Movable flap plate assembly, fume collection cavity with movable flap plate assembly, and exhaust hood

A technology of range hoods and flip panels, which is applied in applications, removal of oil fumes, household stoves, etc. It can solve the problem that the negative pressure area of the air inlet is far from the area where the oil fume occurs, the size of the smoke collection chamber cannot be adjusted arbitrarily, and the effect of absorbing oil fume is not good. problems, to achieve the effect of easy absorption, easy oil fume, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

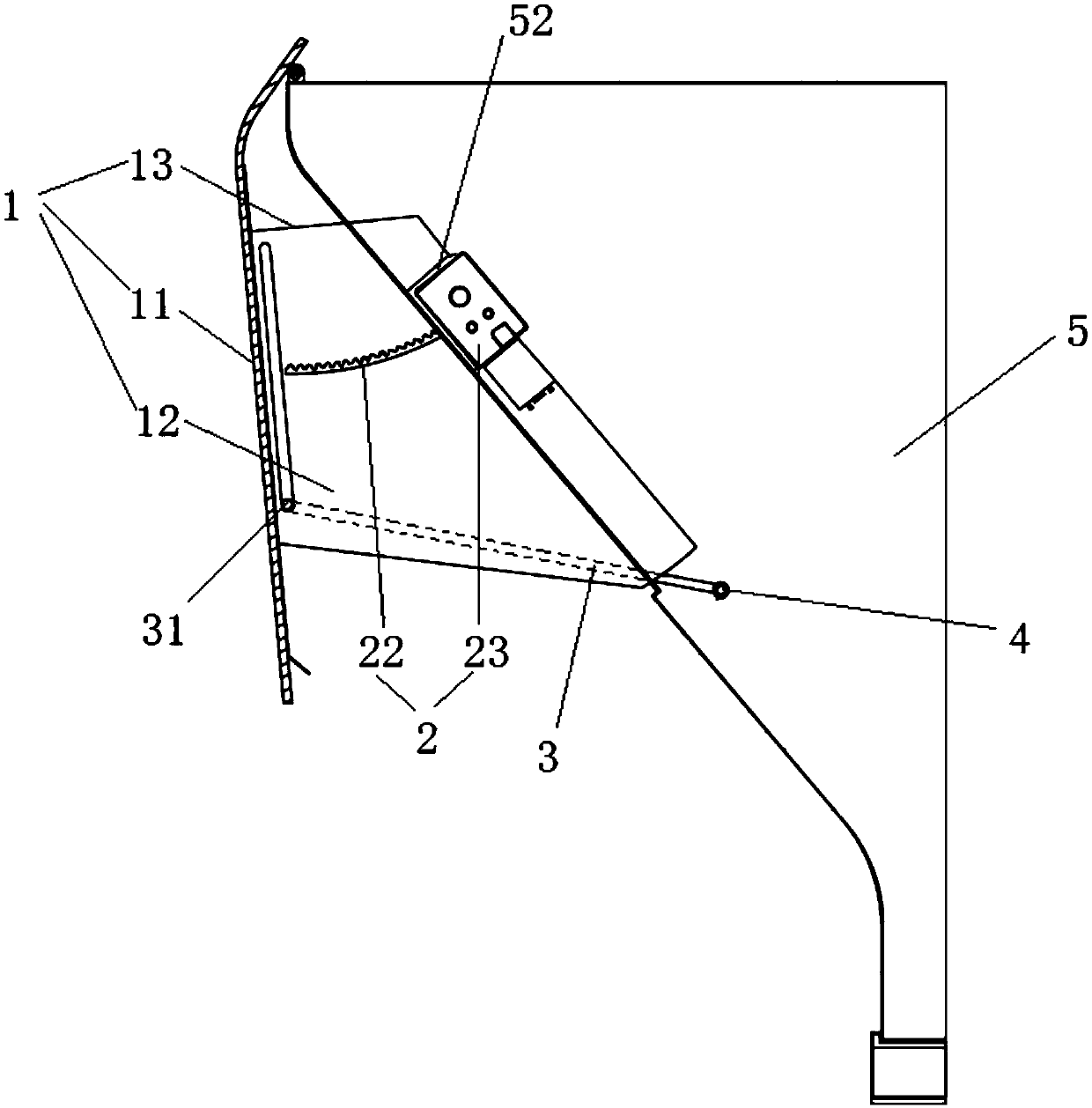

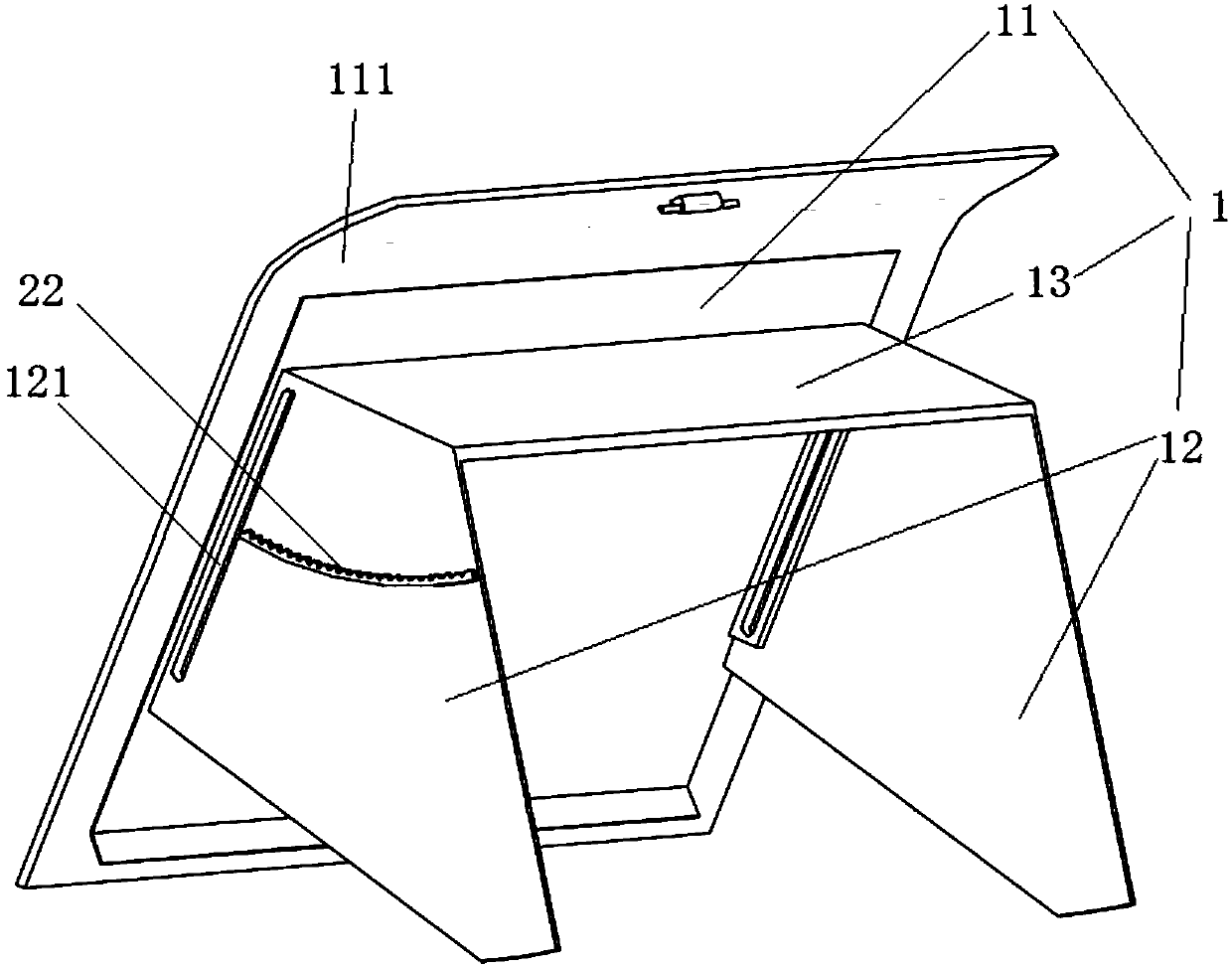

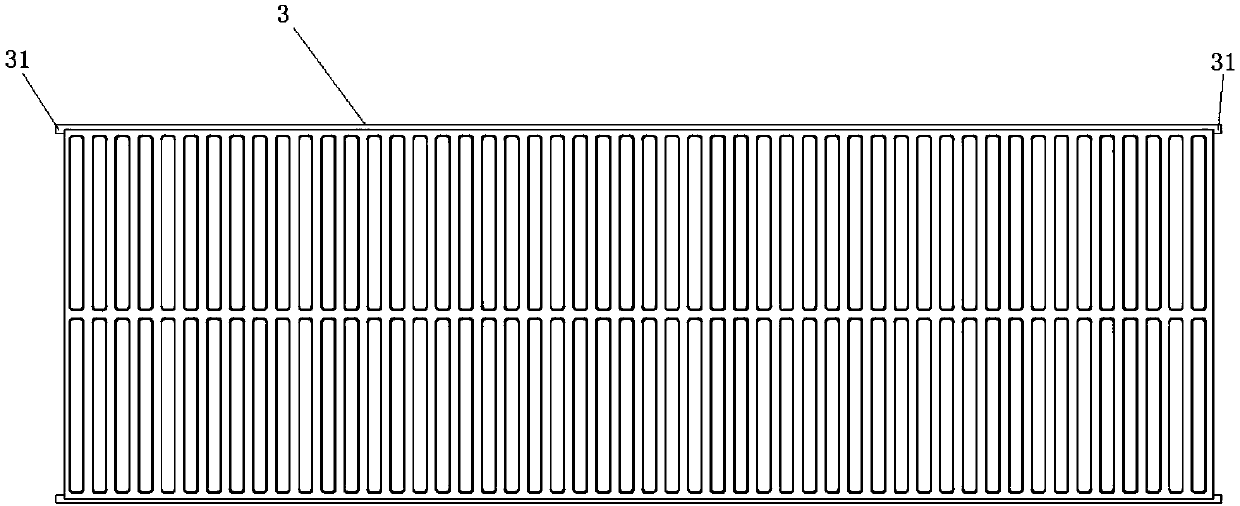

[0027] An embodiment of the present invention provides a movable flip panel assembly, which is arranged on the smoke collection hood of the range hood, such as figure 1 As shown, it includes a flip panel 1, a drive unit 2, the drive unit 2 is connected to the flip panel 1, and the drive unit 2 drives the flip panel 1 to open or close; by setting the movable flip panel 1 in front of the smoke collecting hood 5, avoiding The problem of not being able to adjust the size of the smoke collecting chamber arbitrarily has realized not only having a larger smoke collecting chamber compared to side suction r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com