Single crystal copper foil and preparation method thereof

A copper foil and single crystal technology, applied in the field of single crystal copper foil and its preparation, can solve the problems of high cost and low copper foil efficiency, and achieve the effects of improving performance, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] One aspect of the present invention provides a method for preparing single crystal copper foil, comprising: placing the copper foil in an oxidizing gas atmosphere for pre-oxidation treatment to completely oxidize the surface of the copper foil; placing the fully oxidized copper foil on the surface in a reducing Reduction treatment was carried out in an inert gas atmosphere to obtain single crystal copper foil.

[0023] According to the present invention, the copper foil is used as an effective substrate and catalyst for growing graphene, and a high-quality graphene sample can be prepared by a chemical vapor deposition (CVD) method. The orientation of copper foil, grain boundaries and other properties will affect the performance of graphene to a certain extent. The preparation of single crystal copper foil can significantly reduce the influence of grain boundaries on graphene, and the graphene grown on single crystal copper foil can achieve seamless splicing. Existing c...

Embodiment 1

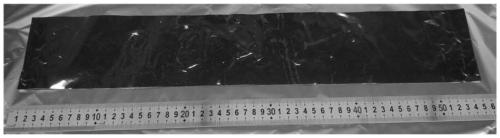

[0035] Put ordinary commercially available copper foil (purchased from Kunshan Luzhifa Electronic Technology Co., Ltd.) together with the carrier into the tube furnace, pass air into it and pre-oxidize at 300°C for 60 minutes to completely oxidize the surface of the copper foil , the organic matter attached to the copper foil surface is oxidatively decomposed and desorbed. Then, hydrogen gas is introduced into the tube furnace, and the temperature is raised to 1000°C. After reduction treatment for 30 minutes, the copper oxide on the surface of the copper foil is completely reduced to obtain a single crystal copper foil with a single crystal size of 10 cm.

Embodiment 2

[0037] Put ordinary commercially available copper foil (the copper foil is purchased from Kunshan Luzhifa Electronic Technology Co., Ltd.) together with the carrier into the tube furnace, pass air into it and pre-oxidize at 400°C for 30 minutes to completely oxidize the surface of the copper foil , the organic matter attached to the copper foil surface is oxidatively decomposed and desorbed. Then, hydrogen gas is introduced into the tube furnace, and the temperature is raised to 800°C. After reduction treatment for 5 minutes, the copper oxide on the surface of the copper foil is completely reduced to obtain a single crystal copper foil with a single crystal size of 11 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com