Double-stage air supplementing horizontal rolling rotor compressor

A rolling rotor type and compressor technology, which is applied to rotary piston type/oscillating piston type pump components, machines/engines, liquid fuel engines, etc., and can solve problems such as low lubricating oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

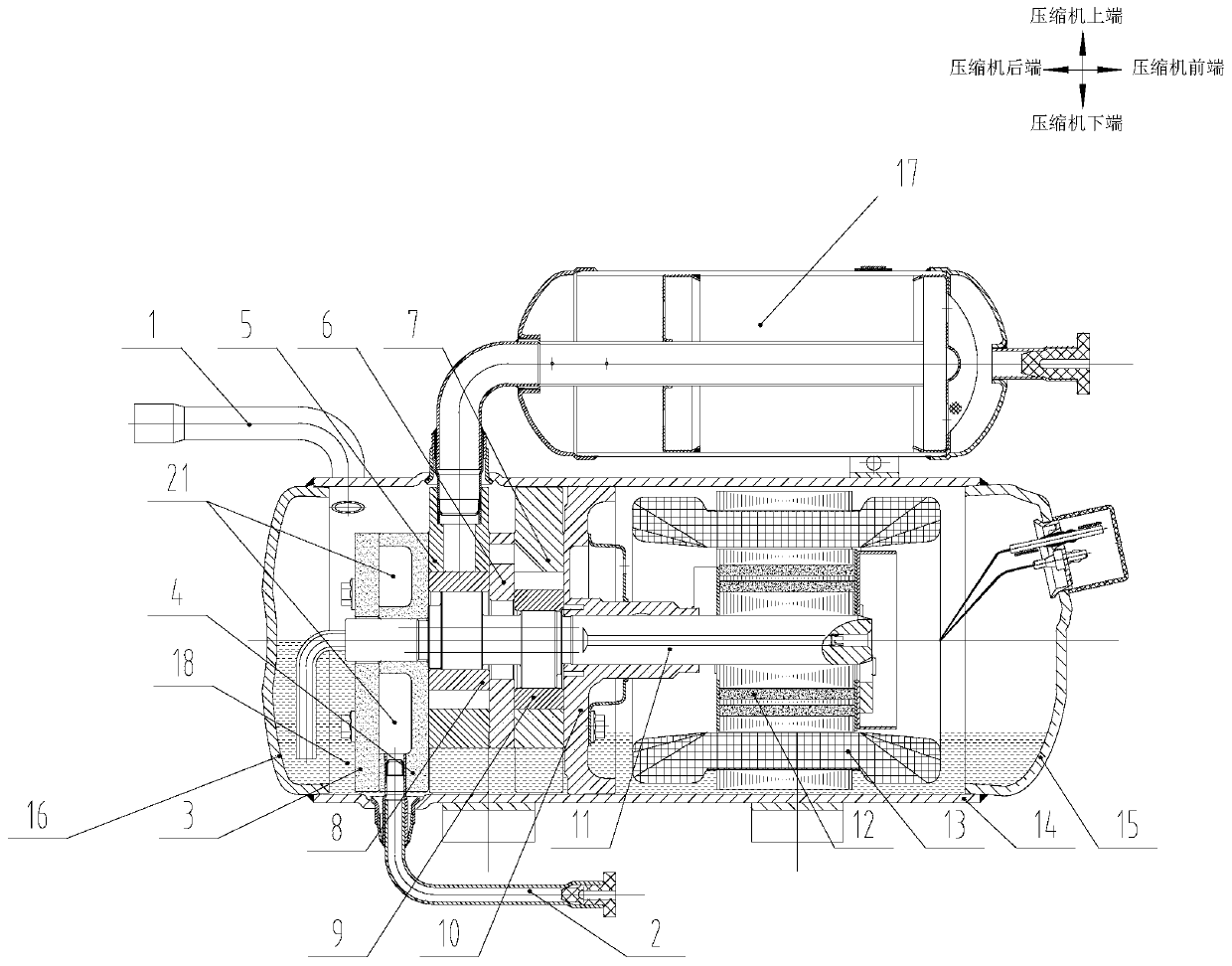

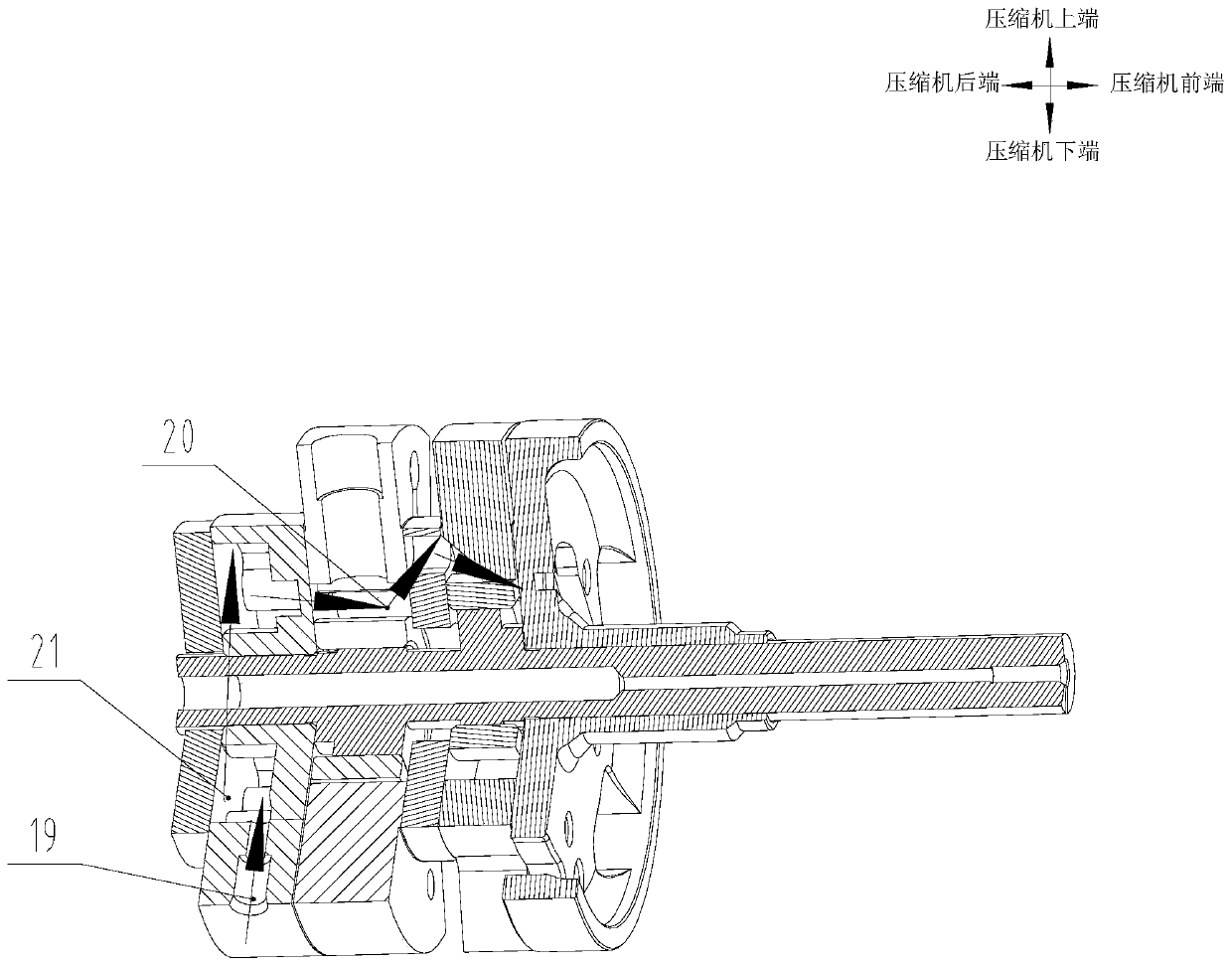

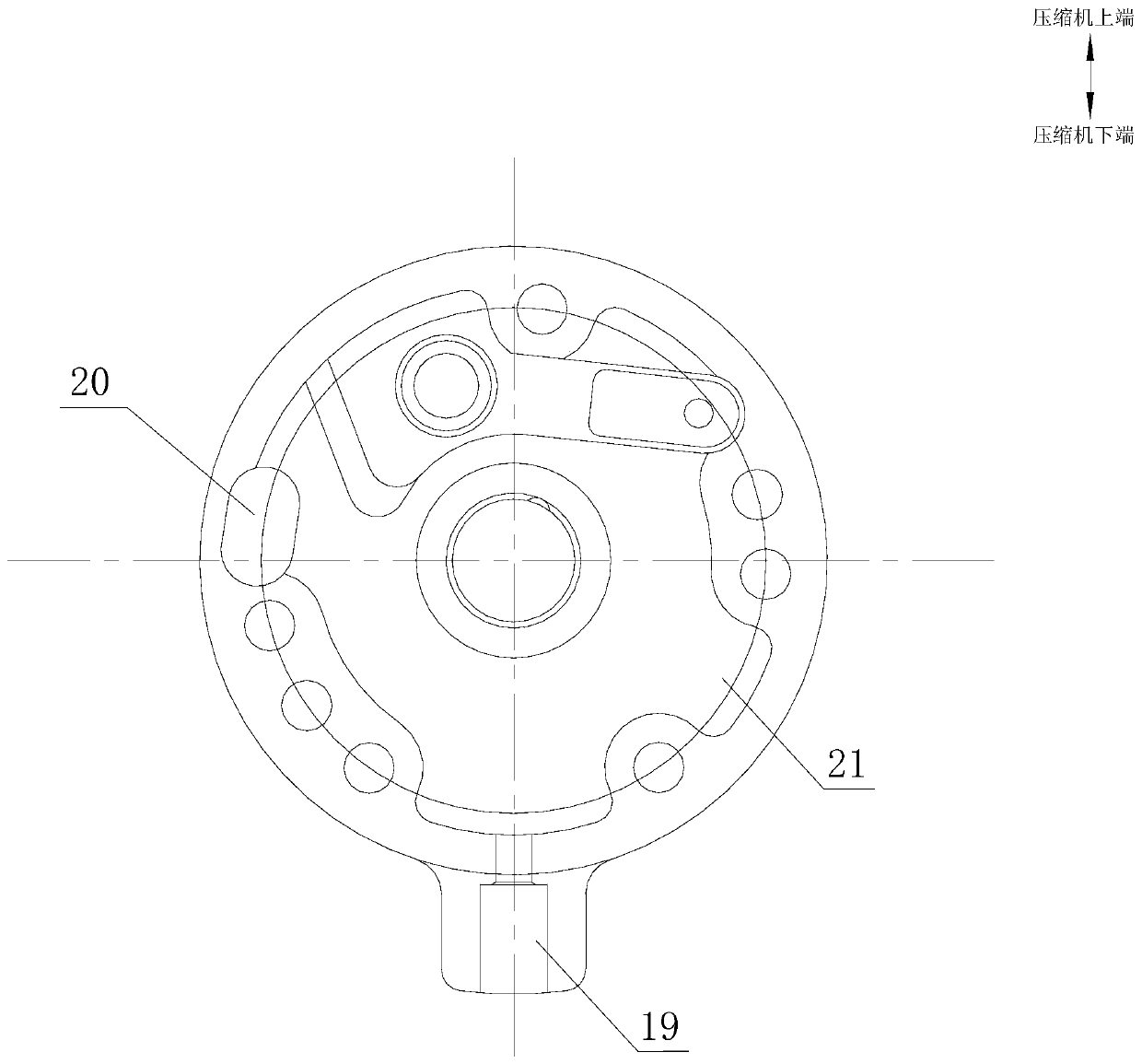

[0054] A two-stage gas-supplying horizontal scrolling rotor compressor, such as Figure 5 As shown, a housing 14 is included, and the front and rear ends of the housing 14 are respectively closed by a front cover assembly 15 and a rear cover 16 . The inside of the casing 14 is a cavity for accommodating relevant components of the compressor, the top of the casing 14 is connected to the liquid distributor, and the bottom of the casing 14 is filled with refrigerating oil to form an oil pool 18 . The liquid level of the oil pool 18 has a certain height, as if parts inside the compressor are partly immersed in the refrigerating oil, and the refrigerating oil has the effect of lubricating and cooling.

[0055] Wherein, the casing 14 is provided with an exhaust pipe 1 for discharging the air compressed by the compressor.

[0056] A motor stator 13 and a motor rotor assembly 12 are provided inside the compressor near the front cover assembly 15 . One end of the crankshaft 11 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com