Intelligent workshop production processing system and method based on digital twinning and machine learning technologies

A machine learning and processing system technology, applied in the direction of digital control, general control system, control/regulation system, etc., can solve the problem of less application of industrial products, and achieve the effect of processing process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

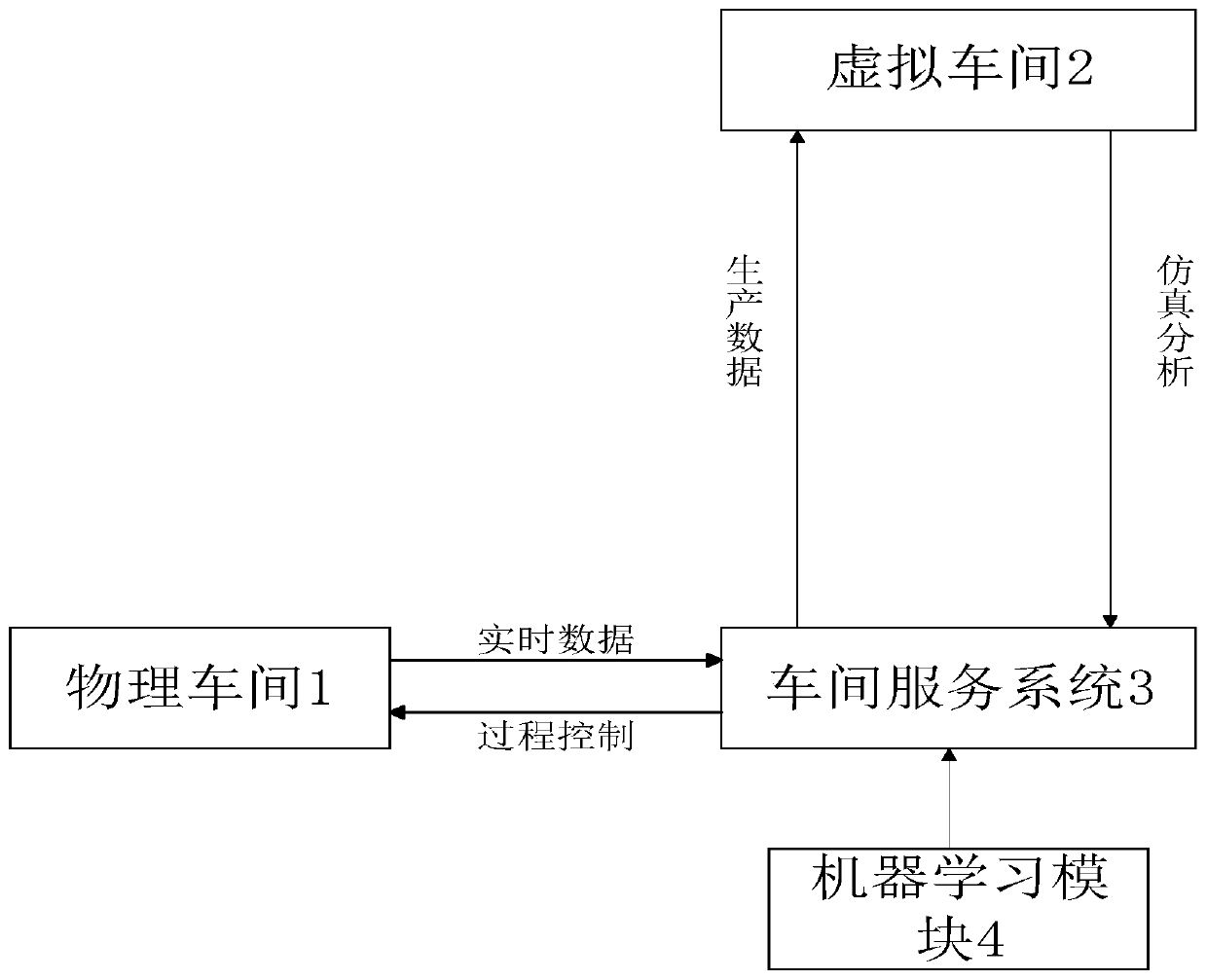

[0022] Such as figure 1 Shown is an intelligent workshop production and processing system based on digital twins and machine learning technology. The intelligent workshop production and processing system consists of a three-tier architecture and one module, namely the physical workshop (1) and the workshop service system (3) Connect the virtual workshop (2) and the machine learning module (4).

[0023] The physical workshop (1) of the present invention refers to the physical workshop involved in the processing of the workpiece, including parts, components, workpieces, processing equipment, materials, sensors, actuators, etc., in addition to the production and processing functions of a traditional workshop , It also has the ability to perceive access and fusion of heterogeneous multi-source real-time data; the workshop service system (3) is a collection of various data-driven service system functions, and is mainly responsible for the intelligentization of the workshop driven by th...

Embodiment 2

[0025] The intelligent workshop processing method based on digital twins and machine learning technology adopts the above-mentioned system for operation, and the operation steps are as follows:

[0026] 1) The real-time data of the physical workshop is transferred to the workshop service system, and the workshop service system generates initial production activities based on the real-time data and feeds back to the physical workshop;

[0027] 2) The workshop service system transfers production data to the virtual workshop, which simulates the operation status of the physical workshop, monitors the running time, real-time status, and number of workpieces of the machine tool, and feeds back the simulation analysis results to the workshop service system. The workshop service system optimizes the simulation analysis results based on real-time data, and transmits them to the virtual workshop again, and iterates until the production plan is optimal;

[0028] 3) Based on the obtained produc...

Embodiment 3

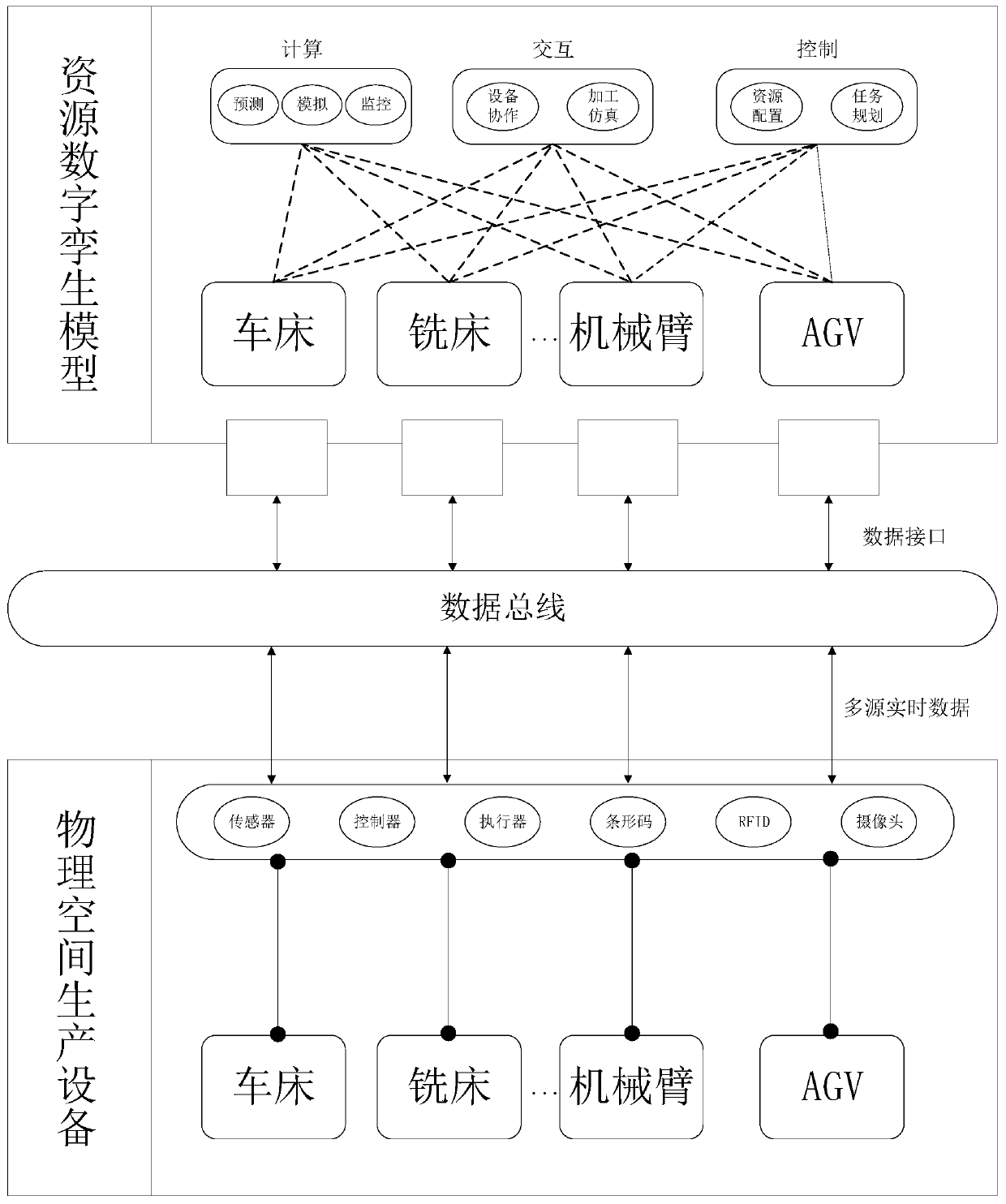

[0031] Such as figure 2 As shown, this embodiment first constructs a virtual workshop based on a physical workshop. The workshop service system generates a production plan based on real-time data of the physical workshop and transmits the production plan to the virtual workshop. The virtual workshop performs simulation activities according to the established production process flow. At present, the machine tool data acquisition and monitoring software is available in the workshop, which can monitor the real-time status, running time, and number of workpieces of the machine tool.

[0032] In the process of processing the workpiece, according to the different processing surfaces and the required processing accuracy, different types of machine tools such as lathes, grinders, milling machines, planers, boring machines, etc. will inevitably be used in the processing. The sequence and process planning have been simulated and optimized in the virtual workshop, which can improve the eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com