A motor cooling air duct with improved fatigue characteristics and sealing characteristics and its manufacturing method

A technology of motor cooling and fatigue characteristics, applied in the field of electric machinery, can solve problems such as poor consolidation reliability, poor flange butt joint sealing, poor fatigue resistance, etc., and achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

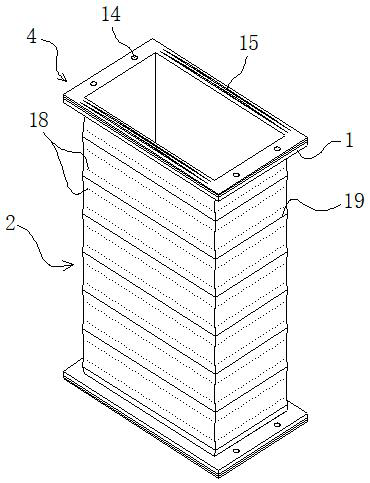

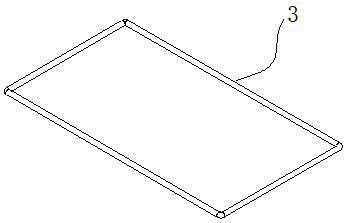

[0050] Such as figure 1 As shown in —4, a motor cooling air duct that improves the sealing performance and fatigue performance includes an external flange 4, a cloth square tube 2, and a rectangular rib frame 3; the external flange 4 includes a rectangular frame-shaped flange base plate 1, and the layout The square tube 2 is lined on a number of rectangular ribs 3 to form a flexible square tube. The rectangular perimeters at both ends of the square tube 2 are sealed with a rectangular frame edge of a flange substrate 1 to form an air duct. The above-mentioned square tube 2 is made of an inner layer. 5 and the outer layer of cloth 6, the rectangular rib frame 3 is lined between the inner layer of cloth 5 and the outer layer of cloth 6. On the one hand, compared with the motor cooling air duct made of single-layer cloth pipe, the air duct made of double-layer cloth square pipe has a significantly longer service life; On the one hand, it is convenient to find out the problems of...

Embodiment 2

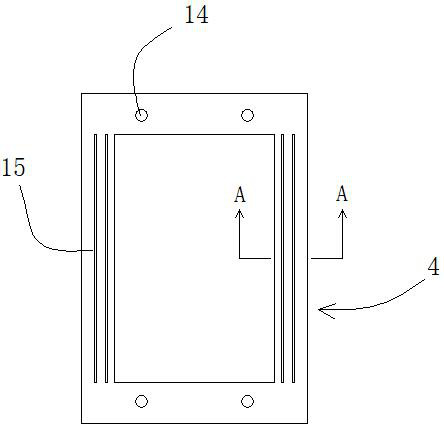

[0078] Such as Figure 8 As shown, the rectangular frame-shaped external flange 4 is different from the first embodiment in that: four bolt holes 14 for fastening connection with the object flange are respectively arranged at four right-angle parts of the external flange 4; Two sealing flanges 15 are provided between two adjacent bolt holes 14 . This is mainly for when the length of the two short sides of the rectangular external flange is long, the middle area of the short side is far away from the fastener, and the fastening pressure is not enough when docking with the target flange, resulting in poor airtightness.

Embodiment 3

[0080] Such as Figure 9 As shown, the rectangular frame-shaped external flange 4 differs from the first embodiment in that only one sealing flange 15 is provided on the two opposite long sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com