Sewage treatment method after sludge treatment

A sewage treatment method and sludge treatment technology, applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage treatment equipment, etc. Large consumption of carbon fillers, etc., to achieve the effect of easy molding, easy to strengthen the micro-electrolysis reaction, and shorten the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The sewage treatment method after sludge treatment provided by the present invention will be further described in detail and completely below in conjunction with the examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0039] The experimental methods in the following examples are conventional methods unless otherwise specified. The experimental materials used in the following examples were purchased from the market unless otherwise specified.

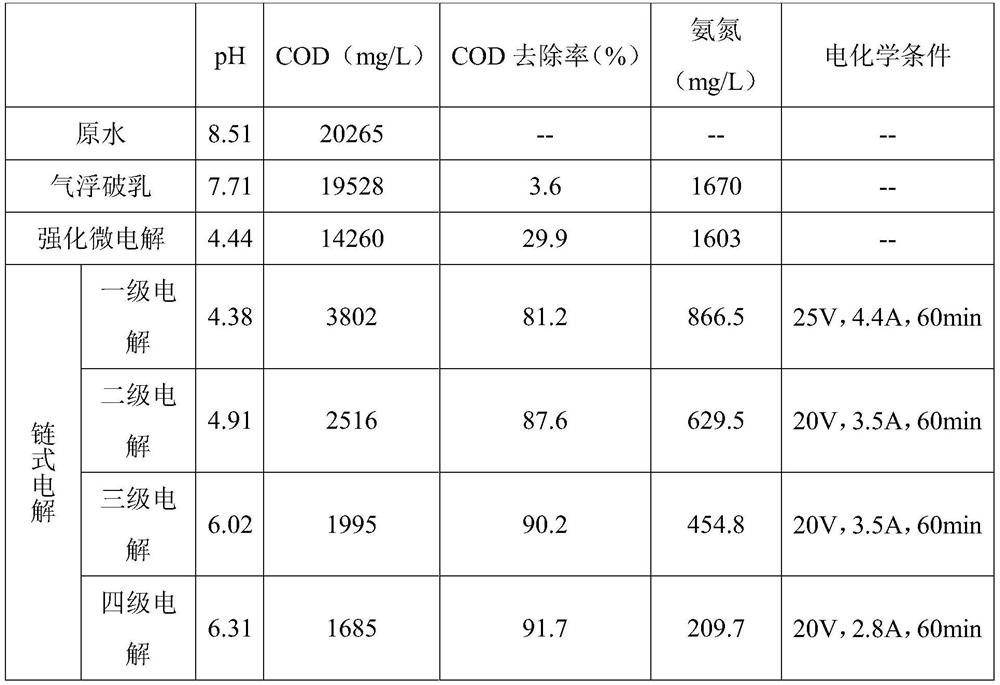

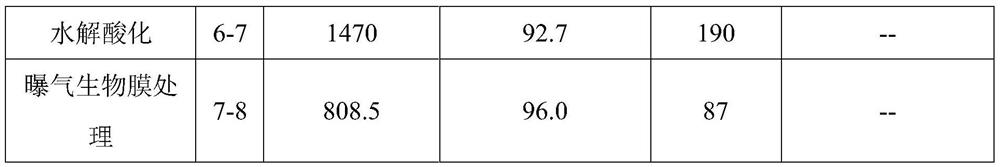

[0040] The method of the present invention treats the sewage collected after sludge pyrolysis, because the components in the sewage are complex, containing more oily substances and small particles of impurities such as water-insoluble organic matter, colloids and suspended matter, so a composite treatment method is adopted , the sewage is treated sequentially in multiple steps. After the sewage is separated from the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com