Municipal road bottom hardening method

A technology for municipal roads and sidewalks, applied in the field of road construction, can solve the problems of weakened water seepage performance, poor water seepage performance, and water accumulation, and achieve the effects of reducing water accumulation, good drainage function, good load-bearing capacity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

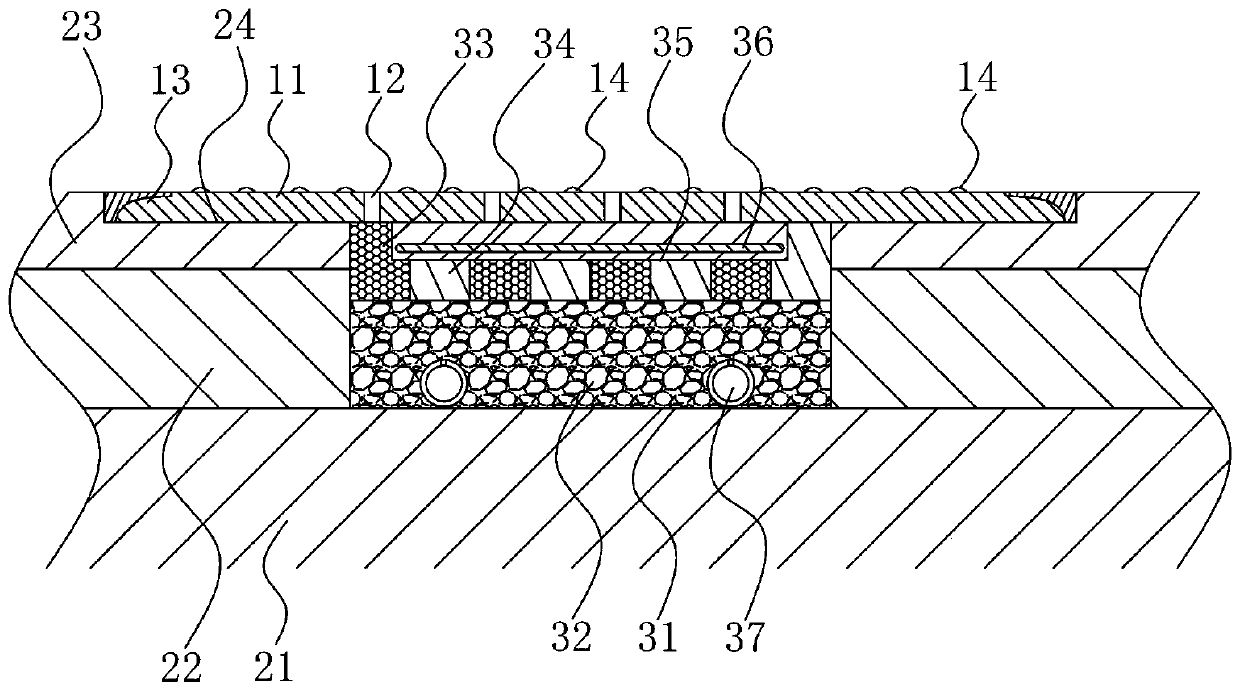

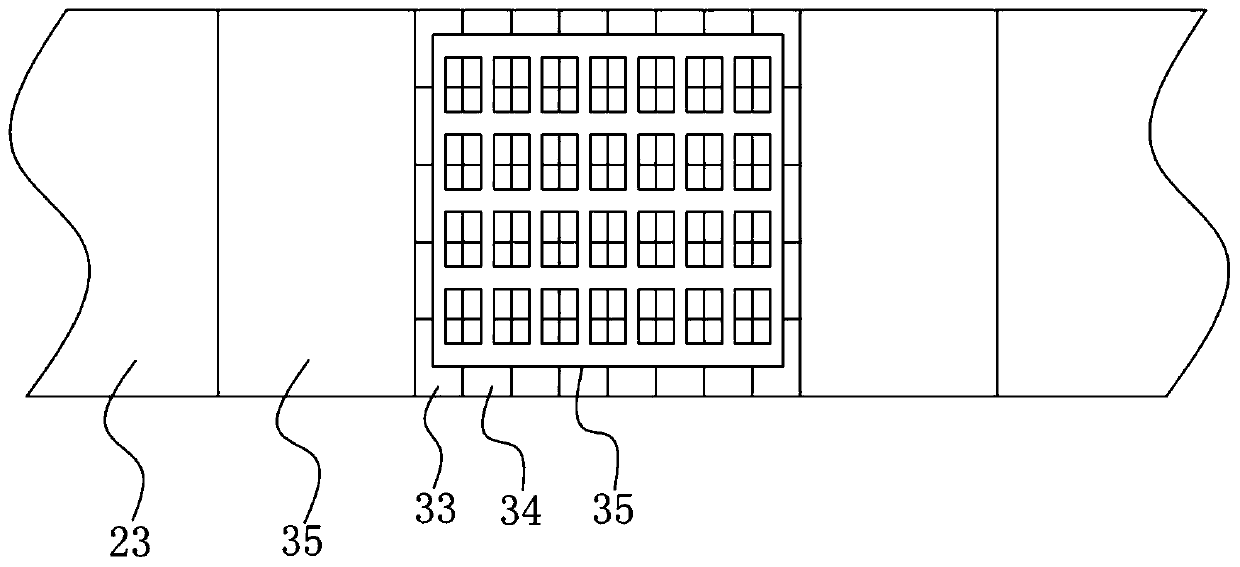

[0033] A method for hardening municipal roads, such as figure 1 and figure 2 shown, including the following steps:

[0034] S1. Prefabricated load-bearing plate 11: prefabricated metal load-bearing plate 11 in the factory, opened several water holes 12 on the load-bearing plate 11, welded the reinforcement plate 13 on the edge of the load-bearing plate 11, and welded the reinforcement plate 13 on the load-bearing plate 11 Anti-slip protrusions 14 are formed on the upper surface by spot welding, and the anti-slip protrusions 14 are polished to remove burrs;

[0035] S2, leveling the soil layer 21: excavating the raised soil, and then compacting the soil layer 21; in this embodiment, a compacting machine is used to compact the soil layer 21;

[0036] Laying the water stabilizing layer 22: laying the water stabilizing layer 22 above the soil layer 21, pressing the upper surface of the water stabilizing layer 22 to flatten; in this embodiment, the water stabilizing layer 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com