Waterproof testing device

A technology of waterproof test and water return device, which can solve the problems of inability to adjust the position of the nozzle by detecting the appearance of fluid at the leakage point, non-electric variable control, and instruments, etc., to achieve recyclable utilization and simple structure of the device , the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

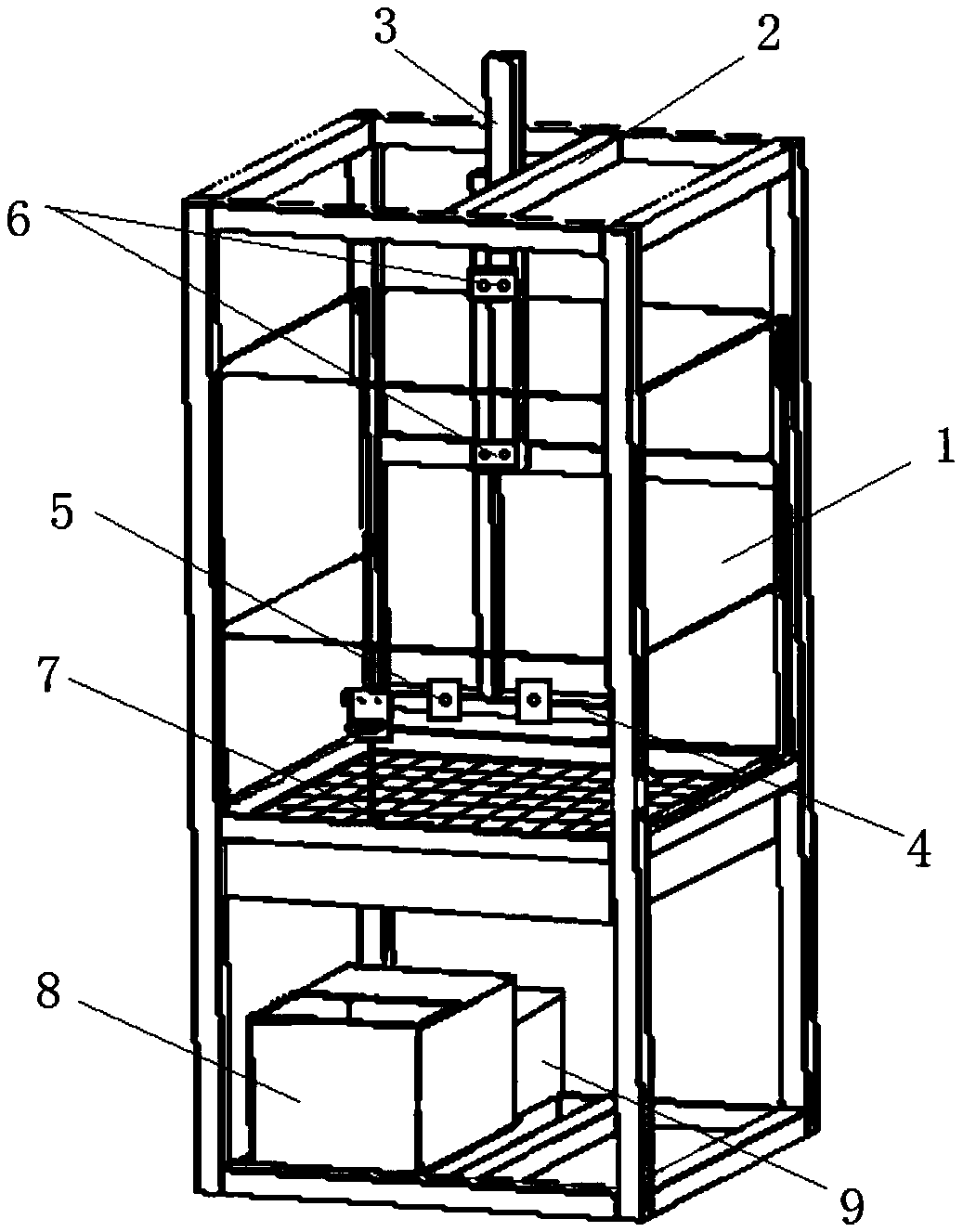

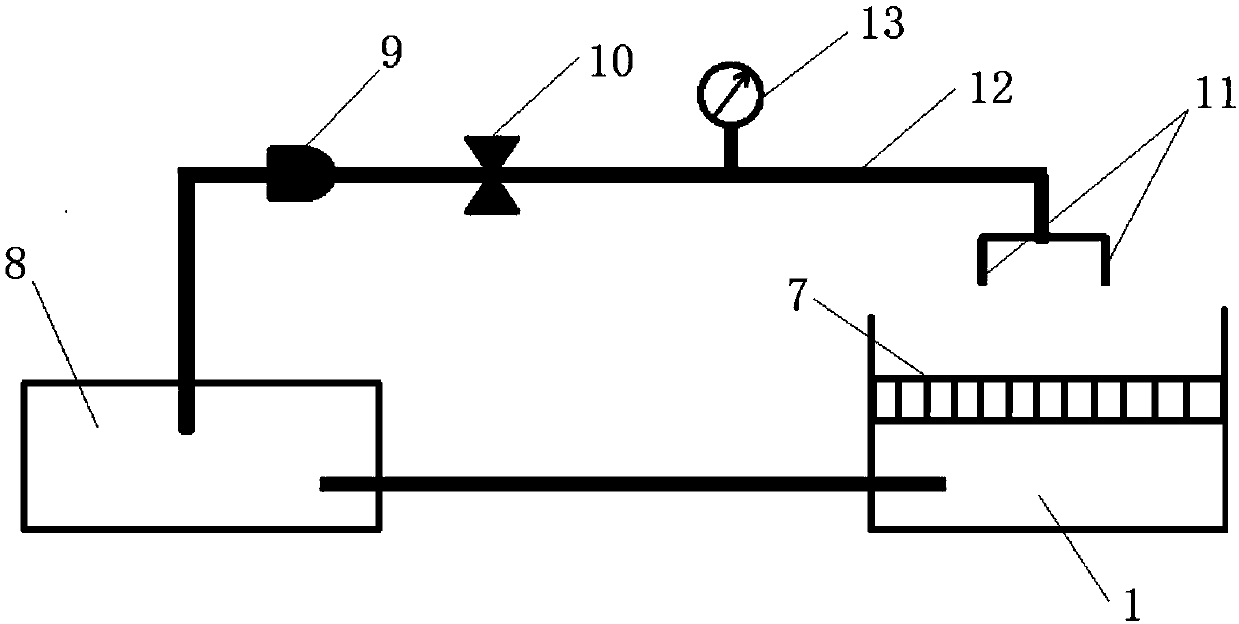

[0024] like figure 1 , 2 As shown, a waterproof test device is suitable for the waterproof test of electronic modules in automobiles, including a test box 1, a water spray device and a water return device. The water spraying device is arranged in the test chamber 1 and includes a nozzle 11 and an adjusting rod assembly connected to the nozzle 11 . The adjusting rod assembly includes a horizontal rod 2, a lifting rod assembly 3 with adjustable bottom height and a nozzle adjusting rod 4. The horizontal rod 2 is horizontally arranged on the top of the test chamber 1. The lifting rod assembly 3 is vertically connected with the horizontal rod 2. The nozzle adjusting rod 4. It is horizontally arranged at the bottom of the lifting rod assembly 3. The nozzle 11 is arranged on the nozzle adjusting rod 4 and can change its position along the axial direction of the nozzle adjusting rod 4. The number of nozzles 11 is not less than two. In this embodiment, there are 2 nozzles 11. The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com