In-situ curing biodegradable anchor with reinforcement

A biodegradable, bioceramic technology, applied in ligaments, fixators, internal fixators, etc., can solve problems such as anchors placed close together, weak interfaces, and anchors not tightly pressed against each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

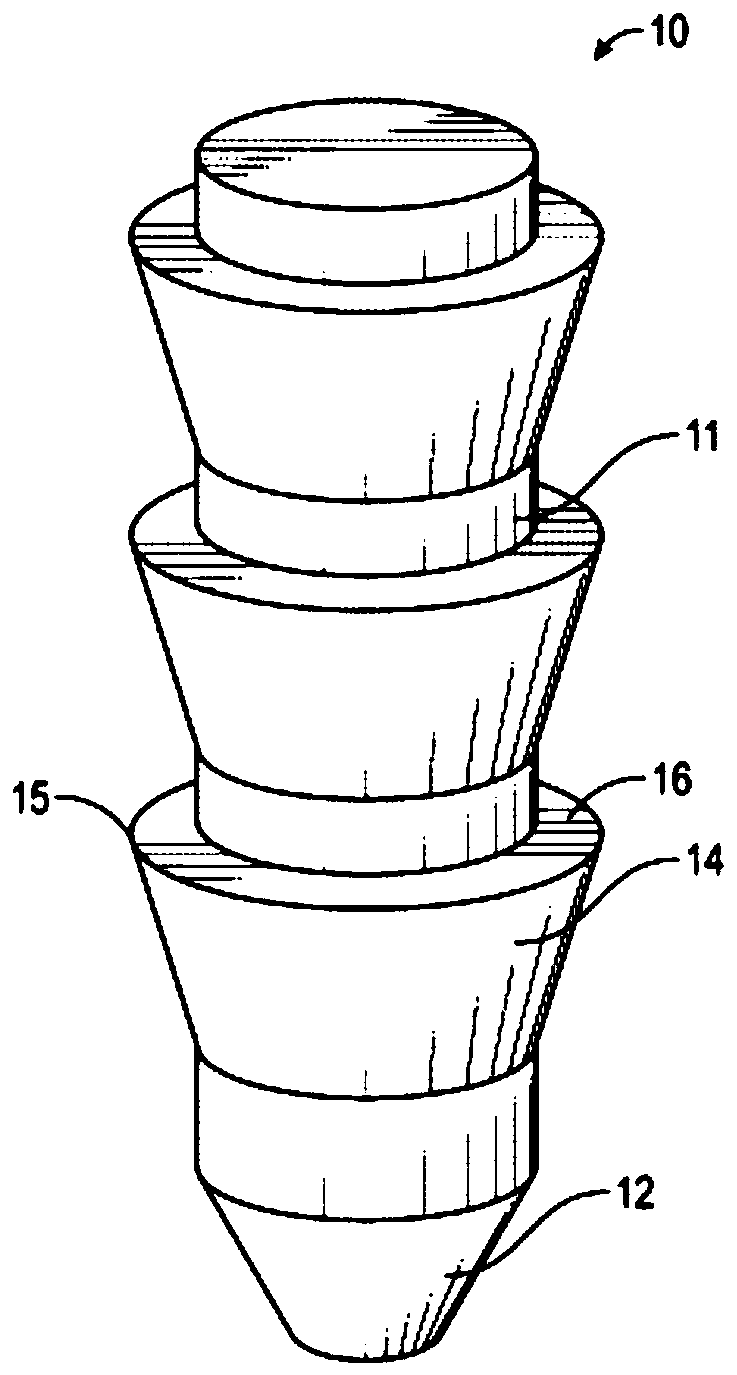

[0040] refer to figure 1 , the exemplary anchor component 10 takes the form of an elongated member defining a substantially tapered member 12 at its distal end. The cone 12 serves to position and align the anchor member 10 relative to the fixation site. The cone 12 may be integrally formed with or attached to the body 11 of the anchor member 10 . The conical shape of the cone 12 transitions to a diameter smaller than the diameter of the main body 11 . In another embodiment, the diameter of the tapered member 12 is substantially equal to the diameter of the proximal portion of the body 11 .

[0041] exist figure 1 In the exemplary embodiment shown, the body 11 is cylindrical (or substantially cylindrical). However, the main body 11 can be made in various shapes, such as but not limited to conical shape or with facets (eg hexagonal, triangular, square or other shapes).

[0042] In an exemplary embodiment, at least one protrusion 14 is defined on the exterior of the body 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com