Damping modeling and checking method in finite element simulation process of steam turbine generator

A technology of turbo-generator and modeling method, which is applied in design optimization/simulation, electrical digital data processing, computer-aided design, etc. test, improve the calculation accuracy, and facilitate the implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] Taking a domestic QFSN-300-2 turbogenerator as an example, the validity of the damping modeling method in the finite element simulation process proposed by the present invention and the damping parameter verification method based on the principle of rotor AC impedance is verified. The basic parameters of the QFSN-300-2 turbogenerator are shown in Table 1. The measured rotor AC impedance of the generator is 9.54Ω under the AC voltage of 150V and 50Hz.

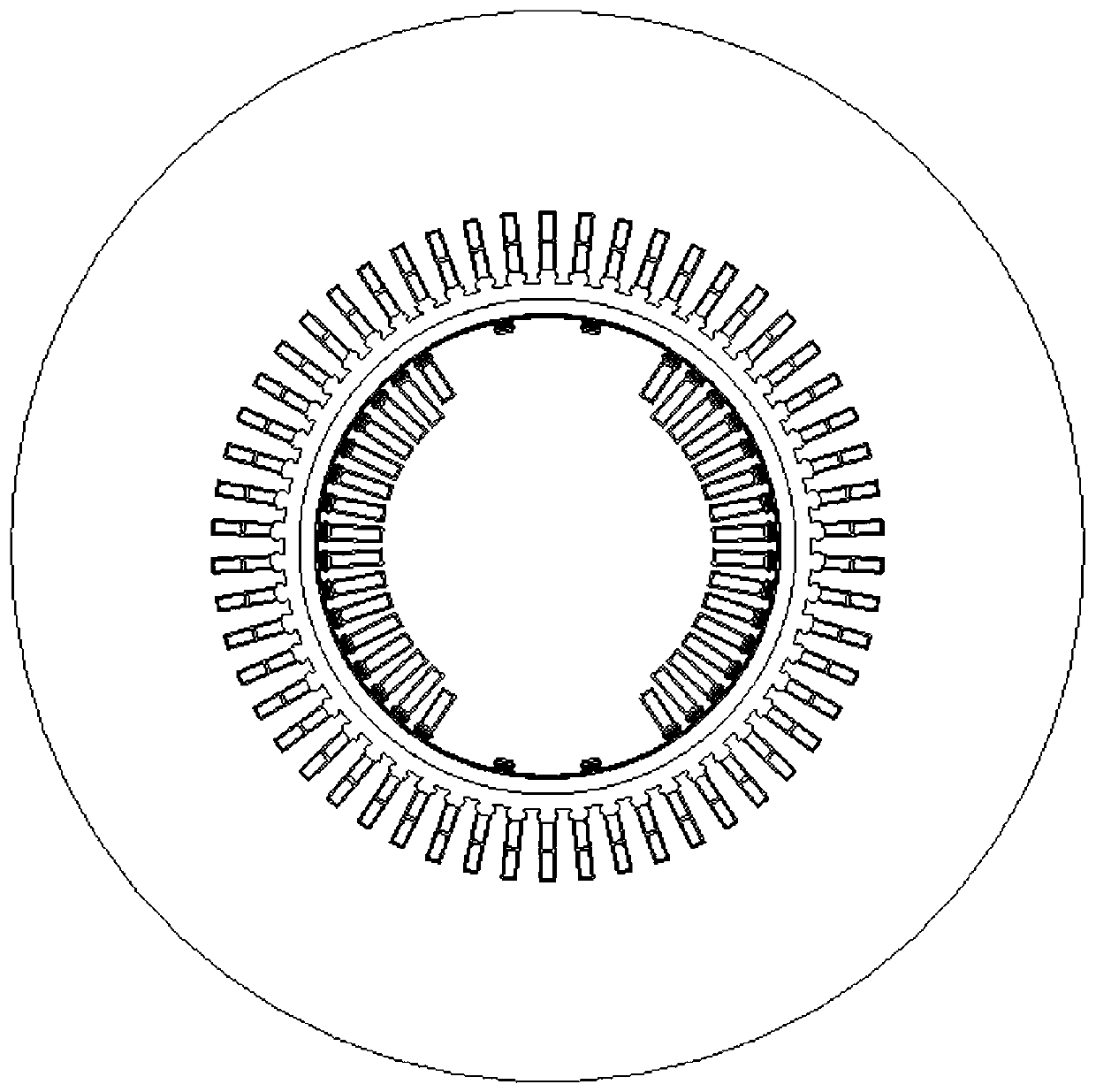

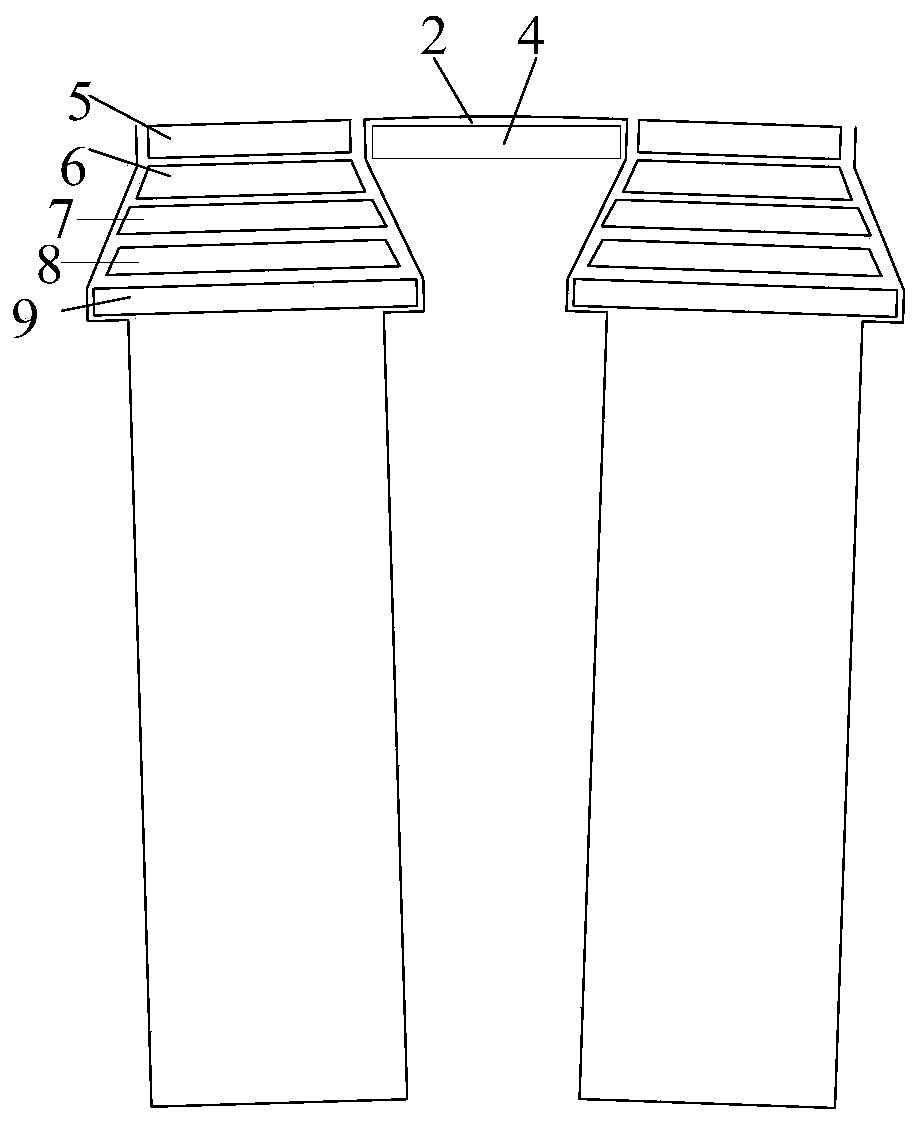

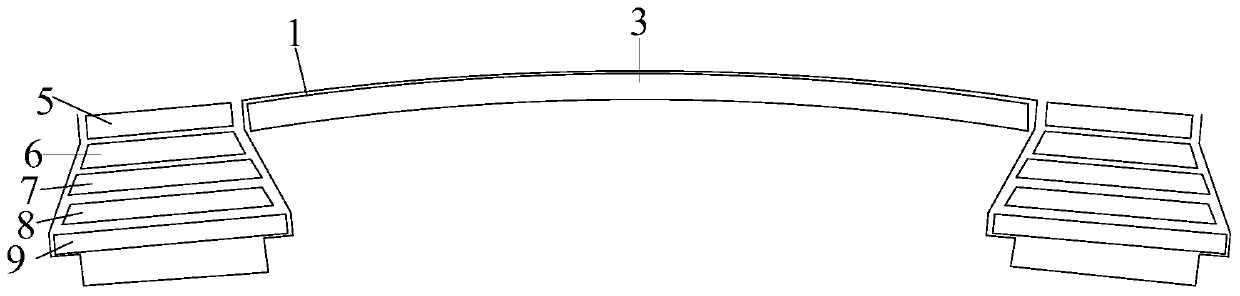

[0045] First, according to the B-H curve and structural data of the generator, the 2D model of the generator is established by using finite element simulation software, see figure 1 . In the model attribute setting stage, the known BH characteristic curve data is used to define the ferromagnetic material properties, and the air gap permeability is set as the vacuum permeability....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com