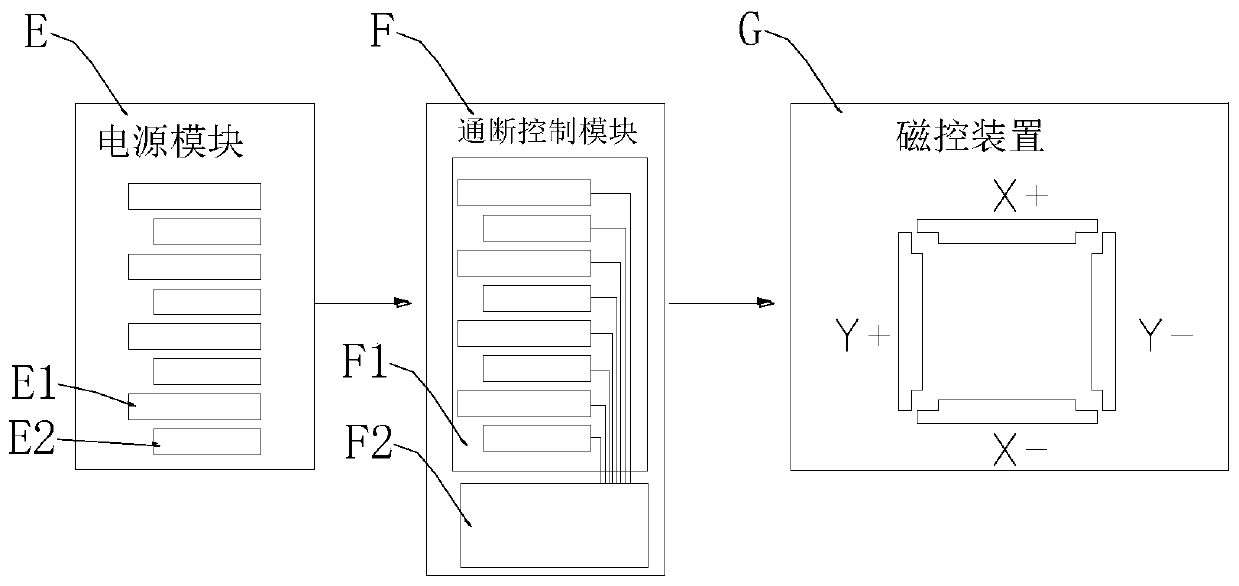

Multi-channel power supply circuit based on magnetic particle magnetic control aggregation device

A technology of power supply circuit and magnetic particles, which is applied in the direction of circuits, output power conversion devices, magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

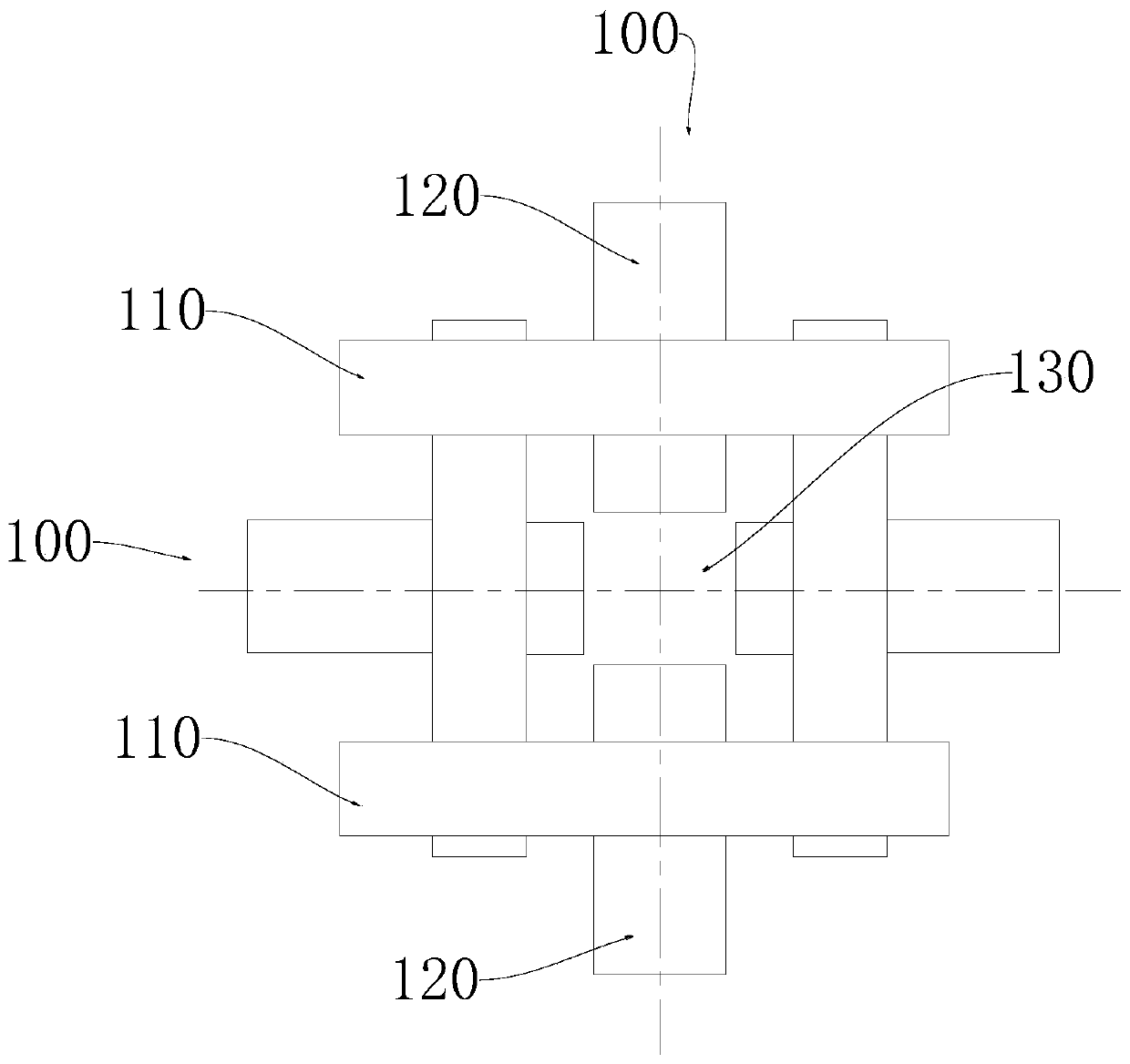

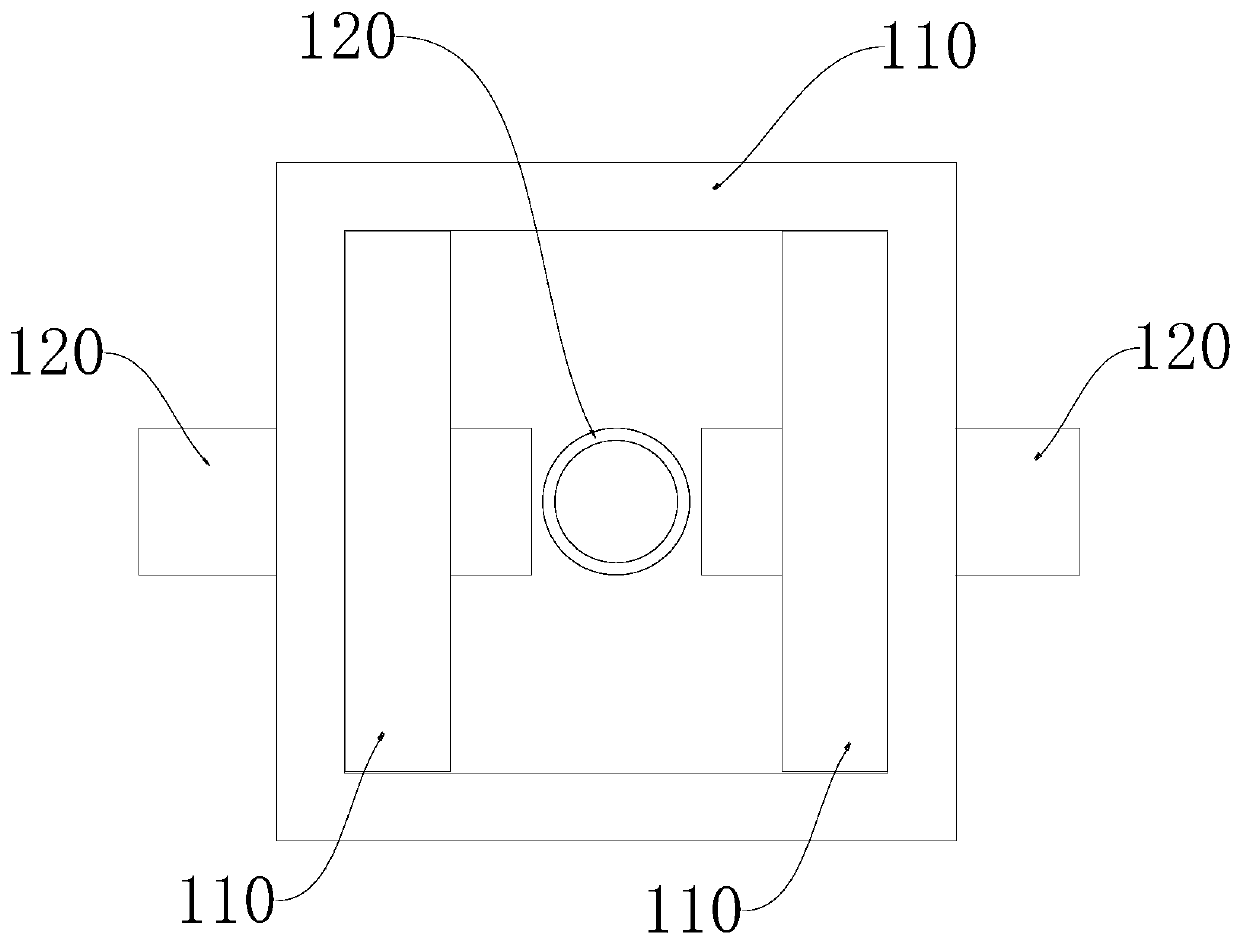

[0067] Such as Figure 2-5 As shown, a magnetic control device G is included, and the magnetic control device G is provided with at least two pairs of coil pairs 100;

[0068] Wherein, a pair of the coil pair 100 is provided with two groups of polarized coil groups, and one group of the polarized coil groups is provided with two sub-coils; the two sub-coils of the same group are arranged in parallel and facing each other, and the wires are wound in the same direction. , a unidirectional polarization zone is formed between the two sub-coils of the same group; the sub-coils of the two polarized coil groups of the same pair are parallel to each other, and the two polarized coil groups of the same pair The wires are wound in opposite directions, and the unidirectional polarization regions of the two polarized coil groups of the same pair cross each other to form a bidirectional polarization region;

[0069] The other pair of coils 100 is also provided with two push coils 120, the...

Embodiment 2

[0108] figure 2 with 3 A planar magnetron device is shown. There are two pairs of coils 100, and the centerlines of the two pairs of coils 100 are perpendicular to each other. A cube-shaped winding formwork is provided inside, and the polarized coil groups are all wound on the winding formwork, and the push coil 120 is threaded on the surface of the corresponding winding formwork. For the convenience of expression, the centerlines of the two groups of coil pairs 100 are respectively marked as x-axis and y-axis, and then there are two polarized-pushing coil groups with opposite driving directions on the x-axis and y-axis respectively. The polarized coil groups in the four driving directions are sequentially recorded as X+ polarized coil group, X-polarized coil group, Y+ polarized coil group and Y-polarized coil group, and the driving coils in the four driving directions are sequentially recorded as X+ Push Coil, X-Push Coil, Y+ Push Coil, and Y-Push Coil. The X+ polarized ...

Embodiment 3

[0111] Figure 5 Shown is a three-dimensional magnetic control device. There are three groups of coil pairs 100 , the three groups of coil pairs 100 enclose the cubic magnetic control area 130 , and the centerlines of the three coil pairs 100 are perpendicular to the center of the magnetic control area 130 . A square hollow winding formwork is provided inside, and the polarized coil groups are all wound on the winding formwork, and the driving coil 120 is threaded on the surface of the corresponding winding formwork.

[0112] For the convenience of expression, the centerlines of the three groups of coil pairs 100 are respectively marked as x-axis, y-axis and z-axis, and then two polarized-push coils with opposite driving directions are respectively arranged on the x-axis, y-axis and z-axis Group. The polarized coil groups in the six driving directions are sequentially recorded as X+ polarized coil group, X-polarized coil group, Y+ polarized coil group, Y-polarized coil group...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com