Liquid membrane lens combined zoom optical system

A technology of lens combination and optical system, which is applied in the field of zoom optical system to achieve the effect of reducing cost, reducing manufacturing cost and reducing lens volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

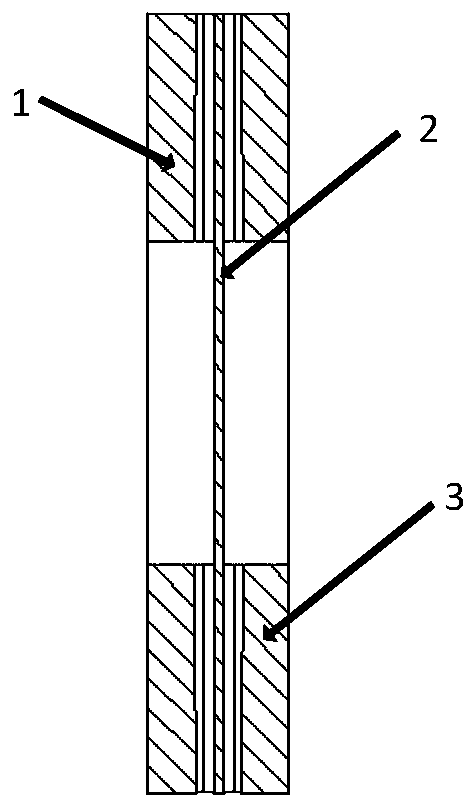

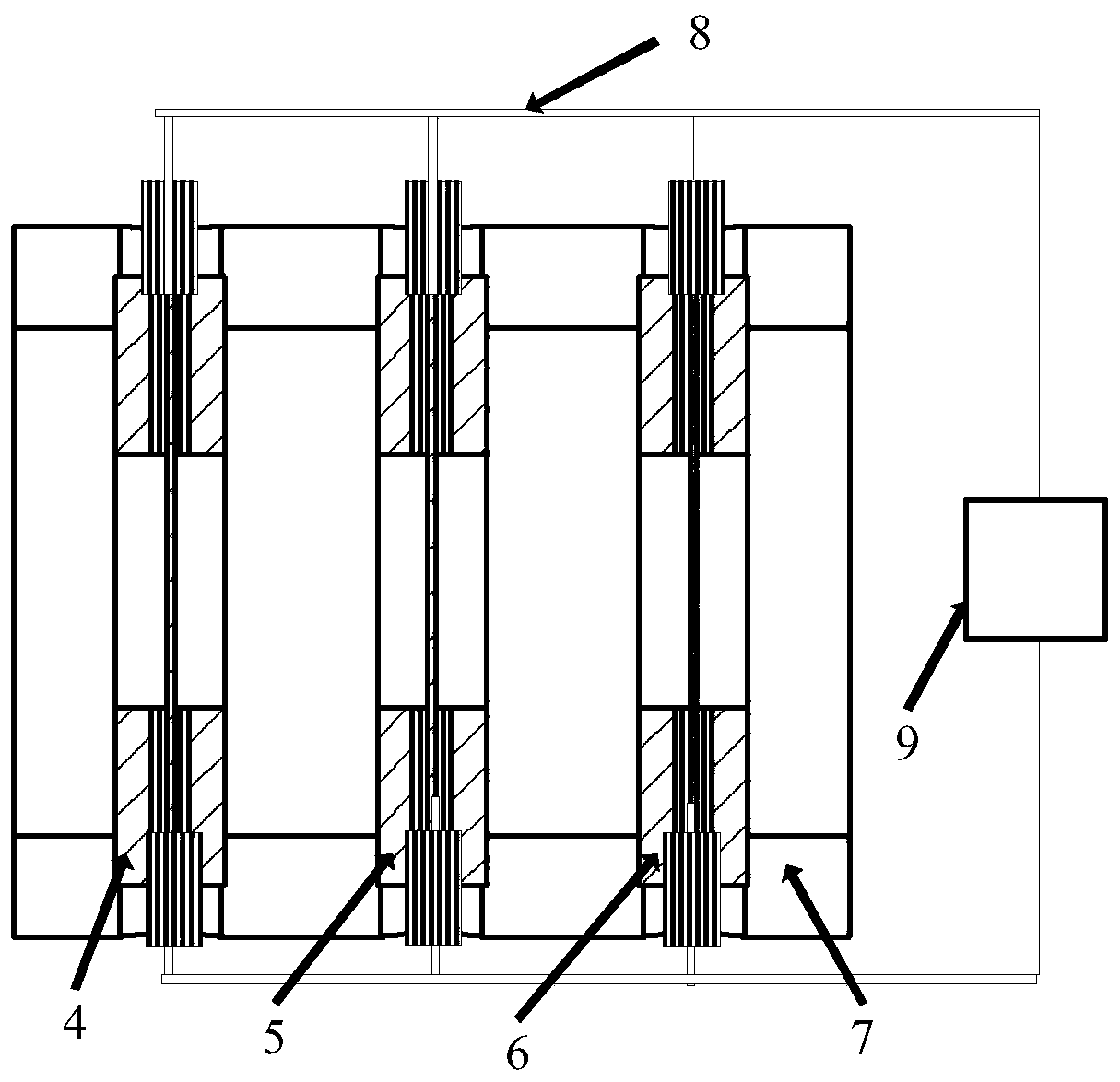

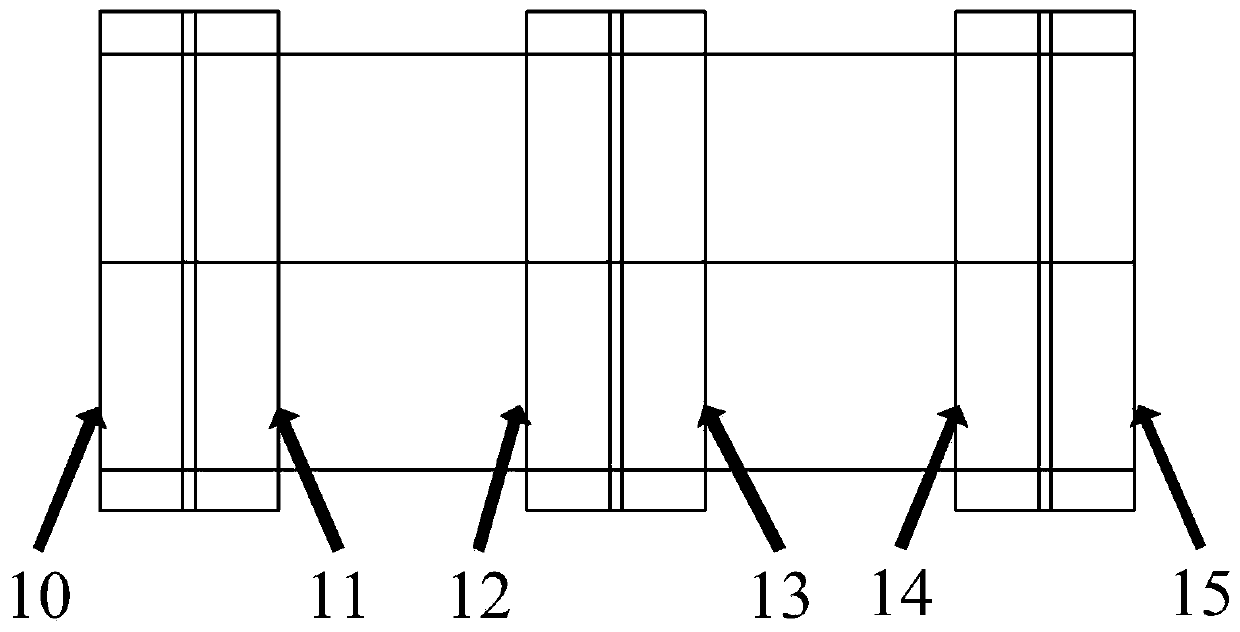

[0046] like figure 1 As shown, the liquid film lens disclosed in this embodiment is mainly composed of a front lens cavity 1 , a flat glass 2 and a rear lens cavity 3 . The inner diameter of the cavity of the liquid film lens is D=6mm, the thickness of the cavity is h=1mm, the liquid material is water, the material of the flat glass 2 is K9 glass, and the thickness of the flat glass is 0.15mm. The liquid is injected or extracted into the front lens cavity through the liquid channel, and the liquid surface in front of the lens is deformed by controlling the volume of the liquid in the front lens cavity and utilizing the surface tension of the liquid itself. The liquid is injected or extracted into the rear lens cavity through the liquid channel, and the liquid surface deformation behind the lens is realized by controlling the volume of the liquid in the rear lens cavity and utilizing the surface tension of the liquid itself. By controlling the deformation of the liquid surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com