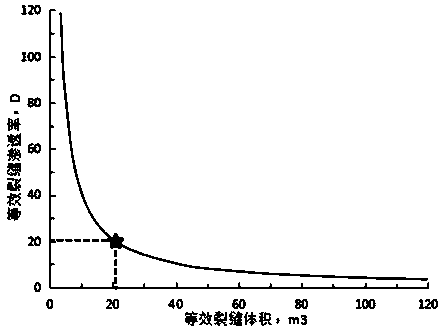

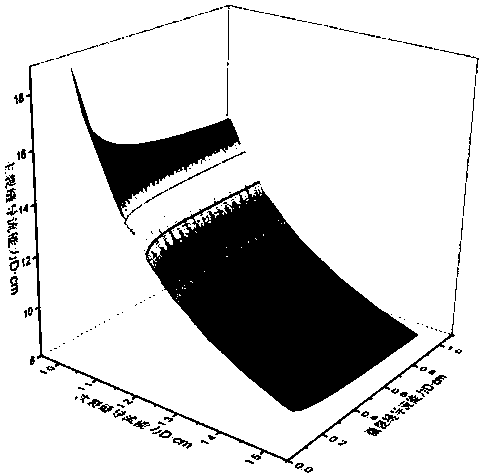

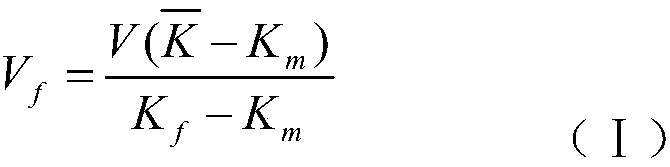

[0032] S2. Obtain the permeability of the shale reservoir, combine the volume and permeability of the reformed body obtained in step S1, and use the formula (I) to obtain the relationship curve between the equivalent fracture volume and the equivalent fracture permeability,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com